Bending Machine Market Size 2025-2029

The bending machine market size is forecast to increase by USD 2.48 billion at a CAGR of 5.2% between 2024 and 2029.

- The market is poised for significant growth, driven by the expanding machine tools industry and the increasing integration of robots with bending systems. This fusion of technologies enhances production efficiency and flexibility, catering to the evolving demands of various industries, particularly automotive and construction. However, the market encounters challenges that necessitate careful navigation. Regulatory hurdles impact adoption, as stringent safety regulations necessitate rigorous compliance, adding to the cost of manufacturing. Furthermore, deformation in metals due to speed variations can adversely affect the precision and quality of bending processes.

- Addressing these challenges through technological innovations and strategic partnerships will be crucial for market participants to capitalize on the lucrative opportunities presented by this dynamic market. Companies seeking to succeed must focus on delivering high-performance, cost-effective bending solutions while ensuring regulatory compliance and addressing metal deformation issues.

What will be the Size of the Bending Machine Market during the forecast period?

- In the industrial sector, the market is experiencing significant activity and trends. Financial setbacks in vehicle production have led to a focus on efficient bending procedures and automation to reduce cycle times and lower power consumption. The market encompasses various types of bending machines, including pipe bending machines and tube bending equipment, which are essential for infrastructure development and metal fabrication. Complex bending applications, such as cold forming intricate shapes, require high levels of bending expertise and precision. Bending software and simulation tools enable the design of customized bending processes, ensuring consistent outcomes and reducing the need for manual intervention.

- The future of bending machines lies in advanced technologies like CNC and induction bending, which offer increased technical proficiency and the ability to create visually appealing, high-quality products. Despite the benefits, acquisition cost and maintenance expenses are key considerations. Bending machine safety and product quality are paramount, with clamping cylinders and cleaner fuels essential for minimizing environmental footprint. The market caters to various metal bending applications, including exhaust systems and automotive design, and offers metal bending services to meet diverse industry needs. In the manufacturing landscape, the focus is on reducing production schedules and increasing accuracy, with bending machine design playing a crucial role in achieving these goals.

- The market's future promises to be an exciting one, with continued advancements in technology and the drive for personalized, high-quality products.

How is this Bending Machine Industry segmented?

The bending machine industry research report provides comprehensive data (region-wise segment analysis), with forecasts and estimates in "USD million" for the period 2025-2029, as well as historical data from 2019-2023 for the following segments.

- Application

- Automotive

- General machinery

- Transport machinery

- Precision engineering

- Building and construction

- Technology

- Hydraulic

- Mechanical

- Electric

- Pneumatic

- Type

- Automatic

- Semi-automatic

- Manual

- Capacity

- Heavy duty

- Medium duty

- Light duty

- Geography

- North America

- US

- Europe

- Germany

- Italy

- Russia

- UK

- APAC

- China

- India

- Japan

- South Korea

- South America

- Brazil

- Rest of World (ROW)

- North America

By Application Insights

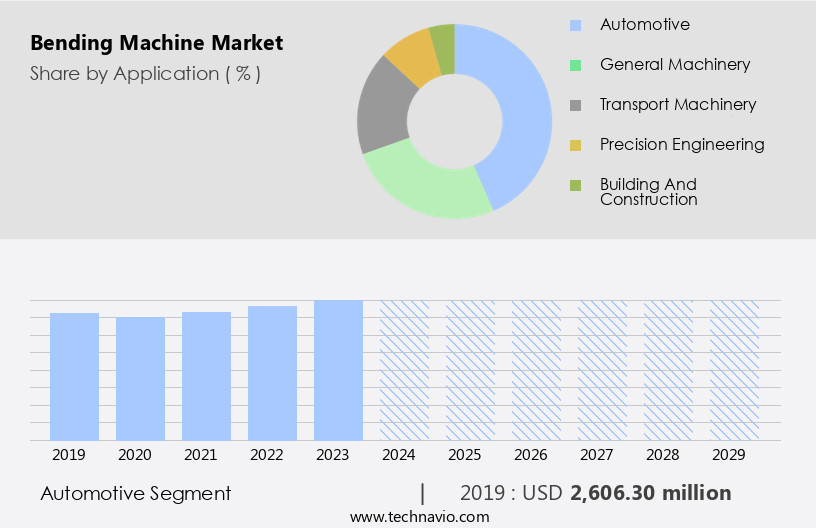

The automotive segment is estimated to witness significant growth during the forecast period.

Bending machines play a crucial role in various industries, particularly in automotive manufacturing, where tube bending and sheet metal bending applications are prevalent. These machines ensure consistency and accuracy in production processes, reducing operational costs. Traditional bending machines struggle with long tubing lines, requiring human assistance to prevent whipping during the bending process. This issue is addressed through the adoption of computerized numerical control (CNC) dual-head bending machines, which automate the bending process and eliminate the need for manual support. Bending machine design continues to evolve, incorporating advanced technologies such as robotics integration, CNC systems, and bending simulation.

Customized designs cater to specific industries and applications, including induction bending machines for high-volume bending and construction bending machines for heavy workpieces. Precision bending is essential for industries like aerospace, where metal forming technology requires exacting standards. Bending machine manufacturers focus on enhancing machine efficiency, safety, and cost-effectiveness. Robotic bending machines, for instance, offer increased precision and flexibility, while bar bending machines cater to specific metal bending applications. Bending machine maintenance and calibration are essential for optimal performance and longevity. Bending software and automation solutions streamline the manufacturing process, enabling manufacturing process optimization and real-time bending simulation.

Bending machine suppliers provide customized bending services and solutions, catering to various industries and applications. Bending machine cost remains a significant consideration, with ongoing research and development aimed at reducing acquisition costs and improving bending machine benefit. In summary, the bending machine industry continues to innovate, with a focus on automation, precision, and cost-effectiveness. From automotive manufacturing to aerospace and construction, bending machines play a vital role in metal fabrication processes, enabling industries to maintain high-quality standards and operational efficiency.

The Automotive segment was valued at USD 2.61 billion in 2019 and showed a gradual increase during the forecast period.

Regional Analysis

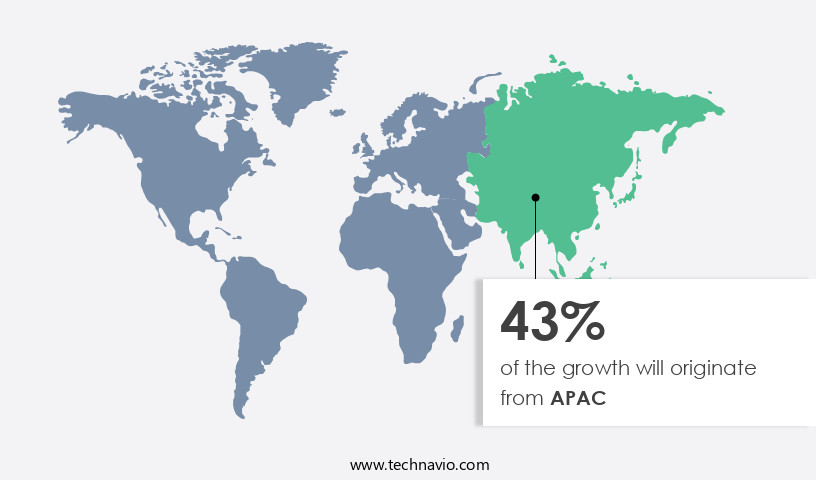

APAC is estimated to contribute 43% to the growth of the global market during the forecast period.Technavio’s analysts have elaborately explained the regional trends and drivers that shape the market during the forecast period.

The market in APAC is experiencing significant growth due to increased investments in manufacturing, construction, and transport sectors. The automotive industry's expansion also contributes substantially to the market share. China, Japan, South Korea, and Taiwan are major contributors to the APAC the market's dominance in the global market. The region's favorable business landscape, efficient administrative setup, attractive foreign policies, and low-cost, skilled labor make it an ideal location for bending machine manufacturers. Advancements in bending technology, such as automation, robotics integration, CNC systems, and simulation software, are driving market trends. Customized designs, precision bending, and high-volume bending are increasingly popular in various metal bending applications, including pipe bending, tube bending, sheet metal bending, and bar bending.

Bending machine manufacturers focus on improving machine precision, safety, and efficiency to meet evolving customer requirements. Metal bending services and metalworking industries are also adopting advanced bending techniques and technologies to optimize manufacturing processes. Challenges such as ensuring bending quality, die design, and machine calibration are addressed through ongoing research and development efforts. The market's future growth is expected to be driven by increasing demand for customized bending solutions, metal fabrication, and aerospace bending machines. Bending machine manufacturers are investing in R&D to create innovative designs and improve machine performance, efficiency, and cost-effectiveness. The market's competitive landscape includes various players, from large multinational corporations to small and medium-sized enterprises.

As the market continues to evolve, it will be essential for manufacturers to stay updated on the latest trends and technologies to remain competitive.

Market Dynamics

Our researchers analyzed the data with 2024 as the base year, along with the key drivers, trends, and challenges. A holistic analysis of drivers will help companies refine their marketing strategies to gain a competitive advantage.

What are the Bending Machine market drivers leading to the rise in the adoption of Industry?

- The global machine tools industry's growth serves as the primary catalyst for market expansion.

- The market is experiencing significant growth due to the expanding manufacturing sectors, particularly in developing countries. Driven by outsourcing, the proliferation of job shops, and increasing production in the automotive industry, the demand for bending machines is increasing. Furthermore, the shift towards electric vehicles and renewable energy projects, as well as the growth in air traffic, are creating new opportunities for bending machine manufacturers. Advancements in technology, such as automation and optimization, are also enhancing the efficiency and precision of bending processes.

- These trends are fueling the growth of the market, which serves various industries, including semiconductors, heavy machinery, and robotics. Bending machine cost and maintenance are important considerations for businesses, and ongoing research into metal bending techniques and tools is essential to meet the evolving demands of the market.

What are the Bending Machine market trends shaping the Industry?

- The integration of robots into bending systems is a current market trend, signifying a significant advancement in manufacturing technology. This fusion of automation and bending processes enhances efficiency, precision, and productivity.

- The market is experiencing significant growth due to the increasing adoption of robots in sheet metal fabrication and industrial automation. Robots offer advantages such as increased efficiency, output, and decreased costs, making them an attractive option for customized bending solutions in various industries, including aerospace. The high initial cost of robotic hardware and software has been a major barrier to entry, but technological advancements are driving down prices, making them more accessible. New-generation robots are highly versatile and can handle complex bending designs and heavy workpieces, including free-form bending, semi-automatic bending, and bending with specific radii.

- As the metalworking industry continues to evolve, bending machine suppliers are focusing on developing advanced bending solutions to meet the growing demand for customized metal fabrication.

How does Bending Machine market faces challenges face during its growth?

- The variation in metal deformation, which poses a significant challenge to the industry, is a critical factor impeding its growth.

- The precision bending market faces significant challenges due to metal deformations caused by variations in bending speed, particularly in tube bending. Multiple bending processes in tube manufacturing accumulate metal weight, making it harder to bend at full machine speed without deforming the tubes. This issue is more prevalent in long tube bending projects with multiple bends. Even a small deformation in the last bend can result in wasted metal or the need for additional cutting and welding, incurring extra costs and effort.

- Maintaining a moderate and steady bending speed is crucial to prevent such deformations and ensure the efficiency and quality of the bending process.

Exclusive Customer Landscape

The bending machine market forecasting report includes the adoption lifecycle of the market, covering from the innovator’s stage to the laggard’s stage. It focuses on adoption rates in different regions based on penetration. Furthermore, the bending machine market report also includes key purchase criteria and drivers of price sensitivity to help companies evaluate and develop their market growth analysis strategies.

Customer Landscape

Key Companies & Market Insights

Companies are implementing various strategies, such as strategic alliances, bending machine market forecast, partnerships, mergers and acquisitions, geographical expansion, and product/service launches, to enhance their presence in the industry.

Amada Co. Ltd. - The company showcases a range of advanced bending machines, including the HG Series, which boasts a robust high rigidity frame and a novel hybrid system for enhanced processing speed and superior quality. Another offering is the HG1003ATC, an innovative hybrid press brake featuring the latest automated tool change technology. These machines embody our commitment to delivering cutting-edge solutions for metal fabrication applications.

The industry research and growth report includes detailed analyses of the competitive landscape of the market and information about key companies, including:

- Amada Co. Ltd.

- AMOB

- BLM S.P.A.

- Bystronic Laser AG

- DANOBAT GROUP S. Coop.

- Dr Hochstrate Maschinenbau

- EUROMAC Spa

- Haco NV

- HAEUSLER AG Duggingen

- Inductaflex Ltd.

- LVD Co. nv

- Murata Machinery Ltd.

- Numalliance

- Promau S.r.l.

- SafanDarley BV

- Schnell Spa

- Schwarze Robitec GmbH

- Stierli Bieger AG

- Transfluid Maschinenbau GmbH

- TRUMPF SE Co. KG

Qualitative and quantitative analysis of companies has been conducted to help clients understand the wider business environment as well as the strengths and weaknesses of key industry players. Data is qualitatively analyzed to categorize companies as pure play, category-focused, industry-focused, and diversified; it is quantitatively analyzed to categorize companies as dominant, leading, strong, tentative, and weak.

Recent Development and News in Bending Machine Market

- In February 2024, Schmidt Bending Technologies, a leading bending machine manufacturer, introduced its innovative CNC Press Brake with a servo-driven backgauge, enhancing precision and productivity for the automotive industry (Schmidt Bending Technologies press release). In May 2025, Danobatgroup and Trumpf, two major players in the market, announced a strategic partnership to expand their global presence and offer integrated solutions to customers (Danobatgroup press release). In October 2024, ESAB, a leading manufacturer of welding and cutting equipment, acquired a significant stake in Cincinnati Incorporated, a prominent bending machine company, to strengthen its product portfolio and market position (ESAB press release). In January 2025, the European Union passed new regulations on the safety of machinery, including bending machines, requiring stricter safety measures and regular inspections to protect workers (European Parliament and Council of the European Union press release).

Research Analyst Overview

Navigating the Dynamic Landscape of Bending Machines: Precision, Automation, and Expertise Shaping the Future the market continues to evolve, driven by advancements in technology, increasing demand for efficiency, and the need for higher precision in metal bending applications. This dynamic landscape is shaped by several key trends. Bending Expertise and Automation: The integration of automation in bending machines is a significant trend, enabling manufacturers to streamline processes, reduce labor costs, and improve overall productivity. Automated bending machines, such as robotic and CNC systems, offer increased flexibility and the ability to handle complex bending tasks. However, the expertise of operators remains crucial in ensuring optimal bending results.

Bending Machine Design and Precision: The demand for higher precision in metal bending applications is driving advancements in bending machine design. Customized designs, such as those for automotive and aerospace industries, require precise bending capabilities. Advanced technologies like induction and CNC bending machines, as well as bending simulation software, help achieve the required level of precision. Bending Safety and Quality: Safety and quality are essential considerations in the bending machine industry. Manufacturers focus on developing machines that adhere to stringent safety standards while delivering high-quality bends. This includes features like bending machine calibration, bending machine maintenance, and bending machine safety systems.

Bending Software and Simulation: Software solutions, such as bending simulation and bending design tools, play a crucial role in optimizing the bending process. These tools help manufacturers design and test bending processes virtually, reducing the need for physical prototypes and improving overall efficiency. Bending Applications and Challenges: The bending machine industry caters to various applications, including industrial, construction, automotive, and aerospace. Each application presents unique challenges, such as the need for high-volume bending in industrial applications or free-form bending in aerospace. Addressing these challenges requires continuous innovation and collaboration between machine manufacturers and end-users. Bending Machine Cost and Manufacturing Process Optimization: Cost remains a critical factor in the market.

Manufacturers focus on reducing acquisition costs through economies of scale and technological advancements. Additionally, manufacturing process optimization and the use of bending tools and bending machine parts help improve overall efficiency and reduce costs. Bending Equipment and Manufacturers: The bending machine industry comprises various equipment types, including pipe bending machines, tube bending equipment, bar bending machines, and sheet metal bending machines. Leading manufacturers continue to innovate and expand their product offerings to cater to diverse customer needs. In conclusion, the market is characterized by continuous innovation and evolution. Trends such as automation, precision, safety, and software solutions are shaping the future of the industry.

Manufacturers must stay abreast of these trends and adapt to meet the evolving needs of their customers.

Dive into Technavio’s robust research methodology, blending expert interviews, extensive data synthesis, and validated models for unparalleled Bending Machine Market insights. See full methodology.

|

Market Scope |

|

|

Report Coverage |

Details |

|

Page number |

247 |

|

Base year |

2024 |

|

Historic period |

2019-2023 |

|

Forecast period |

2025-2029 |

|

Growth momentum & CAGR |

Accelerate at a CAGR of 5.2% |

|

Market growth 2025-2029 |

USD 2477.2 million |

|

Market structure |

Fragmented |

|

YoY growth 2024-2025(%) |

4.8 |

|

Key countries |

US, China, Germany, Japan, India, South Korea, Italy, UK, Russia, and Brazil |

|

Competitive landscape |

Leading Companies, Market Positioning of Companies, Competitive Strategies, and Industry Risks |

What are the Key Data Covered in this Bending Machine Market Research and Growth Report?

- CAGR of the Bending Machine industry during the forecast period

- Detailed information on factors that will drive the growth and forecasting between 2025 and 2029

- Precise estimation of the size of the market and its contribution of the industry in focus to the parent market

- Accurate predictions about upcoming growth and trends and changes in consumer behaviour

- Growth of the market across APAC, North America, Europe, Middle East and Africa, and South America

- Thorough analysis of the market’s competitive landscape and detailed information about companies

- Comprehensive analysis of factors that will challenge the bending machine market growth of industry companies

We can help! Our analysts can customize this bending machine market research report to meet your requirements.