Cryogenic Pump Market Size 2024-2028

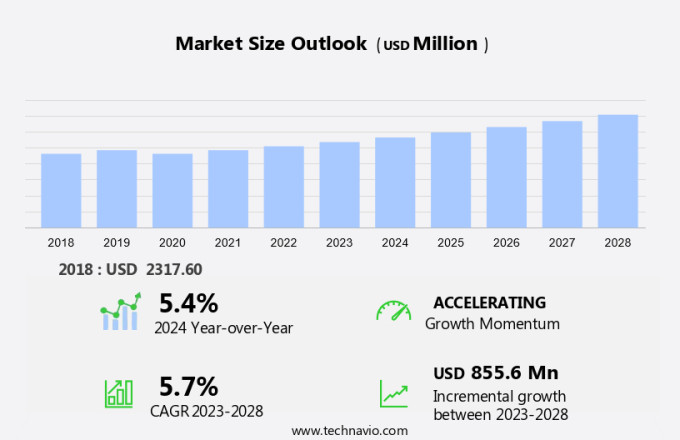

The cryogenic pump market size is forecast to increase by USD 855.6 million, at a CAGR of 5.7% between 2023 and 2028.

- The market is driven by the expanding water and wastewater industry, which necessitates the use of advanced cryogenic pumps for efficient and reliable processing. Another significant factor fueling market growth is the increasing demand for pump repair and remanufacture from high-performance applications. However, the market faces challenges due to the volatility in raw material prices, which can impact the cost structure and profitability of pump manufacturers.

- To capitalize on market opportunities, companies must focus on innovation and cost optimization, while also addressing the challenge of price fluctuations through strategic sourcing and supply chain management. Additionally, collaboration with industry players and investment in research and development can help companies stay competitive and meet the evolving demands of the market.

What will be the Size of the Cryogenic Pump Market during the forecast period?

Explore in-depth regional segment analysis with market size data - historical 2018-2022 and forecasts 2024-2028 - in the full report.

Request Free Sample

The market is characterized by its continuous evolution and dynamic nature, driven by the expanding applications across various sectors. High-performance computing relies on cryogenic cooling for optimal efficiency, while cryogenic treatment and optimization are crucial in semiconductor manufacturing. Cryogenic processing finds extensive use in biomedical and scientific research, as well as in space exploration and cryogenic freezing for preservation. Cryogenic safety and handling are paramount in ensuring the reliability of these systems. Cryogenic maintenance, transfer, and certification are essential components of their operation, ensuring seamless integration with high-vacuum systems, cryogenic piping, and cryogenic valves. The use of cryogenic fluids, such as liquid nitrogen and helium, is prevalent in cryogenic insulation, cryogenic spraying, and cryogenic cleaning.

Cryogenic design plays a significant role in optimizing cryogenic efficiency and ensuring the safe handling of cryogenic materials. Cryogenic machining and grinding are essential in producing components for cryogenic engineering applications, such as superconducting magnets and cryogenic sensors. Cryogenic testing and simulation are integral to the development and improvement of these systems. The market for cryogenic pumps is further propelled by the increasing demand for low-temperature applications, including cryogenic cooling, cryogenic processing, and cryogenic preservation. Cryogenic actuators and cryogenic standards are essential in maintaining the performance and safety of these systems. The ongoing development of cryogenic technology continues to unfold, with new applications and advancements shaping the market landscape.

How is this Cryogenic Pump Industry segmented?

The cryogenic pump industry research report provides comprehensive data (region-wise segment analysis), with forecasts and estimates in "USD million" for the period 2024-2028, as well as historical data from 2018-2022 for the following segments.

- Type

- Positive displacement pump

- Dynamic pump

- Geography

- North America

- US

- Europe

- Germany

- Russia

- APAC

- China

- India

- Rest of World (ROW)

- North America

By Type Insights

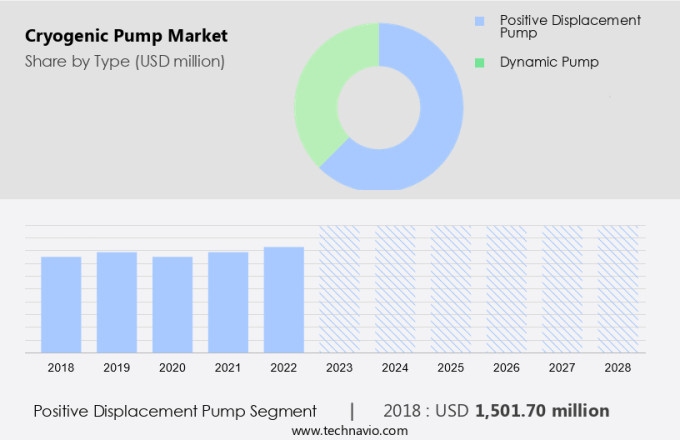

The positive displacement pump segment is estimated to witness significant growth during the forecast period.

In the realm of advanced technology and scientific research, the application of cryogenic systems continues to expand, driven by the demands of various industries and scientific disciplines. Cryogenic pumps play a pivotal role in this domain, enabling ultra-high vacuum, cryogenic safety, and efficient handling of cryogenic fluids. These pumps are integral to semiconductor manufacturing, where they facilitate cryogenic spraying and maintenance, ensuring the production of high-performance computing components. In the scientific community, cryogenic processing and cryogenic testing are essential for biomedical research and scientific research, enabling the preservation of biological samples and the exploration of low-temperature phenomena.

Cryogenic logistics and transfer are crucial for the transportation and storage of cryogenic fluids, such as liquid helium and liquid nitrogen, in industries like space exploration, cryogenic metallurgy, and cryogenic freezing. Cryogenic pumps are also essential in cryogenic engineering, where they contribute to the design and optimization of high-vacuum systems, cryogenic insulation, and cryogenic cooling. In addition, they are employed in cryogenic certification, cleaning, and simulation, ensuring the reliability and safety of cryogenic systems. Cryogenic valves, sensors, and actuators are integral components of these systems, enabling precise control and monitoring. The use of cryogenic pumps extends to various applications, including superconducting magnets, particle accelerators, and cryogenic standards.

Their efficiency and reliability make them indispensable in maintaining the performance and longevity of these complex systems. Cryogenic materials, machining, and cooling are also essential in the production and maintenance of these components. As the demand for advanced technologies and scientific research continues to grow, the market for cryogenic pumps and related technologies is poised for significant expansion. The integration of cryogenic systems in high-tech industries, scientific research, and space exploration will drive the development of more efficient, reliable, and cost-effective solutions. The future of cryogenic technology is bright, and the role of cryogenic pumps in enabling these advancements is undeniable.

The Positive displacement pump segment was valued at USD 1501.70 million in 2018 and showed a gradual increase during the forecast period.

Regional Analysis

APAC is estimated to contribute 45% to the growth of the global market during the forecast period.Technavio’s analysts have elaborately explained the regional trends and drivers that shape the market during the forecast period.

In the Asia Pacific region, the economy is witnessing substantial growth, leading to the expansion of industrial infrastructure. This development is significantly influencing the market's growth trajectory. Key factors fueling this market's growth include the increasing industrialization, positive economic growth, and rising demand for liquefied natural gas (LNG). Furthermore, the adoption of renewable energy sources is anticipated to generate substantial growth opportunities. Emerging smart cities and infrastructure development in countries like India and China are creating vast market potential. The promotion of green industrialization and the utilization of renewable energies by developed countries are also driving the market's growth in APAC.

The market encompasses various applications, including ultra-high vacuum, cryogenic safety, cryogenic handling, semiconductor manufacturing, cryogenic spraying, cryogenic maintenance, cryogenic processing, cryogenic logistics, biomedical research, scientific research, cryogenic reliability, space exploration, cryogenic freezing, cryogenic metallurgy, cryogenic valves, cryogenic storage, high-vacuum systems, cryogenic efficiency, cryogenic piping, cryogenic grinding, cryogenic testing, cryogenic preservation, superconducting magnets, low-temperature applications, cryogenic transfer, cryogenic certification, cryogenic cleaning, cryogenic design, liquid helium, cryogenic insulation, cryogenic actuators, cryogenic simulation, cryogenic fluids, cryogenic sensors, vacuum insulation, high-performance computing, cryogenic treatment, cryogenic optimization, cryogenic materials, cryogenic machining, cryogenic cooling, and liquid nitrogen, among others. These applications are crucial to various industries, including cryogenic engineering, particle accelerators, and cryogenic standards.

The market's growth is underpinned by advancements in these applications, which are leading to increased efficiency, reliability, and cost savings.

Market Dynamics

Our researchers analyzed the data with 2023 as the base year, along with the key drivers, trends, and challenges. A holistic analysis of drivers will help companies refine their marketing strategies to gain a competitive advantage.

What are the key market drivers leading to the rise in the adoption of Cryogenic Pump Industry?

- The water and wastewater industry's advancements serve as the primary catalyst for market growth.

- The market is experiencing significant growth due to the increasing demand for low-temperature applications in various industries. Cryogenic pumps are essential components in the transfer, storage, and processing of cryogenic fluids, including liquid helium, nitrogen, and oxygen. The market's expansion is driven by the rising need for cryogenic cleaning, cryogenic certification, and the development of advanced cryogenic designs. Cryogenic insulation, cryogenic actuators, cryogenic sensors, and vacuum insulation are critical components of cryogenic systems that require high precision and reliability. The increasing use of these systems in research, healthcare, and industrial applications is fueling the market's growth.

- The global water treatment industry is a significant end-user of cryogenic pumps, as they are used in the cooling and separation processes of water treatment plants. With the growing global population and the increasing demand for clean water, investments in water treatment infrastructure are on the rise, creating new opportunities for the market. In conclusion, the demand for cryogenic pumps is expected to continue growing due to their increasing use in various industries, particularly in water treatment and low-temperature applications. The market's growth is driven by factors such as the rising demand for clean water, advancements in cryogenic technology, and the increasing use of cryogenic fluids in various industries.

What are the market trends shaping the Cryogenic Pump Industry?

- The increasing demand for pump repair and remanufacturing services is a notable trend in high-performance applications. This need arises from the growing reliance on reliable and efficient equipment in various industries.

- In the realm of large-scale and capital-intensive industries, such as offshore oil and gas, chemical processing, and petrochemicals, pumping systems represent a substantial portion of the total investment cost. Given the high cost of replacement, many end-users prefer to opt for repair or remanufacturing of these components. In the context of harsh and corrosive environments, material deposition technologies, including plasma arc welding and laser cladding, have emerged as viable solutions for restoring the functionality of worn-out mechanical components. These techniques, classified as material processing and coating methods, have gained significant traction in the repair and renovation of degraded pumping systems.

- Cryogenic engineering plays a crucial role in enhancing the performance of these materials. Cryogenic treatment, cryogenic optimization, and cryogenic cooling are essential processes in this regard. Liquid nitrogen, a widely used cryogenic material, plays a pivotal role in the cryogenic processing of various metals and alloys. The application of cryogenic engineering in industries like high-performance computing, particle accelerators, and cryogenic standards is on the rise. The importance of cryogenic engineering is further emphasized by its role in optimizing the efficiency and lifespan of critical components in these industries.

What challenges does the Cryogenic Pump Industry face during its growth?

- The volatility in raw material prices poses a significant challenge to the industry's growth trajectory. In order to maintain competitiveness and profitability, businesses must closely monitor and adapt to fluctuations in the prices of essential inputs. This market instability can lead to increased operational costs, supply chain disruptions, and decreased predictability for financial planning. Consequently, effective risk management strategies and strong supplier relationships are crucial for navigating this challenge and fostering long-term industry growth.

- The market experiences price volatility due to fluctuations in raw material costs, particularly for cast iron, bronze, stainless steel, aluminum, and copper. This can hinder the adoption of cryogenic pumps in price-sensitive emerging markets. Raw material prices have seen significant fluctuations in recent years, influenced by factors such as tax increases, additional tariffs, and production suspensions in metal-ore producing countries. These price changes can ripple through the entire supply chain, affecting the production and availability of cryogenic pumps. Moreover, different versions of cryogenic pumps utilize various types and sources of raw materials, further complicating price stability.

- Cryogenic safety, reliability, and maintenance are crucial factors in industries such as semiconductor manufacturing, cryogenic spraying, cryogenic processing, cryogenic logistics, biomedical research, and scientific research. Ensuring the highest cryogenic handling standards is essential to prevent potential hazards and maintain the integrity of the process. Cryogenic pumps play a vital role in these industries, and addressing raw material price instability is a significant challenge that must be addressed to ensure their continued growth and success.

Exclusive Customer Landscape

The cryogenic pump market forecasting report includes the adoption lifecycle of the market, covering from the innovator’s stage to the laggard’s stage. It focuses on adoption rates in different regions based on penetration. Furthermore, the cryogenic pump market report also includes key purchase criteria and drivers of price sensitivity to help companies evaluate and develop their market growth analysis strategies.

Customer Landscape

Key Companies & Market Insights

Companies are implementing various strategies, such as strategic alliances, cryogenic pump market forecast, partnerships, mergers and acquisitions, geographical expansion, and product/service launches, to enhance their presence in the industry.

Celeros Flow Technology - Celeros, a leading provider of advanced fluid handling solutions, introduces cryogenic pumps engineered for cryogenic applications. These pumps feature double mechanical seals, ensuring effective sealing of natural gas liquids (NGL), liquefied natural gas (LNG), liquefied petroleum gas (LPG), and other low-temperature fluids. The pumps' robust design guarantees reliable performance in extreme temperatures. Celeros' commitment to innovation and quality underpins the development of these pumps, which are integral to the cryogenic industry's success.

The industry research and growth report includes detailed analyses of the competitive landscape of the market and information about key companies, including:

- Celeros Flow Technology

- Cryostar

- Ebara Corp.

- FIVES SAS

- Flowserve Corp.

- INOX India Pvt. Ltd.

- Nikkiso Co. Ltd.

- PHPK Technologies

- Ruhrpumpen Group

- SEFCO AG

- Sehwa Tech Inc.

- SHI Cryogenics Group

- Sulzer Ltd.

- Sumitomo Heavy Industries Ltd.

- Technex Ltd.

- Vanzetti Engineering S.p.A.

Qualitative and quantitative analysis of companies has been conducted to help clients understand the wider business environment as well as the strengths and weaknesses of key industry players. Data is qualitatively analyzed to categorize companies as pure play, category-focused, industry-focused, and diversified; it is quantitatively analyzed to categorize companies as dominant, leading, strong, tentative, and weak.

Recent Development and News in Cryogenic Pump Market

- In February 2024, Cryo-Mechanic, a leading cryogenic pump manufacturer, introduced its new line of high-performance, magnetically driven cryopumps for the liquefied natural gas (LNG) industry. These pumps, which offer improved efficiency and reliability, mark a significant technological advancement in the market (Cryo-Mechanic Press Release, 2024).

- In June 2025, Air Liquide, a global leader in gases, technologies, and services, announced a strategic partnership with Cryo-Tech, a prominent cryogenic pump supplier. This collaboration aims to enhance Air Liquide's cryogenic pump offerings and strengthen its position in the LNG sector (Air Liquide Press Release, 2025).

- In October 2024, Linde plc, a leading industrial gases and engineering company, completed the acquisition of Cryo-Tech, a major cryogenic pump manufacturer. This acquisition significantly expands Linde's cryogenic pump portfolio and enhances its capabilities in the LNG market (Linde plc Press Release, 2024).

- In March 2025, the European Union (EU) approved new regulations to boost the adoption of renewable hydrogen and its associated infrastructure, including the use of cryogenic pumps. This initiative is expected to create substantial growth opportunities for the market in Europe (European Commission Press Release, 2025).

Research Analyst Overview

- The cryogenic market encompasses a range of applications, from cryogenic refrigeration and cryogenic liquefaction to cryogenic separation and purification. Cryogenic control systems play a crucial role in managing the complex thermodynamics and pressure conditions associated with these processes. Strict safety regulations govern the handling of cryogenic vapor and liquid, ensuring safe and efficient operations. Cryogenic environmental impact is a growing concern, with researchers focusing on minimizing the carbon footprint of cryogenic processes through optimization and cryogenic cost analysis. Cryogenic data acquisition and automation enable real-time monitoring and modeling of cryogenic fluid dynamics, mass transfer, and temperature. Cryogenic industry associations and market research firms provide valuable insights into the latest trends and advancements in the field, including cryogenic simulation, cryogenic level measurement, and cryogenic density analysis.

- Cryogenic gas, particularly hydrogen and nitrogen, are widely used in various industries, driving demand for cryogenic separation and purification technologies. Cryogenic cost analysis and optimization are essential to maintaining profitability, with cryogenic heat transfer and cryogenic pressure management playing key roles in reducing energy consumption and minimizing waste. Cryogenic modeling and simulation enable engineers to design and optimize cryogenic systems, enhancing efficiency and safety.

Dive into Technavio’s robust research methodology, blending expert interviews, extensive data synthesis, and validated models for unparalleled Cryogenic Pump Market insights. See full methodology.

|

Market Scope |

|

|

Report Coverage |

Details |

|

Page number |

137 |

|

Base year |

2023 |

|

Historic period |

2018-2022 |

|

Forecast period |

2024-2028 |

|

Growth momentum & CAGR |

Accelerate at a CAGR of 5.7% |

|

Market growth 2024-2028 |

USD 855.6 million |

|

Market structure |

Fragmented |

|

YoY growth 2023-2024(%) |

5.4 |

|

Key countries |

China, US, India, Russia, and Germany |

|

Competitive landscape |

Leading Companies, Market Positioning of Companies, Competitive Strategies, and Industry Risks |

What are the Key Data Covered in this Cryogenic Pump Market Research and Growth Report?

- CAGR of the Cryogenic Pump industry during the forecast period

- Detailed information on factors that will drive the growth and forecasting between 2024 and 2028

- Precise estimation of the size of the market and its contribution of the industry in focus to the parent market

- Accurate predictions about upcoming growth and trends and changes in consumer behaviour

- Growth of the market across APAC, North America, Europe, Middle East and Africa, and South America

- Thorough analysis of the market’s competitive landscape and detailed information about companies

- Comprehensive analysis of factors that will challenge the cryogenic pump market growth of industry companies

We can help! Our analysts can customize this cryogenic pump market research report to meet your requirements.