Specialty Pulp And Paper Chemicals Market Size 2025-2029

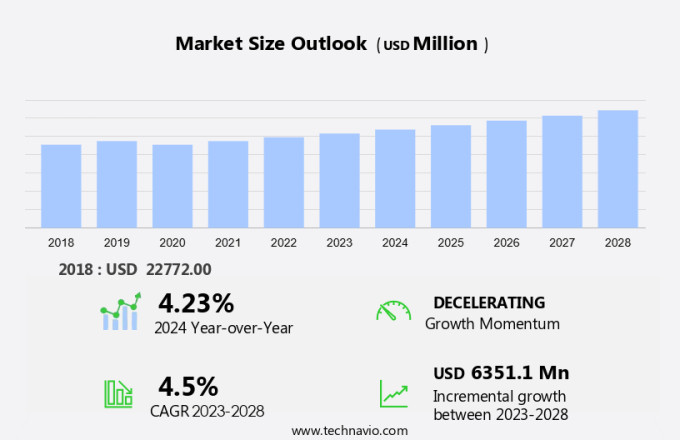

The specialty pulp and paper chemicals market size is forecast to increase by USD 6.88 billion, at a CAGR of 4.7% between 2024 and 2029.

- The market is driven by the increasing demand for specialty papers, particularly in sectors such as packaging, printing, and writing. This trend is fueled by advancements in technology that enable the production of high-performance and sustainable specialty papers. However, the market faces challenges due to the lack of availability of raw materials and the volatility of raw material prices. These factors can significantly impact the profitability of manufacturers and may necessitate strategic sourcing and supply chain management. To capitalize on market opportunities, companies must focus on innovation and efficiency in their production processes, while also implementing risk management strategies to mitigate the impact of raw material price fluctuations.

- Effective collaboration with suppliers and exploration of alternative raw materials can also help mitigate these challenges and ensure long-term competitiveness in the market.

What will be the Size of the Specialty Pulp And Paper Chemicals Market during the forecast period?

Explore in-depth regional segment analysis with market size data - historical 2019-2023 and forecasts 2025-2029 - in the full report.

Request Free Sample

The pulp and paper chemicals market is characterized by continuous evolution and dynamic market activities. Fiber modification through the manipulation of fiber length, ph control, and fiber morphology are essential aspects of wet-end chemistry in pulp and paper production. Mechanical pulp and chemical pulp each offer unique advantages, with mechanical pulp delivering high burst strength and chemical pulp providing energy efficiency and process optimization. In the realm of specialty pulp, green chemistry and slime control are paramount. Green chemistry focuses on reducing the environmental impact of pulp and paper production, while slime control ensures efficient production by preventing the buildup of unwanted materials in the pulp.

The printing industry relies on a variety of pulp mill chemicals, including sizing agents and deinking chemicals, to produce high-performance papers. Dissolving pulp, a critical component in the production of viscose and other cellulosic fibers, is another essential segment. Functional papers, such as tissue paper and packaging materials, require specialized chemicals like drainage aids and surface finishing agents to enhance their properties. Recycled fiber and pulp refining are also significant areas of focus, with advancements in fiber yield and process optimization driving growth. Raw material sourcing, quality control, and supply chain management are ongoing concerns for pulp and paper manufacturers.

Environmental compliance and energy efficiency are increasingly important factors in the industry, with a growing emphasis on sustainability and circular economy principles. Papermaking additives, such as retention aids and ash content control agents, play a crucial role in optimizing paper production. Wood pulp, industrial paper, and paper coating applications also benefit from these specialized chemicals. Technical support and innovation are key drivers in the pulp and paper chemicals market, with ongoing research and development efforts aimed at improving product performance and reducing environmental impact. The market is expected to remain dynamic, with new applications and technologies continually emerging.

How is this Specialty Pulp And Paper Chemicals Industry segmented?

The specialty pulp and paper chemicals industry research report provides comprehensive data (region-wise segment analysis), with forecasts and estimates in "USD billion" for the period 2025-2029, as well as historical data from 2019-2023 for the following segments.

- Type

- Functional chemicals

- Bleaching chemicals

- Process chemicals

- Others

- Application

- Printing and writing

- Packaging

- Tissue and hygiene

- Others

- Form Factor

- Liquid

- Powder

- Granules

- End-user

- Paper mills

- Recycled paper processing

- Specialty paper manufacturers

- Geography

- North America

- US

- Canada

- Europe

- France

- Germany

- Italy

- UK

- APAC

- China

- India

- Japan

- South Korea

- Rest of World (ROW)

- North America

By Type Insights

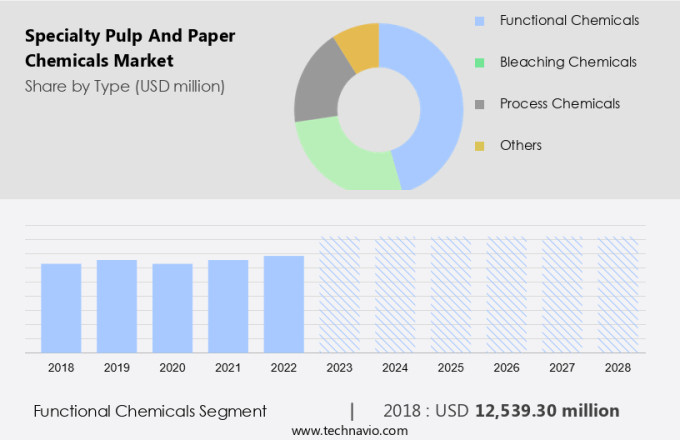

The functional chemicals segment is estimated to witness significant growth during the forecast period.

The market encompasses a range of functional chemicals used in the production of paper for various industries. These include cellulosic specialties, chelates, ethylene amines, metal alkyls, micronutrients, organic peroxides, polysulfides, re-dispersible powder polymers, salt specialties, sulfur products, dyes, pigments, and coating chemicals. Incorporated in the manufacturing process, these chemicals enhance paper properties such as fiber strength, tear strength, moisture content, and fiber length. Corrugated cardboard, a significant end-use industry, relies on retention aids, surface sizing, and wet-end chemistry for improved product quality. Research and development in this sector continues to focus on energy efficiency, environmental compliance, and the use of bio-based chemicals.

Paper mills prioritize process optimization and supply chain efficiency, while specialty pulp and papermaking additives contribute to high-performance papers. Functional papers, such as functional coatings and tear-resistant papers, require specialized chemicals for enhanced fiber morphology and burst strength. The printing industry demands deinking chemicals and sizing agents for efficient paper recycling. Pulp refining and papermaking processes utilize pulp bleaching and chemical recovery for optimal production capacity. The market's growth is driven by the increasing demand for functional chemicals in various applications, including printing and writing, packaging, and industrial uses. The integration of green chemistry principles and slime control measures further boosts market potential.

Despite challenges in raw material sourcing and ash content, the industry remains committed to maintaining fiber yield and paper strength while ensuring product development and quality control.

The Functional chemicals segment was valued at USD 13.07 billion in 2019 and showed a gradual increase during the forecast period.

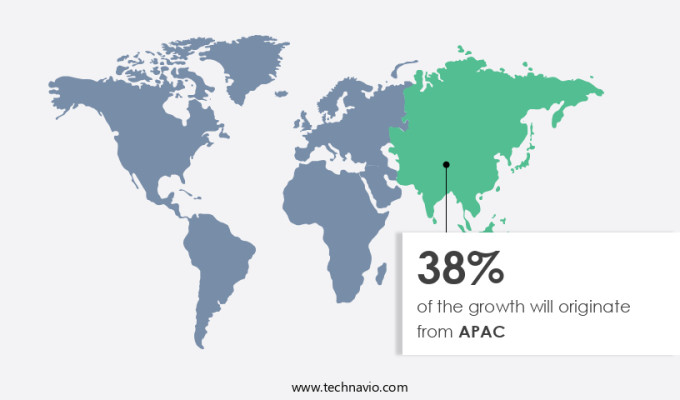

Regional Analysis

APAC is estimated to contribute 39% to the growth of the global market during the forecast period.Technavio’s analysts have elaborately explained the regional trends and drivers that shape the market during the forecast period.

The market in developing countries, including India, China, Malaysia, and Indonesia, is experiencing significant growth. This expansion is driven by several factors, such as low labor costs, affordable infrastructure, and abundant raw materials in these regions. The emergence of e-commerce companies creating demand for packaging papers is another contributing factor. China, being the world's largest paper-producing country, plays a pivotal role in this market's growth. Research and development efforts in specialty pulp and paper chemicals are focused on enhancing fiber strength, energy efficiency, and environmental compliance. Bio-based chemicals and green chemistry are gaining popularity due to their eco-friendly nature.

Optical brighteners, retention aids, surface sizing, and papermaking additives are some of the key product areas undergoing innovation. Raw material sourcing and pulp refining techniques are essential aspects of the market, with a focus on improving fiber yield and fiber length. Wet-end chemistry, including ph control and fiber morphology, plays a crucial role in papermaking. Paper mills are adopting process optimization and production capacity expansion to meet the increasing demand for specialty papers. Functional papers, high-performance papers, and recycled fiber are emerging trends in the market. Deinking chemicals, drainage aids, and tear strength enhancers are essential chemicals used in papermaking.

Effluent management and sizing agents are critical in maintaining paper quality and environmental compliance. The printing industry relies on pulp bleaching, paper coating, and surface finish to produce high-quality prints. Specialty pulp, including mechanical pulp and chemical pulp, is used to produce various paper grades. Burst strength and moisture content are essential properties that influence paper performance. In conclusion, the market in developing countries is growing due to favorable economic conditions and increasing demand for specialty papers. Innovation in papermaking additives, process optimization, and environmental compliance are key trends shaping the market.

Market Dynamics

Our researchers analyzed the data with 2024 as the base year, along with the key drivers, trends, and challenges. A holistic analysis of drivers will help companies refine their marketing strategies to gain a competitive advantage.

What are the key market drivers leading to the rise in the adoption of Specialty Pulp And Paper Chemicals Industry?

- The significant increase in demand for specialty paper serves as the primary market driver.

- The market is driven by the increasing demand for specialty papers in various industries and consumer applications. Countries like India, China, Brazil, Turkey, Poland, and Russia are significant contributors to market growth due to their high demand for specialty paper. In contrast, mature markets such as the US and Japan have a lower demand. Consumer preferences for decorative specialty paper and its increasing use in filtration, labeling, graphic arts, and food services sectors are major growth factors. Quick-service restaurants' demand for specialty paper products like cups, wraps, and bags is particularly noteworthy in the food services sector.

- Additionally, the application of specialty paper in folding cartons and flexible wraps is expanding market opportunities. Furthermore, the market is witnessing advancements in papermaking additives, pulp bleaching, paper coating, and effluent management. These improvements aim to enhance paper strength, surface finish, and chemical recovery, thereby increasing production capacity and reducing environmental impact. Technical support and chemical recovery processes are essential for manufacturers to remain competitive and meet evolving customer requirements.

What are the market trends shaping the Specialty Pulp And Paper Chemicals Industry?

- Advances in technology are currently shaping market trends. This significant progress in technology is a mandatory factor in today's professional business environment.

- The market is experiencing significant advancements, driving market growth in the coming years. Enzymes are increasingly being used in the manufacturing of specialty paper, contributing to the industry's development. These enzymes play a vital role in bleaching and de-inking processes, reducing chlorine bleach consumption and minimizing environmental impact. The application of enzymes in cellulose chemical reactions is expected to expand further. Moreover, the adoption of recycled pulp to decrease energy consumption and the implementation of technologies that optimize the processing of recycled pulp are notable trends in the market.

- Innovations in kraft pulping and mechanical pulping technologies are also advancing the industry. These developments aim to improve fiber modification, fiber length, ph control, fiber morphology, burst strength, slime control, and drainage aids, all essential factors in the production of high-quality specialty pulp and paper for various industries, including the printing industry and tissue paper production.

What challenges does the Specialty Pulp And Paper Chemicals Industry face during its growth?

- The scarcity of raw materials and their volatile pricing represent significant challenges to the industry's growth trajectory.

- The market faces significant challenges due to rising energy and freight costs, as well as raw material shortages. The availability of essential raw materials, including pulp, coating chemicals, and other specialty chemicals, poses a considerable hurdle for market participants. These issues directly impact profit margins, as companies often rely on a limited number of suppliers for their raw materials, particularly chemicals. For instance, Kemira, a key market player, has a restricted pool of global suppliers for its raw materials. Companies must navigate these challenges while continuing to invest in research and development to improve product offerings.

- In this context, innovation is crucial for enhancing fiber strength, tear strength, and surface sizing in corrugated cardboard production. Additionally, the shift towards bio-based chemicals and water treatment solutions is gaining momentum to reduce ash content and improve fiber properties in the wet-end chemistry. Overall, market participants must focus on raw material sourcing strategies and product development to remain competitive in the specialty pulp and paper chemicals industry.

Exclusive Customer Landscape

The specialty pulp and paper chemicals market forecasting report includes the adoption lifecycle of the market, covering from the innovator’s stage to the laggard’s stage. It focuses on adoption rates in different regions based on penetration. Furthermore, the specialty pulp and paper chemicals market report also includes key purchase criteria and drivers of price sensitivity to help companies evaluate and develop their market growth analysis strategies.

Customer Landscape

Key Companies & Market Insights

Companies are implementing various strategies, such as strategic alliances, specialty pulp and paper chemicals market forecast, partnerships, mergers and acquisitions, geographical expansion, and product/service launches, to enhance their presence in the industry.

Archroma Management - This company specializes in supplying advanced pulp and paper chemicals, enhancing the wet and dry strength of paper, tissue, and packaging products. Our offerings optimize paper performance, ensuring improved durability and consistency for various industries. These innovative solutions cater to the global market, boosting efficiency and sustainability in pulp and paper manufacturing processes.

The industry research and growth report includes detailed analyses of the competitive landscape of the market and information about key companies, including:

- Archroma Management

- Arkema

- Ashland Inc.

- BASF

- Buckman Laboratories lnternational Inc.

- Croda International Plc

- Ecolab Inc.

- ERCO Worldwide

- Evonik Industries AG

- Imerys S.A.

- INEOS Group Holdings S.A.

- Kemira Oyj

- Nouryon Chemicals Holding B.V.

- Novozymes AS

- Robert Specialty Paper Corp.

- Sappi Ltd.

- Solenis

- Solvay SA

- SNF Group

- The Dow Chemical Co.

Qualitative and quantitative analysis of companies has been conducted to help clients understand the wider business environment as well as the strengths and weaknesses of key industry players. Data is qualitatively analyzed to categorize companies as pure play, category-focused, industry-focused, and diversified; it is quantitatively analyzed to categorize companies as dominant, leading, strong, tentative, and weak.

Recent Development and News in Specialty Pulp And Paper Chemicals Market

- In January 2024, DuPont Nutrition & Biosciences launched a new line of specialty pulp and paper chemicals, named Avicel PHD, designed to improve the strength and viscosity of paper pulp, thereby enhancing the overall paper quality (DuPont Press Release).

- In March 2024, INEOS Styrolution, the world's leading styrenics supplier, and ABB, a leading technology provider, announced a strategic collaboration to develop and commercialize a new process technology for the production of styrene monomer (SM) from renewable feedstocks, which is expected to significantly reduce the carbon footprint of the specialty pulp and paper chemicals industry (INEOS Styrolution Press Release).

- In May 2025, Ahlstrom-Munksjö, a leading global specialty paper company, completed the acquisition of the fine paper business from Smurfit Kappa Group, expanding its presence in Europe and increasing its market share in the specialty pulp and paper chemicals sector (Ahlstrom-Munksjö Press Release).

- In July 2025, Sappi Limited, a major producer of specialty pulp and paper products, announced the commissioning of its new state-of-the-art, energy-efficient chemical recovery boiler at its Ngodwana Mill in South Africa, which is expected to reduce the mill's greenhouse gas emissions by approximately 100,000 tons per year (Sappi Press Release).

Research Analyst Overview

- The pulp and paper chemicals market is characterized by continuous innovation and advancements in technology. Forest management plays a crucial role in the production process, with log handling and wood harvesting ensuring a steady supply of raw materials. In the pulping stage, fiber extraction is facilitated through pulp digestion, while oxygen delignification and bleaching stages using chlorine dioxide and Elemental Chlorine-Free (ECF) or Totally Chlorine-Free (TCF) methods refine the pulp. Paper machines, including calendaring, coating, fourdrinier, and tissue, transform the pulp into paper. Advanced analytics, machine learning (ML), process simulation, and data analytics optimize production processes and improve product quality.

- Safety standards are paramount in pulp & paper machinery operations. Chemical recovery systems, such as white and black liquor, minimize waste and contribute to the circular economy. Paper testing and analysis ensure product consistency and adherence to industry standards. Sustainable forestry practices, carbon footprint reduction, and life cycle assessment are essential components of the industry's environmental impact mitigation strategies. Process control systems and cloud computing technologies streamline operations and enhance efficiency. Roll finishing and paper converting machinery complete the production process, preparing finished products for distribution. The market remains dynamic, with a focus on reducing environmental impact and improving process safety and efficiency.

Dive into Technavio’s robust research methodology, blending expert interviews, extensive data synthesis, and validated models for unparalleled Specialty Pulp And Paper Chemicals Market insights. See full methodology.

|

Market Scope |

|

|

Report Coverage |

Details |

|

Page number |

247 |

|

Base year |

2024 |

|

Historic period |

2019-2023 |

|

Forecast period |

2025-2029 |

|

Growth momentum & CAGR |

Accelerate at a CAGR of 4.7% |

|

Market growth 2025-2029 |

USD 6.88 billion |

|

Market structure |

Fragmented |

|

YoY growth 2024-2025(%) |

4.4 |

|

Key countries |

US, China, Japan, India, Canada, UK, Germany, South Korea, France, and Italy |

|

Competitive landscape |

Leading Companies, Market Positioning of Companies, Competitive Strategies, and Industry Risks |

What are the Key Data Covered in this Specialty Pulp And Paper Chemicals Market Research and Growth Report?

- CAGR of the Specialty Pulp And Paper Chemicals industry during the forecast period

- Detailed information on factors that will drive the growth and forecasting between 2025 and 2029

- Precise estimation of the size of the market and its contribution of the industry in focus to the parent market

- Accurate predictions about upcoming growth and trends and changes in consumer behaviour

- Growth of the market across APAC, North America, Europe, South America, and Middle East and Africa

- Thorough analysis of the market’s competitive landscape and detailed information about companies

- Comprehensive analysis of factors that will challenge the specialty pulp and paper chemicals market growth of industry companies

We can help! Our analysts can customize this specialty pulp and paper chemicals market research report to meet your requirements.