Test Bench Market Size 2024-2028

The test bench market size is forecast to increase by USD 327.7 million at a CAGR of 4.36% between 2023 and 2028.

- The market is experiencing significant growth due to the increasing demand for semiconductors in various industries, particularly in the context of Industry 4.0 integration. This trend is driving market expansion as advanced test benches become essential for ensuring the quality and reliability of semiconductor devices. However, the high cost of developing and maintaining these sophisticated test solutions poses a challenge for market growth.

- Companies must navigate the challenge of investing in advanced technology while maintaining cost competitiveness. The market is also shifting toward cloud-based test bench solutions, offering greater flexibility, scalability, and cost efficiency. Overall, growth is driven by the expansion of the semiconductor industry and the adoption of Industry 4.0 technologies. However, the high cost of advanced test benches remains a key challenge that industry players must overcome to stay competitive.

What will be the Size of the Test Bench Market During the Forecast Period?

- The market encompasses a range of equipment used in the manufacturing and quality assurance processes for electronics, including circuit boards, sensors, and components. Two primary types of test benches are motorized test stands and manual test stands, each offering advantages in terms of quick testing and product quality. The increasing prevalence of autonomous, self-driving, and connected cars is driving demand for advanced test solutions in related industries.

- Moreover, torque test benches are particularly relevant for motorized systems, ensuring optimal performance and longevity. Lab bench equipment, such as oscilloscopes, multimeters, soldering irons, and wire cutters, are integral components of test bench setups, enabling precise measurements and modifications. Overall, the market continues to evolve in response to technological advancements and the need for higher product quality and extended product lifespan.

How is this Test Bench Industry segmented and which is the largest segment?

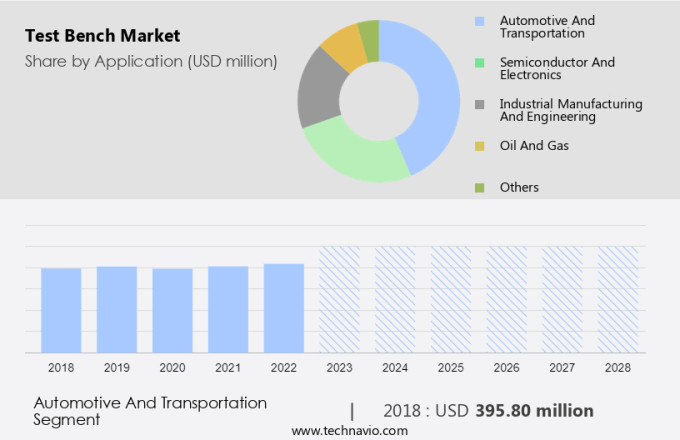

The test bench industry research report provides comprehensive data (region-wise segment analysis), with forecasts and estimates in "USD million" for the period 2024-2028, as well as historical data from 2018-2022 for the following segments.

- Application

- Automotive and transportation

- Semiconductor and electronics

- Industrial manufacturing and engineering

- Oil and gas

- Others

- Component

- Hardware

- Software

- Geography

- APAC

- China

- Japan

- Europe

- Germany

- UK

- North America

- US

- Middle East and Africa

- South America

- APAC

By Application Insights

- The automotive and transportation segment is estimated to witness significant growth during the forecast period.

The global test benches market is experiencing significant growth due to the increasing complexity of modern vehicles, particularly in the automotive industry. Automakers and suppliers require advanced testing solutions to evaluate the performance and quality of various vehicle components, including engines, transmissions, and sophisticated electronic systems such as autonomous driving technologies and electric powertrains. The growing demand for specialized test benches is driven by the need to ensure the reliability, safety, and regulatory compliance of these intricate components. As vehicles become more connected and autonomous, the importance of thorough testing to validate functionality and performance increases. Manufacturers utilize these testing platforms to verify the proper integration of these advanced systems into production vehicles.

Get a glance at the Test Bench Industry report of share of various segments Request Free Sample

The automotive and transportation segment was valued at USD 395.80 million in 2018 and showed a gradual increase during the forecast period.

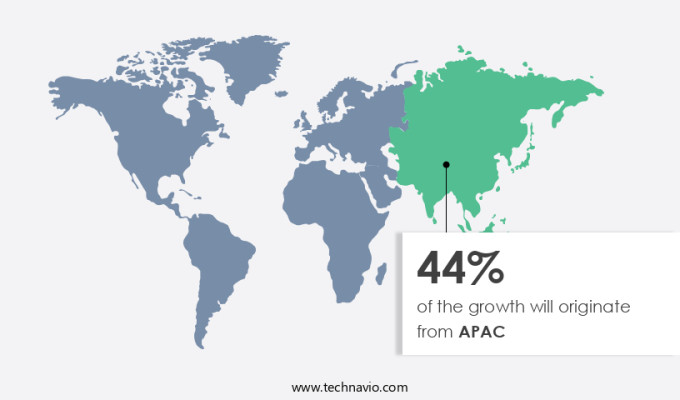

Regional Analysis

- APAC is estimated to contribute 44% to the growth of the global market during the forecast period.

Technavio's analysts have elaborately explained the regional trends and drivers that shape the market during the forecast period.

For more insights on the market share of various regions, Request Free Sample

In Asia Pacific (APAC), which is a significant manufacturing hub for the automotive, electronics, and consumer goods industries, the demand for advanced test benches is driven by the necessity to ensure the quality, safety, and performance of components and systems prior to their global distribution. APAC is a major player in the automotive sector, with countries such as China, Japan, South Korea, and India hosting large automotive manufacturing sectors. The region is also home to some of the world's leading electronics manufacturers, including Samsung, Haier, and Legend Holdings. Test benches play a crucial role in the testing of semiconductors, integrated circuits, sensors, and other electronic components used in various products. In the automotive industry, they ensure the reliability and efficiency of vehicles and their components, while in consumer electronics manufacturing, they help maintain high production standards and reduce the risk of defects. With the increasing focus on innovation and technological advancements, the demand for test benches in APAC is expected to continue growing.

Market Dynamics

Our test bench market researchers analyzed the data with 2023 as the base year, along with the key drivers, trends, and challenges. A holistic analysis of drivers will help companies refine their marketing strategies to gain a competitive advantage.

What are the key market drivers leading to the rise in adoption of Test Bench Industry?

High demand for semiconductors is the key driver of the market.

- The market is experiencing significant growth due to the increasing demand for circuit boards and supporting equipment in various industries, including electronics manufacturing, autonomous cars, and connected cars. This growth is driven by the expansion of these industries, which require advanced hardware segment such as torque test benches and motorized test stands for sensor testing and quality assurance. Manufacturers are under pressure to maintain high-quality standards and adhere to strict quality regulations. Test benches play a crucial role in ensuring the functionality and reliability of components, such as sensors, turbines, hydraulic hoses, safety valves, and other mechanical parts.

- Moreover, these testing machines provide stimuli and simulators to test components under various conditions, including combustion, force, torque, and manual testing on lab benches. Testing personnel rely on equipment such as oscilloscopes, multimeters, soldering irons, and wire cutters to perform quick testing and identify defects. The increasing production volumes in the semiconductor industry necessitate efficient and accurate testing processes. Test benches help maintain quality standards by ensuring that only functional components enter the supply chain. Therefore, the market in the US is a critical component of the manufacturing process in various industries. It provides essential equipment for testing and ensuring the functionality and reliability of components, enabling high-quality mass production and adherence to quality regulations.

What are the market trends shaping the Test Bench Industry?

Industry 4.0 integration boosting market growth is the upcoming trend in the market.

- Test benches play a crucial role in the manufacturing and quality assurance processes of various industries, including electronics, automotive, and energy. In the hardware segment, test benches are essential for evaluating the performance of circuit boards, torque test benches for testing motors, and motorized test stands for assessing the functionality of hydraulic systems. Sensors are increasingly integrated into test benches to monitor and analyze data during testing. The advent of Industry 4.0 principles, such as IoT and autonomous systems, has led to the development of advanced test benches. These IoT-enabled test benches collect and analyze data in real-time, enabling predictive maintenance, remote monitoring, and improved operational efficiency.

- Moreover, they gather data on various parameters, such as torque, force, and combustion, during testing, allowing manufacturers to identify anomalies and make informed decisions. Connected cars, self-driving cars, and other related industries rely on test benches to ensure quality and adherence to regulations. Quality standards and safety regulations require rigorous testing of components and systems, including turbines, hydraulic hoses, safety valves, and other critical components. Test benches provide the necessary stimuli and simulators to test these components under various conditions. Test benches are equipped with various supporting equipment, such as oscilloscopes, multimeters, soldering irons, and wire cutters, to facilitate quick testing and maintenance.

What challenges does Test Bench Industry face during the growth?

High cost of developing and maintaining advanced test benches is a key challenge affecting the industry growth.

- The market encompasses the manufacturing sector's demand for supporting equipment used in testing circuit boards, sensors, and other related industries' hardware. This market includes the production of torque test benches and motorized test stands for autonomous, self-driving, and connected cars, as well as electronics manufacturing. The hardware segment requires advanced testing solutions to meet quality standards during mass production. Test bench systems' development and maintenance involve a substantial investment in research and development. Engineers, designers, and technical specialists with specialized knowledge are required to create the necessary hardware, software, and automation components. Furthermore, the procurement of sensors, instruments, and measurement equipment for these advanced test benches can be costly, necessitating considerable capital expenditure.

- Moreover, the iterative process of refining test bench design and functionality can add to development time and costs. Manufacturers strive to optimize test bench performance and capabilities, ensuring the accuracy and reliability of their products. Quality regulations mandate rigorous testing, including testing samples and parameters under various stimuli, such as combustion, force, torque, and safety valves. Test benches' complexity necessitates the use of specialized equipment like oscilloscopes, multimeters, soldering irons, wire cutters, and quick testing machines for sensor testing. Turbines, hydraulic hoses, and safety valves are also essential components for some test benches. The high cost of developing and maintaining these advanced test benches may hinder market growth.

Exclusive Customer Landscape

The test bench market forecasting report includes the adoption lifecycle of the market, covering from the innovator's stage to the laggard's stage. It focuses on adoption rates in different regions based on penetration. Furthermore, the market report also includes key purchase criteria and drivers of price sensitivity to help companies evaluate and develop their market growth analysis strategies.

Customer Landscape

Key Companies & Market Insights

Companies are implementing various strategies, such as strategic alliances, market forecast, partnerships, mergers and acquisitions, geographical expansion, and product/service launches, to enhance their presence in the industry.

The test bench industry research and growth report includes detailed analyses of the competitive landscape of the market and information about key companies, including:

- AiSoar Hydraulic

- EFCO mechanical engineering GmbH

- Eiffage

- Guangzhou GENY Electric Co. Ltd.

- Ingersoll Rand Inc.

- JM Test Systems LLC

- Kanwal Enterprises

- Merchant Hydraulic

- Micro Epsilon Messtechnik GmbH and Co. KG

- Nagman Instruments and Electronics Pvt. Ltd.

- Nidec Corp.

- Ningbo Water Meter Group Co. Ltd.

- NSM Solutions

- POMA SYSTEMS GMBH

- Precocity Automation Systems

- Primon Automazioni Srl

- Robert Bosch GmbH

- Stephen Balaram Engineering Pvt. Ltd.

- Walter Stauffenberg GmbH and Co. KG

- ZF Friedrichshafen AG

Qualitative and quantitative analysis of companies has been conducted to help clients understand the wider business environment as well as the strengths and weaknesses of key industry players. Data is qualitatively analyzed to categorize companies as pure play, category-focused, industry-focused, and diversified; it is quantitatively analyzed to categorize companies as dominant, leading, strong, tentative, and weak.

Research Analyst Overview

The market plays a crucial role in the electronics industry, particularly in the manufacturing sector. This market encompasses a wide range of equipment used to test various components and systems, including circuit boards, sensors, and hardware segments. The primary objective of these test benches is to ensure the quality and reliability of products before they are released to the market. Test benches come in various forms, such as torque test benches and motorized test stands. These advanced testing solutions are essential in industries where precise measurements and accurate results are necessary, such as in the development of autonomous cars, self-driving cars, and connected cars.

In addition, the electronics industry relies heavily on these testing solutions to meet the increasing demand for advanced technologies and stringent quality standards. The supporting equipment market, which includes test benches, is a critical component of the manufacturing process. These solutions enable manufacturers to test samples efficiently and effectively, ensuring that their products meet the required quality regulations. Testing personnel use a range of parameters to evaluate the performance of components and systems, including force, torque, and various stimuli. Quality regulations are a significant driver for the market. As mass production increases, the need for reliable testing solutions becomes even more crucial.

Moreover, test benches help manufacturers maintain consistency in their production processes and ensure that their products meet the necessary safety and performance standards. The market is not limited to the electronics industry alone. It also extends to industries such as turbines, hydraulic hoses, safety valves, and combustion engines. In these industries, test benches are used to simulate various conditions and evaluate the performance of components under different stresses and stimuli. The use of test benches is not limited to manual lab bench testing. Advanced technologies, such as simulators, have made it possible to perform tests in a more automated and efficient manner.

In addition, Oscilloscopes, multimeters, soldering irons, and wire cutters are just a few examples of the various testing machines used in the industry. Therefore, the market plays a vital role in the electronics industry and other related industries. It enables manufacturers to ensure the quality and reliability of their products by providing precise and accurate testing solutions. The market is continually evolving, with advancements in technology leading to more efficient and automated testing solutions. As the demand for advanced technologies and stringent quality standards continues to grow, the market is poised for significant growth.

|

Test Bench Market Scope |

|

|

Report Coverage |

Details |

|

Page number |

159 |

|

Base year |

2023 |

|

Historic period |

2018-2022 |

|

Forecast period |

2024-2028 |

|

Growth momentum & CAGR |

Accelerate at a CAGR of 4.36% |

|

Market growth 2024-2028 |

USD 327.7 million |

|

Market structure |

Fragmented |

|

YoY growth 2023-2024(%) |

4.11 |

|

Key countries |

China, US, Germany, Japan, and UK |

|

Competitive landscape |

Leading Companies, Market Positioning of Companies, Competitive Strategies, and Industry Risks |

What are the Key Data Covered in this Market Research and Growth Report?

- CAGR of the Test Bench industry during the forecast period

- Detailed information on factors that will drive the market growth and forecasting between 2024 and 2028

- Precise estimation of the size of the market and its contribution of the industry in focus to the parent market

- Accurate predictions about upcoming market growth and trends and changes in consumer behaviour

- Growth of the market across APAC, Europe, North America, Middle East and Africa, and South America

- Thorough analysis of the market's competitive landscape and detailed information about companies

- Comprehensive analysis of factors that will challenge the growth of industry companies

We can help! Our analysts can customize this market research report to meet your requirements. Get in touch