Cotton Ginning Machines Market Size 2025-2029

The cotton ginning machines market size is forecast to increase by USD 25.6 million at a CAGR of 3.3% between 2024 and 2029.

- The market is experiencing significant growth due to the increasing consumption of cotton and related products. Cotton is a versatile fiber widely used in various industries, including textiles, paper, and automotive, among others. Moreover, the storage of seed cotton in polythene wrappings has become increasingly popular, leading to an increased demand for efficient cotton ginning machines. However, the prevalence of manual cotton ginning practices in some regions poses a challenge to market growth. Key drivers of the market include the growing demand for cotton and the need for increased productivity and efficiency in cotton ginning processes.

- Automated cotton ginning machines offer several advantages, such as faster processing times, reduced labor costs, and improved product quality. Additionally, the adoption of advanced technologies, such as Internet of Things and Artificial Intelligence, in cotton ginning machines is expected to further boost market growth. Companies seeking to capitalize on these opportunities should focus on innovation and technology development to meet the evolving needs of the market. Furthermore, navigating regulatory requirements and addressing the challenges posed by manual ginning practices will be crucial for market success.

What will be the Size of the Cotton Ginning Machines Market during the forecast period?

- The market encompasses the production and sale of machinery used to extract cotton fibers from cotton bales in the cotton industry. Infrastructure development and mechanization have significantly impacted cotton ginning processes, leading to increased efficiency and productivity. Cotton farming, a crucial component of agricultural production, benefits from mechanized ginning methods such as roller ginning and saw gin technology. These advancements have increased the ginning percentage, enabling cotton growers to produce more cotton fibers per bale. Cotton ginning machinery includes single roller and double roller designs, with the former being more common in long cotton ginning processes.

- The integration of autonomous machines and cotton pressing technology has further streamlined production processes. Customer preferences for DNA traceability systems and cost-effective individual costs have driven the market's growth. The increasing urban population and demand for cotton materials have also contributed to the market's expansion. Overall, the market is expected to continue experiencing growth due to advancements in ginning technology and the ongoing demand for cotton fibers in various industries.

How is the Cotton Ginning Machines Industry segmented?

The industry research report provides comprehensive data (region-wise segment analysis), with forecasts and estimates in "USD million" for the period 2025-2029, as well as historical data from 2019-2023 for the following segments.

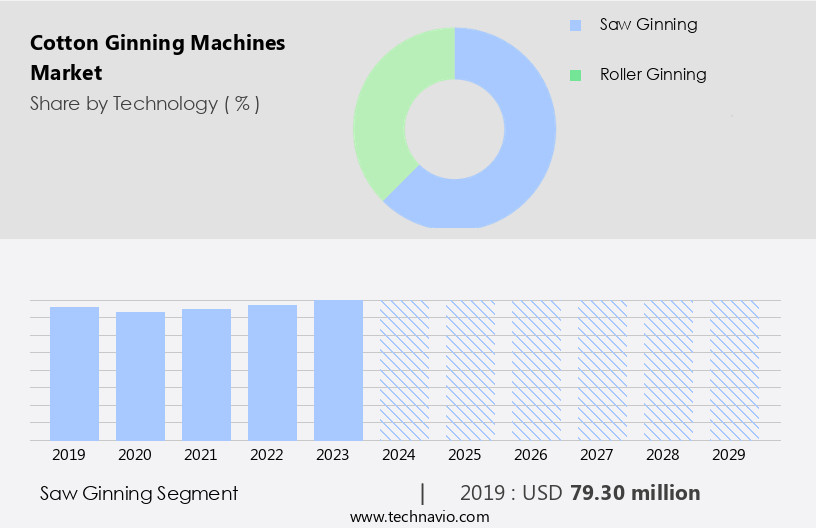

- Technology

- Saw ginning

- Roller ginning

- Type

- Manual

- Automatic

- Application

- Large-scale

- Medium-scale

- Small-scale

- Geography

- APAC

- Australia

- China

- India

- Japan

- South Korea

- North America

- US

- Canada

- Europe

- Germany

- UK

- South America

- Brazil

- Middle East and Africa

- APAC

By Technology Insights

The saw ginning segment is estimated to witness significant growth during the forecast period. Cotton ginning machines utilize fast-moving circular saws to process seed cotton, separating cotton fibers from seeds during the ginning process. The fibers pass through narrow metal ribs, which cause seeds and impurities to be ejected, while the lint is collected. Brush and air blast mechanisms facilitate the separation of lint from seed cotton. However, challenges persist, including the high maintenance costs due to the limited availability of parts and the need for a skilled technician to operate saw ginning machines. The cotton industry relies heavily on ginning technology to enhance production efficiency, improve cotton quality, and reduce costs associated with manual ginning.

Furthermore, innovations in cotton ginning automation, safety, and sustainability have significantly impacted the cotton ginning market. These advancements include fiber properties analysis, traceability, and fiber recycling, which have influenced textile trends and cotton fiber processing. Cotton ginning certification and standards ensure consistency in cotton quality, contributing to the overall success of the cotton industry. Price fluctuations, pests, and diseases pose challenges to cotton production, necessitating ongoing research and innovation in cotton breeding and genetics. The cotton market is driven by demand for cotton fabric, yarn, thread, and home textiles, with organic cotton gaining popularity due to sustainability concerns.

Get a glance at the market report of share of various segments Request Free Sample

The Saw ginning segment was valued at USD 79.30 million in 2019 and showed a gradual increase during the forecast period.

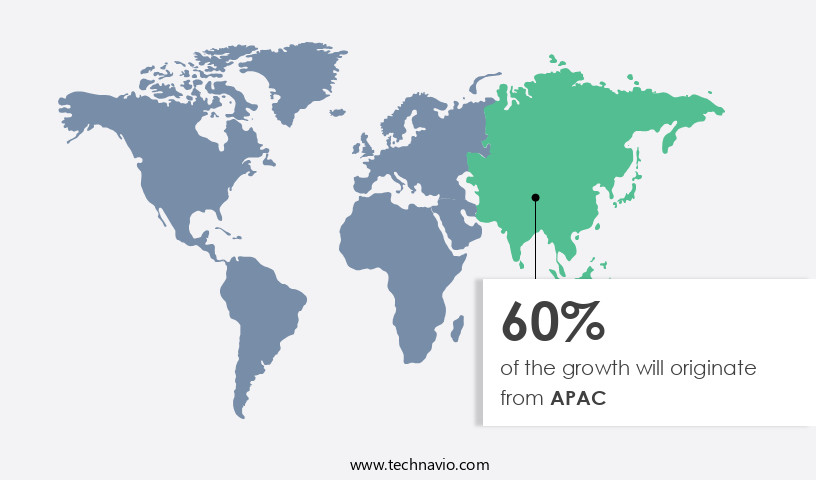

Regional Analysis

APAC is estimated to contribute 60% to the growth of the global market during the forecast period. Technavio's analysts have elaborately explained the regional trends and drivers that shape the market during the forecast period.

For more insights on the market size of various regions, Request Free Sample

The market is poised for growth, particularly in Asia Pacific (APAC) countries, with China and India leading the way due to their significant cotton production. India, as a major global cotton producer, will influence market trends in the region. The expanding applications of cotton in industries such as medical, packaging, and textile will further boost demand for cotton ginning machines. In China, the largest global cotton producer and importer, market players are investing in marketing efforts to encourage adoption. Cotton's versatility in various sectors, including cotton fabric, cotton yarn, cotton thread, cotton bedding, and cotton home textiles, drives market expansion.

Advancements in cotton technology, such as automation, safety, sustainability, and quality control, are key factors shaping the market. Cotton fiber properties, cotton fiber testing, cotton fiber processing, and cotton fiber recycling are essential aspects of the cotton ginning process. Price fluctuations, cotton pests, and diseases impact the cotton industry, necessitating innovation and efficiency in cotton ginning. Organic cotton and textile trends also influence market dynamics. The cotton ginning certification and standards ensure product quality and traceability, while cotton tagging technology and cotton breeding contribute to improved cotton production. The market's future growth is influenced by factors such as cotton production costs, cotton waste management, and cotton industry trends.

Market Dynamics

Our researchers analyzed the data with 2024 as the base year, along with the key drivers, trends, and challenges. A holistic analysis of drivers will help companies refine their marketing strategies to gain a competitive advantage.

What are the key market drivers leading to the rise In the adoption of Cotton Ginning Machines Industry?

- Increasing consumption of cotton and related products is the key driver of the market. The market is driven by the dominance of the textile industry and the resulting demand for cotton as a primary raw material. The expanding population and economic development fuel the need for clothing and textiles, leading to increased consumption of cotton. Cotton's natural qualities, such as breathability, comfort, and adaptability, make it a preferred choice for various products, including clothing, household textiles, and industrial items.

- Economic, cultural, and environmental factors all play a role in the growing consumption of cotton and related products. The textile industry's reliance on cotton as a raw material underpins the market's growth trajectory.

What are the market trends shaping the Cotton Ginning Machines Industry?

- Storage of seed cotton in polythene wrappings is the upcoming market trend. Seed cotton, a crucial component in cotton production, has historically been stored in gunny bags in several developing countries. Despite their affordability, these bags allow moisture to penetrate the seed cotton, necessitating additional ginning processes and negatively impacting its quality.

- In contrast, developed nations have adopted advanced cotton harvesters from renowned international companies like Case IH and Deere. These harvesters feature attachments that automate the bale-making process, enabling cotton to be stored in cylindrical or cuboidal shapes, covered with polyethylene films. The benefits of this innovation extend beyond convenient storage and transportation; the polythene film effectively prevents moisture intrusion, thereby maintaining the quality of the cotton bales.

What challenges does the Cotton Ginning Machines Industry face during its growth?

- Prevalence of manual cotton ginning practices is a key challenge affecting the industry's growth. Manual cotton ginning machines play a significant role in the cotton ginning process, particularly in smaller-scale operations or areas where labor is abundant and inexpensive. However, this method adds a higher level of labor intensity, which can impact overall efficiency and productivity. In contrast, automated cotton ginning machines offer faster processing speeds and increased efficiency, making them more suitable for large-scale operations.

- The slower processing speed of manual machines can hinder the ability to meet market demand during peak harvesting periods. While manual ginning may be sufficient for certain applications, the adoption of automated systems is a trend in the industry due to their ability to increase productivity and meet the demands of the market.

Exclusive Customer Landscape

The market forecasting report includes the adoption lifecycle of the market, covering the innovator's stage to the laggard's stage. It focuses on adoption rates in different regions based on penetration. Furthermore, the market report also includes key purchase criteria and drivers of price sensitivity to help companies evaluate and develop their market growth analysis strategies.

Customer Landscape

Key Companies & Market Insights

Companies are implementing various strategies, such as strategic alliances, market forecast, partnerships, mergers and acquisitions, geographical expansion, and product/service launches, to enhance their presence in the industry.

APPLE ELECTRONIKS - The company offers advanced cotton ginning technology, including the Roller Cotton Ginning Machine. I

The industry research and growth report includes detailed analyses of the competitive landscape of the market and information about key companies, including:

- APPLE ELECTRONIKS

- Bajaj Steel Industries Ltd.

- Balkan Cotton Gin Machinery Ltd.

- Bhagwati Engineering Works

- Cherokee Fabrication

- Deligent Ginning Machinery Pvt. Ltd.

- JADHAO GEARS PVT. LTD.

- Karunanand Hydro-Pneumatic Controls (p) Ltd.

- Lummus Corp.

- Mitsun Engineering

- NIPHA EXPORTS Pvt. Ltd.

- PRAMUKH STEEL INDUSTRIES

- Ramtex Ginning Automation

- Shandong Swan Cotton Industry Machinery Co. Ltd.

- SUMER MAKINA

Qualitative and quantitative analysis of companies has been conducted to help clients understand the wider business environment as well as the strengths and weaknesses of key industry players. Data is qualitatively analyzed to categorize companies as pure play, category-focused, industry-focused, and diversified; it is quantitatively analyzed to categorize companies as dominant, leading, strong, tentative, and weak.

Research Analyst Overview

The market encompasses the industry dedicated to the process of separating cottonseeds from cotton fibers. This essential step in cotton production has undergone significant advancements, driving efficiency, safety, and sustainability. Cotton farming techniques have evolved over the years, with an increasing focus on reducing production costs and minimizing waste. Manual ginning, a labor-intensive method, has largely been replaced by automated systems. These innovations have revolutionized the cotton ginning process, enabling the production of higher-quality cotton fibers. The cotton industry trends reflect the growing importance of technology in all aspects of cotton production and processing. Cotton technology advancements have led to improvements in cotton fiber properties, enabling the creation of superior cotton yarn and textiles.

Moreover, quality control measures have become more stringent, ensuring consistent fiber quality and meeting various certification standards. Cotton price fluctuations have a significant impact on the market. Price volatility can affect the profitability of the operations. To mitigate this risk, efficiency has become a critical focus, with innovations aimed at reducing energy consumption and minimizing downtime. Sustainability is a key consideration in the industry. The increasing demand for organic and sustainably produced cotton has led to the development of more environmentally-friendly ginning methods. Safety is also a priority, with regulations and certifications in place to ensure the safety of workers and the environment.

Furthermore, the market is characterized by continuous innovation, with a focus on improving efficiency, reducing waste, and enhancing fiber quality. The use of single roller gins, for instance, has become increasingly popular due to their ability to process cotton more efficiently and with less waste. Cotton fiber recycling is another area of focus, with the potential to reduce the environmental impact of cotton production and processing. Cotton traceability and textile trends are also important considerations, as consumers increasingly demand transparency and sustainability in their textile purchases. Cotton bedding, towels, and other home textiles are significant markets. Cotton tracking technologies are improving the process by reducing cotton ginning dust and enhancing cotton genetics, while cotton fiber analysis helps determine the cotton origin, driving the demand for cotton apparel and cotton clothing in the global market.

|

Market Scope |

|

|

Report Coverage |

Details |

|

Page number |

210 |

|

Base year |

2024 |

|

Historic period |

2019-2023 |

|

Forecast period |

2025-2029 |

|

Growth momentum & CAGR |

Accelerate at a CAGR of 3.3% |

|

Market growth 2025-2029 |

USD 25.6 million |

|

Market structure |

Fragmented |

|

YoY growth 2024-2025(%) |

3.0 |

|

Key countries |

China, US, Japan, India, South Korea, Australia, Canada, UK, Brazil, Germany, |

|

Competitive landscape |

Leading Companies, Market Positioning of Companies, Competitive Strategies, and Industry Risks |

What are the Key Data Covered in this Market Research and Growth Report?

- CAGR of the industry during the forecast period

- Detailed information on factors that will drive the market growth and forecasting between 2025 and 2029

- Precise estimation of the size of the market and its contribution of the industry in focus to the parent market

- Accurate predictions about upcoming growth and trends and changes in consumer behaviour

- Growth of the market across APAC, North America, Europe, South America, Middle East and Africa,

- Thorough analysis of the market's competitive landscape and detailed information about companies

- Comprehensive analysis of factors that will challenge the market growth of industry companies

We can help! Our analysts can customize this market research report to meet your requirements.