Blow Molding Machinery Market Size 2024-2028

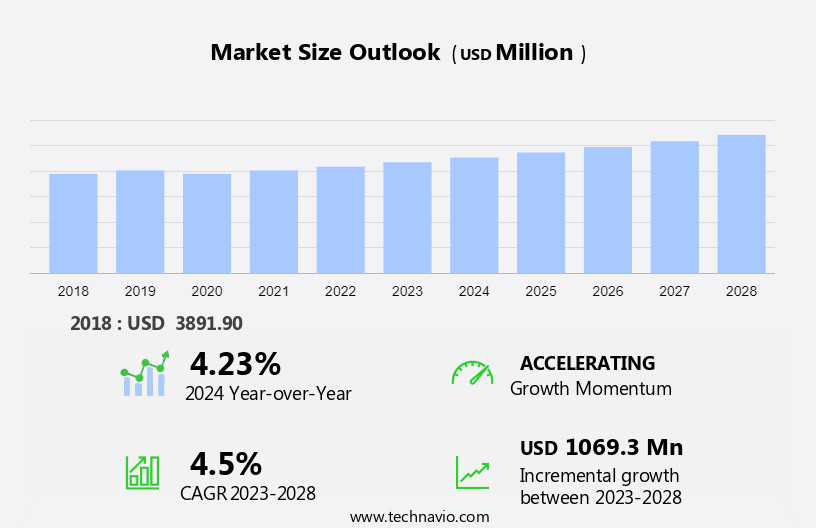

The blow molding machinery market size is forecast to increase by USD 1.07 billion at a CAGR of 4.5% between 2023 and 2028.

What will be the Size of the Blow Molding Machinery Market During the Forecast Period?

How is this Blow Molding Machinery Industry segmented and which is the largest segment?

The blow molding machinery industry research report provides comprehensive data (region-wise segment analysis), with forecasts and estimates in "USD million" for the period 2024-2028, as well as historical data from 2018-2022 for the following segments.

- End-user

- Food packaging

- Construction

- Others

- Geography

- North America

- US

- APAC

- China

- India

- Europe

- Germany

- UK

- South America

- Middle East and Africa

- North America

By End-user Insights

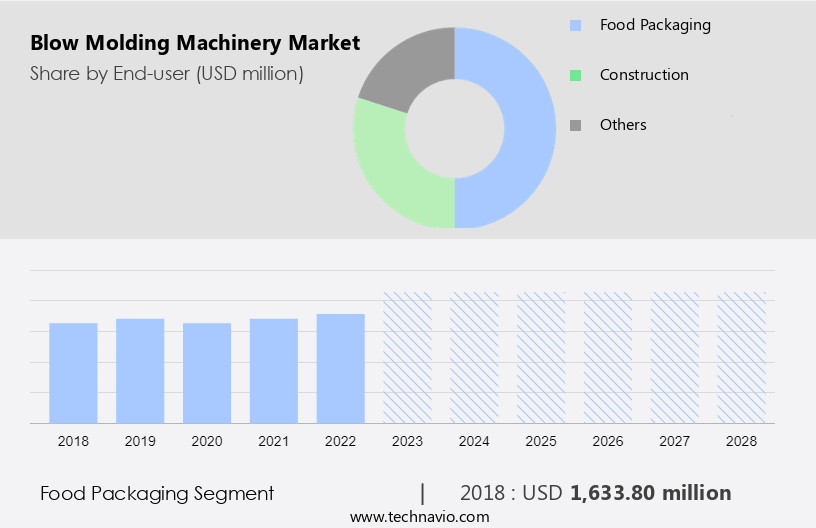

The food packaging segment is estimated to witness significant growth during the forecast period. The market is driven by the food and beverages industry, with significant growth expected In the food packaging segment during the forecast period. The demand for blow molding machinery arises from the need for reliable packaging solutions to distribute and protect food and beverage products. Blow molding machinery is essential for producing hollow plastic products, including plastic bottles, plastic tubes, and containers, which are widely used In the food and beverages industry. In addition, the pharmaceuticals industry also utilizes blow molding machinery for producing packaging components, such as plastic cans and jars. The use of advanced technologies, such as injection blow molding and extrusion blow molding, enables the production of high-quality, lightweight, and cost-effective packaging solutions.

The automotive and construction sectors also contribute to the market growth due to the demand for large-scale production of automotive parts and construction components, respectively. Energy-efficient and eco-friendly practices, such as the use of recycled materials and computer-based technologies, are increasing in popularity, further driving the market growth. The market for blow molding machinery is expected to continue expanding due to the increasing demand for innovative, sustainable, and cost-effective packaging solutions across various industries.

Get a glance at the market report of various segments Request Free Sample

The Food packaging segment was valued at USD 1.63 billion in 2018 and showed a gradual increase during the forecast period.

Regional Analysis

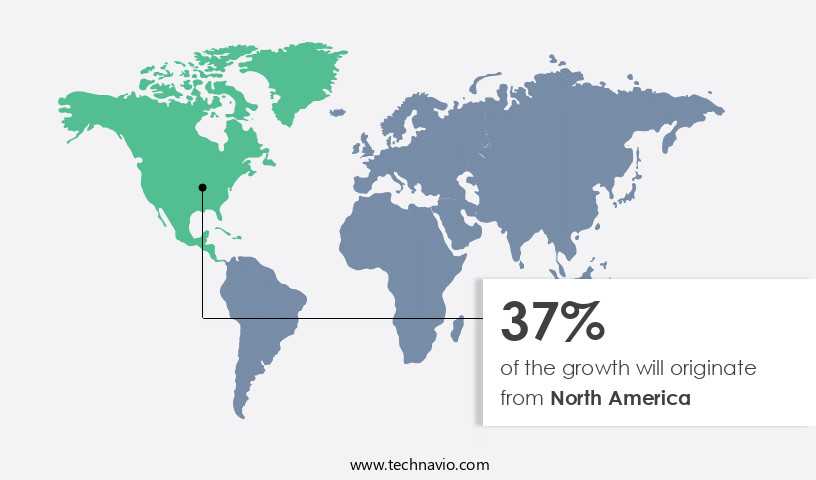

North America is estimated to contribute 37% to the growth of the global market during the forecast period. Technavio’s analysts have elaborately explained the regional trends and drivers that shape the market during the forecast period.

For more insights on the market size of various regions, Request Free Sample

The market in North America is experiencing significant growth, driven by the US, Mexico, and Canada. The US, as a leading manufacturer and consumer of blow molded plastic packaging solutions, saw high consumer expenditure on packaged goods in 2018. Furthermore, the increasing consumption of packaged beverages, particularly PET bottles, will continue to fuel demand In the region. North America's abundant shale gas production facilitates the derivation of plastic polymer resins such as HDPE, LDPE, and LLDPE. The Food & Beverages industry, including the Pharmaceuticals sector, is a major consumer of blow molded plastic components, including bottles, containers, and tubes. Blow molding technologies, such as injection blow molding and extrusion blow molding, are used to produce a wide range of products, from small plastic components to large-scale automotive parts.

Energy-efficient, computer-based technologies, and flexible packaging solutions are key trends In the market. The market caters to various industries, including the Automotive and Construction sectors, and offers customization options, flexibility, and high production efficiency. Sustainable practices, such as eco-friendly and recyclable packaging, are also gaining importance.

Market Dynamics

Our researchers analyzed the data with 2023 as the base year, along with the key drivers, trends, and challenges. A holistic analysis of drivers will help companies refine their marketing strategies to gain a competitive advantage.

What are the key market drivers leading to the rise In the adoption of Blow Molding Machinery Industry?

- Growth of e-commerce industry is the key driver of the market.The market is witnessing significant growth due to the increasing demand for hollow plastic products in various industries, particularly In the food & beverages and pharmaceuticals sectors. Hollow plastic products, including plastic bottles, tubes, containers, and jerry cans, are widely used for packaging food & beverages, such as water bottles, soft drink bottles, and household products like hand soaps and sanitizers. In the pharmaceuticals industry, blow molding machinery is used to produce packaging components for medical devices, toys, and other applications. The market is driven by factors such as the need for compactness, quality, strength, and weight in plastic components for transportation applications, automotive parts, and construction materials.

Advanced technologies, such as injection blow molding and extrusion blow molding, are used to produce complex shapes and product designs. Polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), polyethylene terephthalate (PET), and other polymers are commonly used in blow molding processes. The market is also witnessing the adoption of eco-friendly practices, such as recycled materials and sustainable packaging solutions, to reduce waste and promote energy efficiency. The market is further expected to grow due to the increasing demand for advanced control systems, energy-saving features, and automation in blow molding machinery. Flexible packaging, such as tri-layer technology and full electric systems, is also gaining popularity due to its cost-effectiveness and innovative packaging solutions.

In conclusion, the market is expected to grow significantly due to the increasing demand for plastic components in various industries, including food & beverages, pharmaceuticals, automotive, construction, and consumer goods. The market is driven by factors such as the need for compactness, quality, strength, and weight, as well as the adoption of advanced technologies and eco-friendly practices.

What are the market trends shaping the Blow Molding Machinery market?

- Development of advanced plastic machinery is the upcoming market trend.The market is witnessing significant growth due to the increasing demand for hollow plastic products in various industries. This market caters to the production of plastic bottles, tubes, containers, and other packaging components for the food & beverages industry, pharmaceuticals industry, and others. Compressed air is utilized In the blow molding process, which involves the use of a parison, or preform, that is blown into shape using heat and air pressure. Plastic materials such as Polyethylene (PE), Polypropylene (PP), Polyvinyl chloride (PVC), Polyethylene terephthalate (PET), and others are used In the production of these packaging solutions. The market offers a wide range of products, from small plastic items to large-scale production for automotive and construction sectors.

Advancements in technology have led to the development of energy-efficient, computer-based systems, and flexible packaging solutions. Innovative packaging designs, such as tri-layer technology and full electric systems, are gaining popularity In the market. Plastic manufacturers are focusing on sustainable practices, eco-friendly packaging, and recyclable packaging to cater to the growing demand for environmentally friendly solutions. The market also offers customization options, flexibility, and high production efficiency. Plastic tube manufacturing, mold design, and extrusion molding technology are some of the advanced techniques used In the production process. The market caters to various industries, including food & beverages, pharmaceuticals, consumer goods, automotive, construction, and others.

Plastic components are used in various applications, such as bottles, packaging materials, automotive parts, fuel tanks, air ducts, interior trims, electronics parts, plastic housings, cases, enclosures, construction parts, pipes, and tanks. Advanced control systems, energy-saving features, and automation are some of the key features of modern plastic machinery. The market offers cost-effective packaging solutions, brand differentiation, aesthetically pleasing packaging, and sustainable practices. Plastic waste management and recycling are also crucial aspects of the market. The market caters to various sectors, including personal care, household products, automotive, and industrial packaging. In conclusion, the market is a dynamic and innovative industry that caters to the production of various plastic products using advanced technology and sustainable practices.

The market offers a wide range of products and services, catering to various industries and applications. The focus on energy efficiency, automation, and sustainability is driving the growth of the market.

What challenges does the Blow Molding Machinery Industry face during its growth?

- Threat from refurbished machines is a key challenge affecting the industry growth.The market faces restraint due to the high cost of machinery, which limits small businesses from adopting this technology. The closure of industries In the US and Europe, driven by high labor costs and stringent pollution regulations, has led to an increased supply of second-hand blow molding machines in Asia Pacific countries like China and India. These machines are in demand due to the region's low-cost manufacturing environment. Blow molding machinery is used for producing hollow plastic products such as plastic bottles, plastic tubes, and containers for various industries, including food & beverages and pharmaceuticals. The market dynamics include factors such as compactness, quality, strength, and weight, which are crucial for industries like automotive and construction.

Injection blow molding and extrusion blow molding technologies are commonly used for producing plastic components in various shapes and sizes, using materials like PE, PP, PVC, PET, and PBT. The market offers innovative packaging solutions for various applications, including beverages, personal care, household products, automotive parts, and industrial packaging. Advanced control systems, energy-saving features, and automation are essential features of modern blow molding machinery. Sustainable practices, such as eco-friendly and recyclable packaging, are gaining popularity, with tri-layer technology and full electric systems being widely adopted. The market caters to diverse industries, including automotive, construction, packaging, and consumer goods, offering cost-effective packaging solutions and brand differentiation through aesthetically pleasing and innovative packaging designs.

The use of recycled materials and high-volume production capabilities further add to the market's appeal. The market's complexity lies In the production of various shapes and sizes, product strength, and customization options, making it a versatile solution for various industries.

Exclusive Customer Landscape

The blow molding machinery market forecasting report includes the adoption lifecycle of the market, covering from the innovator’s stage to the laggard’s stage. It focuses on adoption rates in different regions based on penetration. Furthermore, the blow molding machinery market report also includes key purchase criteria and drivers of price sensitivity to help companies evaluate and develop their market growth analysis strategies.

Customer Landscape

Key Companies & Market Insights

Companies are implementing various strategies, such as strategic alliances, blow molding machinery market forecast, partnerships, mergers and acquisitions, geographical expansion, and product/service launches, to enhance their presence In the industry.

BEKUM Maschinenfabriken GmbH - Blow Molding Machinery is a critical segment In the plastics industry, encompassing equipment such as Accumulator, Single Station, and Multi Cavity machines. These machines facilitate the production of hollow parts through the blowing action of air pressure applied to molten plastic material within a mold. Accumulator machines offer continuous production, while Single Station machines produce parts one at a time. Multi Cavity machines, on the other hand, manufacture multiple parts concurrently, enhancing efficiency. Blow Molding Machinery's versatility caters to various industries, including automotive, packaging, and consumer goods, among others. The technology's ability to produce complex shapes and sizes, along with its cost-effectiveness, continues to drive its adoption in numerous applications.

The industry research and growth report includes detailed analyses of the competitive landscape of the market and information about key companies, including:

- BEKUM Maschinenfabriken GmbH

- Blow Enterprises

- British Plastics Federation

- Chia Ming Machinery Co Ltd.

- Golfang Mfg. and Development Co. Ltd.

- Jagmohan Pla Mach Pvt. Ltd.

- Jiangsu Victor Machinery Co. Ltd

- Jomar Corp.

- Meccanoplastica Srl

- Nissei ASB Machine Co. Ltd.

- Parker plastic machinery Co. Ltd.

- Polymechplast Machines Ltd.

- Suma Plastic Machinery Co. Ltd.

- Sumitomo Heavy Industries Ltd.

- SuZhou Bestar Blow Molding Technology Co. Ltd.

- The Japan Steel Works Ltd.

- thyssenkrupp AG

- Universal Machinery and Services

- Zeel plast Machinery

Qualitative and quantitative analysis of companies has been conducted to help clients understand the wider business environment as well as the strengths and weaknesses of key industry players. Data is qualitatively analyzed to categorize companies as pure play, category-focused, industry-focused, and diversified; it is quantitatively analyzed to categorize companies as dominant, leading, strong, tentative, and weak.

Research Analyst Overview

The market encompasses a diverse range of equipment used to produce hollow plastic products for various industries. These products include containers for the food and beverages industry, such as water bottles and soft drink bottles, as well as jars and cans. The pharmaceuticals industry also utilizes blow molding machinery to produce packaging components, including bottles and containers for medicines. Blow molding processes, such as injection blow molding and extrusion blow molding, enable the production of high-quality, strong, and lightweight plastic products. The technology offers advantages in terms of compactness, energy efficiency, and the ability to produce complex shapes and sizes.

The market for blow molding machinery serves numerous sectors, including the automotive and construction industries. In the automotive sector, blow molded plastic components are used for fuel tanks, air ducts, interior trims, and other applications. In the construction sector, blow molded plastic pipes and tanks are employed for various building and infrastructure projects. Polyethylene (PE), polypropylene (PP), polyvinyl chloride (PVC), and polyethylene terephthalate (PET) are among the commonly used polymers in blow molding applications. The choice of polymer depends on the specific requirements of the application, such as product strength, weight, and flexibility. The packaging sector is a significant consumer of blow molding machinery.

Blow molded plastic containers offer advantages in terms of cost-effectiveness, brand differentiation, and sustainability. Innovative packaging solutions, such as tri-layer technology and full electric systems, are increasingly being adopted to meet evolving consumer demands. Flexible packaging, including plastic tubes and bags, are also produced using blow molding machinery. These products are used in various industries, including the personal care and household products industry, for items such as hand soaps, sanitizers, and cleaning products. The market for blow molding machinery is driven by factors such as the increasing demand for eco-friendly and recyclable packaging, as well as the need for advanced control systems and energy-saving features.

Automation and customization options are also key trends In the market. Blow molding machinery is used to produce a wide range of plastic products, from small containers and packaging components to large-scale automotive parts and industrial packaging. The market for blow molding machinery is diverse and dynamic, with ongoing innovation and advancements in technology driving growth and expansion.

|

Market Scope |

|

|

Report Coverage |

Details |

|

Page number |

146 |

|

Base year |

2023 |

|

Historic period |

2018-2022 |

|

Forecast period |

2024-2028 |

|

Growth momentum & CAGR |

Accelerate at a CAGR of 4.5% |

|

Market growth 2024-2028 |

USD 1069.3 million |

|

Market structure |

Fragmented |

|

YoY growth 2023-2024(%) |

4.23 |

|

Key countries |

US, China, Germany, India, and UK |

|

Competitive landscape |

Leading Companies, Market Positioning of Companies, Competitive Strategies, and Industry Risks |

What are the Key Data Covered in this Blow Molding Machinery Market Research and Growth Report?

- CAGR of the Blow Molding Machinery industry during the forecast period

- Detailed information on factors that will drive the growth and forecasting between 2024 and 2028

- Precise estimation of the size of the market and its contribution of the industry in focus to the parent market

- Accurate predictions about upcoming growth and trends and changes in consumer behaviour

- Growth of the market across North America, APAC, Europe, South America, and Middle East and Africa

- Thorough analysis of the market’s competitive landscape and detailed information about companies

- Comprehensive analysis of factors that will challenge the blow molding machinery market growth of industry companies

We can help! Our analysts can customize this blow molding machinery market research report to meet your requirements.