Cryogenic Insulation Market Size 2024-2028

The cryogenic insulation market size is forecast to increase by USD 562.8 million, at a CAGR of 5.2% between 2023 and 2028.

- The market is driven by the increasing demand for clean and eco-friendly energy resources. Natural gas vehicle (NGV) infrastructure expansion is a significant trend in this market, as governments worldwide invest in sustainable transportation solutions. However, the market faces challenges, including the cessation of World Bank funding for exploration and production (E and P) activities, which may hinder growth in some regions. Companies in the cryogenic insulation industry must navigate these challenges by exploring alternative funding sources and partnerships to maintain market momentum.

- Additionally, innovation in insulation materials and technologies, such as advanced superconducting materials and nanotechnology, presents opportunities for competitive differentiation and market expansion. Companies seeking to capitalize on these opportunities must stay informed of regulatory developments and consumer preferences, while also addressing the sustainability concerns associated with the production and disposal of cryogenic insulation materials.

What will be the Size of the Cryogenic Insulation Market during the forecast period?

Explore in-depth regional segment analysis with market size data - historical 2018-2022 and forecasts 2024-2028 - in the full report.

Request Free Sample

The market continues to evolve, driven by advancements in high-vacuum technology and scientific research. Liquid nitrogen and other cryogenic fluids play a crucial role in this dynamic industry, as insulation systems employing multi-layer designs and cryogenic sensors ensure optimal insulation resistance and insulation efficiency. Refrigeration technology and cryogenic certification are integral components of this sector, with insulation standards and insulation density being key considerations for manufacturers. Heat transfer and insulation design are essential aspects of cryogenic applications, which span across various industries, including aerospace, industrial processes, and biomedical sectors. Cryogenic manufacturing and the production of cryogenic tanks and cryogenic piping require insulation thickness and durability, while insulation optimization and insulation materials, such as aerogel and powder insulation, are essential for maintaining insulation performance in low-temperature applications.

Cryogenic engineering and cryogenic control systems are essential for managing insulation efficiency and insulation maintenance, as insulation degradation and insulation cost are ongoing concerns. The evolving market landscape also includes the use of cryogenic fluids in energy storage and food preservation, as well as the development of cryogenic pumps and cryogenic valves for efficient handling and transportation of cryogenic materials. The ongoing research and development in this sector continue to unfold, with innovations in insulation materials, insulation applications, and insulation testing driving growth and shaping the future of the market.

How is this Cryogenic Insulation Industry segmented?

The cryogenic insulation industry research report provides comprehensive data (region-wise segment analysis), with forecasts and estimates in "USD million" for the period 2024-2028, as well as historical data from 2018-2022 for the following segments.

- Application

- LPG/LNG transport and storage

- Chemicals

- Energy and power

- Metallurgical

- Others

- Geography

- North America

- US

- Canada

- Europe

- Germany

- APAC

- China

- South America

- Brazil

- Rest of World (ROW)

- North America

.

By Application Insights

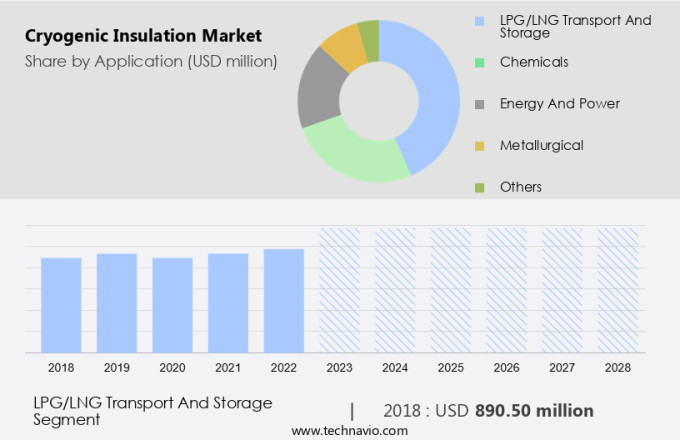

The lpg/lng transport and storage segment is estimated to witness significant growth during the forecast period.

The market encompasses a range of applications and technologies, including insulation systems for cryogenic vessels and dewar flasks, heat transfer and cryogenic control systems, and insulation materials for low-temperature applications. Cryogenic testing is crucial in ensuring the insulation's efficiency and durability, with regulations mandating stringent standards for insulation thickness and performance. Industrial processes such as cryogenic manufacturing and scientific research rely on insulation systems to maintain the required low temperatures. Liquid nitrogen and liquid helium are commonly used cryogenic fluids in various industries, including food preservation, biomedical applications, and space exploration. Cryogenic engineering designs insulation systems for cryogenic piping, tanks, and valves, utilizing materials with high insulation efficiency and low thermal conductivity.

Multi-layer insulation, vacuum insulation panels, and aerogel insulation are popular insulation materials used in cryogenic applications due to their high insulation performance and durability. Cryogenic pumps and high-vacuum technology are essential components in the production and handling of cryogenic fluids. Cryogenic sensors and certification are also crucial in monitoring and ensuring the safety and efficiency of insulation systems. Cryogenic insulation plays a significant role in energy storage and refrigeration technology, with applications in the aerospace industry and space exploration. Cryogenic storage and maintenance are essential for preserving and transporting sensitive materials, such as biological samples and cryogenically frozen food.

Cryogenic actuators are used in various industries, including oil and gas, to control valves and pumps in cryogenic environments. Insulation optimization and insulation design are essential aspects of cryogenic engineering, ensuring the insulation's cost-effectiveness and efficiency. Cryogenic insulation materials must be able to withstand the extreme temperatures and pressures while maintaining their insulation properties. Cryogenic insulation's resistance to insulation degradation and insulation resistance are crucial factors in its long-term performance and reliability.

The LPG/LNG transport and storage segment was valued at USD 890.50 million in 2018 and showed a gradual increase during the forecast period.

Regional Analysis

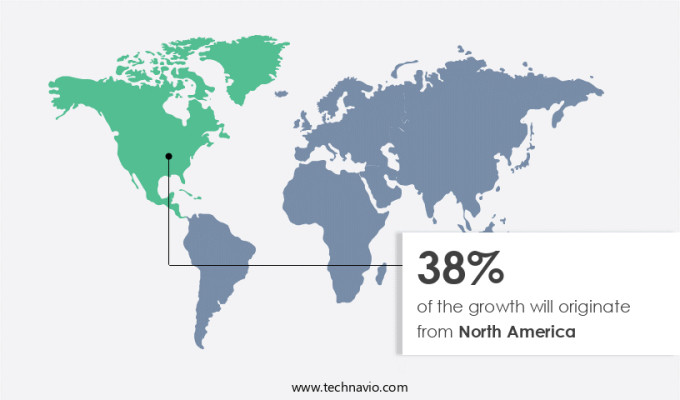

North America is estimated to contribute 38% to the growth of the global market during the forecast period.Technavio's analysts have elaborately explained the regional trends and drivers that shape the market during the forecast period.

The market is witnessing significant growth, with North America leading the charge. This region's dominance is attributed to substantial investments in manufacturing, LNG, healthcare, and aerospace sectors. Advanced technological developments and stringent environmental regulations further bolster the market's growth. The presence of major industry players in North America fosters innovation and supports the development of cryogenic insulation solutions. The increasing demand for LNG is a primary driver for market expansion, with the U.S. Government's plans to expand gas-based power generation capacity further fueling growth. Cryogenic insulation plays a crucial role in maintaining the extreme low temperatures required for LNG storage and transportation.

In the healthcare sector, cryogenic insulation is essential for storing and transporting cryopreserved organs and biological samples. Biomedical applications demand high insulation performance, efficiency, and durability, driving the development of advanced insulation systems. Heat transfer and thermal conductivity are critical factors in the design and application of cryogenic insulation. Multi-layer insulation, vacuum insulation panels, and aerogel insulation are popular choices due to their high insulation efficiency and low thermal conductivity. Cryogenic insulation is also vital in the aerospace industry for space exploration and satellite applications. Cryogenic tanks, cryogenic pumps, and dewar flasks are essential components of spacecraft, requiring high-performance insulation to maintain the extreme temperatures required for space travel.

Cryogenic insulation is also used in industrial processes, energy storage, and food preservation. Insulation optimization, maintenance, and degradation are essential considerations for the long-term performance and cost-effectiveness of cryogenic insulation systems. The market is expected to continue growing due to the increasing demand for LNG, advancements in refrigeration technology, and the expanding applications in various industries. Cryogenic certification, insulation standards, and regulations play a crucial role in ensuring the safety and efficiency of cryogenic insulation systems.

Market Dynamics

Our researchers analyzed the data with 2023 as the base year, along with the key drivers, trends, and challenges. A holistic analysis of drivers will help companies refine their marketing strategies to gain a competitive advantage.

What are the key market drivers leading to the rise in the adoption of Cryogenic Insulation Industry?

- The demand for clean and eco-friendly energy resources serves as the primary market driver, as an increasing number of consumers and businesses prioritize sustainability and seek to reduce their carbon footprint.

- The market is experiencing significant growth due to the increasing demand for insulation optimization in various industries, particularly in the aerospace sector. The use of advanced insulation materials, such as aerogel insulation and vacuum insulation panels, is gaining popularity due to their excellent insulation properties and ability to maintain low temperatures. Insulation maintenance and the prevention of insulation degradation are crucial factors driving market growth. The transportation of cryogenic fluids, such as liquid nitrogen and liquid hydrogen, for energy storage and food preservation applications require effective insulation to maintain the desired temperature and prevent energy loss.

- The cost-effectiveness of insulation materials and regulations governing their use are essential considerations for market participants. The aerospace industry's stringent insulation regulations ensure the safety and reliability of spacecraft and other aircraft that transport cryogenic fluids. In the food preservation industry, the use of cryogenic insulation is essential to maintain the quality and freshness of perishable goods during transportation and storage. The increasing demand for energy storage solutions and the need for efficient insulation systems are expected to further boost market growth. Despite the advantages, the high cost of some insulation materials and the challenges in their production and application may limit market growth to some extent.

- However, ongoing research and development efforts are expected to address these challenges and drive innovation in the market.

What are the market trends shaping the Cryogenic Insulation Industry?

- The emerging market trend involves increased government support for the infrastructure development of Natural Gas Vehicles (NGVs). This significant investment is expected to foster growth in the NGV sector.

- Natural gas is gaining recognition as a viable solution for reducing greenhouse gas emissions. Governments worldwide support the establishment of natural gas refueling stations, offering incentives such as tax rebates and subsidies. In the US, LNG and CNG are considered alternative fuels, with the Oklahoma government providing tax credits for CNG vehicles and their refueling. Iran is a leading country in the use of natural gas vehicles (NGVs) and natural gas refueling stations. The Iranian government encourages private sector involvement in constructing natural gas stations through subsidies for CNG and reducing those for diesel and gasoline. This trend is expected to continue driving the growth of the market, as natural gas infrastructure requires advanced insulation to maintain the extreme low temperatures necessary for transportation and storage.

- Cryogenic insulation plays a crucial role in maintaining the efficiency and safety of natural gas infrastructure, making it a key component in the transition to cleaner energy sources.

What challenges does the Cryogenic Insulation Industry face during its growth?

- The cessation of World Bank funding poses a significant challenge to the growth of the exploration and production (E&P) industry. This financial support is crucial for the expansion and development of E&P projects, and its absence can hinder industry progression.

- The market is witnessing significant growth due to the increasing adoption of high-vacuum technology in scientific research and the expansion of refrigeration technology in various industries. Liquid nitrogen, a commonly used cryogen, is increasingly being utilized in insulation systems for maintaining extremely low temperatures. Cryogenic sensors, which require high insulation resistance, are a crucial component of these systems. The market's growth can also be attributed to the increasing demand for cryogenic certification and adherence to insulation standards. Insulation density, a critical factor in cryogenic insulation, is continually improving due to advancements in technology.

- Cryogenic vessels, essential for storing and transporting cryogens, are also witnessing increased demand, particularly in biomedical applications. The World Bank's decision to fund countries unable to finance E and P activities on their own and promote the adoption of low-carbon clean energy fuels is expected to further boost the market's growth. The announcement of carbon emissions from projects funded by the World Bank will also encourage transparency and accountability in the industry. In conclusion, the market is experiencing robust growth due to technological advancements, increasing demand from various industries, and regulatory initiatives.

Exclusive Customer Landscape

The cryogenic insulation market forecasting report includes the adoption lifecycle of the market, covering from the innovator's stage to the laggard's stage. It focuses on adoption rates in different regions based on penetration. Furthermore, the cryogenic insulation market report also includes key purchase criteria and drivers of price sensitivity to help companies evaluate and develop their market growth analysis strategies.

Customer Landscape

Key Companies & Market Insights

Companies are implementing various strategies, such as strategic alliances, cryogenic insulation market forecast, partnerships, mergers and acquisitions, geographical expansion, and product/service launches, to enhance their presence in the industry.

Altrad Group - As a leading provider in the cryogenic insulation industry, we specialize in implementing advanced insulation solutions during the construction phase of liquefied natural gas (LNG) facilities.

The industry research and growth report includes detailed analyses of the competitive landscape of the market and information about key companies, including:

- Altrad Group

- Amol Minechem Ltd.

- Armacell International SA

- Aspen Aerogels Inc.

- BASF SE

- Cabot Corp.

- Compagnie de Saint-Gobain S.A.

- Dunmore Corp.

- G H ISOLIERUNG GmbH

- Gulf Perlite LLC

- Imerys S.A.

- Industrial Dielectrics Inc.

- Isolatie Combinatie Beverwijk B.V.

- Johns Manville Corp.

- NICHIAS Corp

- Owens Corning

- Rochling SE and Co. KG

- RPM International Inc.

- Unifrax I LLC

- Zhongshan Xinchuang Thermal Insulation Material Co. Ltd.

Qualitative and quantitative analysis of companies has been conducted to help clients understand the wider business environment as well as the strengths and weaknesses of key industry players. Data is qualitatively analyzed to categorize companies as pure play, category-focused, industry-focused, and diversified; it is quantitatively analyzed to categorize companies as dominant, leading, strong, tentative, and weak.

Recent Development and News in Cryogenic Insulation Market

- In February 2023, Thermal Technologies, a leading cryogenic insulation provider, announced the launch of its new product line, CryoShield XT, featuring advanced insulation materials and improved thermal performance (Thermal Technologies Press Release).

- In July 2024, Linde plc and Air Products and Chemicals, Inc. entered into a strategic partnership to collaborate on the development and commercialization of advanced cryogenic insulation solutions, combining their expertise in gases and materials technology (Linde plc Press Release).

- In October 2024, 3M announced a significant investment of USD150 million in its cryogenic insulation manufacturing facility in the United States, expanding its production capacity and enhancing its market presence (3M Press Release).

- In March 2025, the European Union passed new regulations mandating the use of energy-efficient cryogenic insulation in various industries, creating a substantial growth opportunity for market participants (European Commission Press Release).

Research Analyst Overview

- The market encompasses various aspects, including cryogenic pressure, insulation testing procedures, and cryogenic handling. Advanced insulation materials, such as composites and coatings, play a crucial role in optimizing thermal resistance and ensuring cryogenic safety during cryogenic temperature extremes. Cryogenic simulation and data acquisition are essential for cryogenic industry associations to establish certification standards, while insulation innovation continues to drive advancements in insulation assembly methods and cryogenic flow control. Cryogenic leak detection and insulation lifespan are critical concerns for industries dealing with cryogenic transport and storage. Cryogenic research facilities employ cryogenic modeling and level monitoring to enhance understanding of insulation behavior under extreme conditions.

- Cryogenic contamination and insulation recycling are also significant areas of focus to minimize environmental impact and reduce costs. Cryogenic training programs ensure professionals are equipped with the necessary skills to handle insulation effectively and maintain insulation systems' integrity. Heat flux is another essential factor in cryogenic insulation design and performance assessment.

Dive into Technavio's robust research methodology, blending expert interviews, extensive data synthesis, and validated models for unparalleled Cryogenic Insulation Market insights. See full methodology.

|

Market Scope |

|

|

Report Coverage |

Details |

|

Page number |

142 |

|

Base year |

2023 |

|

Historic period |

2018-2022 |

|

Forecast period |

2024-2028 |

|

Growth momentum & CAGR |

Accelerate at a CAGR of 5.2% |

|

Market growth 2024-2028 |

USD 562.8 million |

|

Market structure |

Fragmented |

|

YoY growth 2023-2024(%) |

4.9 |

|

Key countries |

US, China, Germany, Canada, and Brazil |

|

Competitive landscape |

Leading Companies, Market Positioning of Companies, Competitive Strategies, and Industry Risks |

What are the Key Data Covered in this Cryogenic Insulation Market Research and Growth Report?

- CAGR of the Cryogenic Insulation industry during the forecast period

- Detailed information on factors that will drive the growth and forecasting between 2024 and 2028

- Precise estimation of the size of the market and its contribution of the industry in focus to the parent market

- Accurate predictions about upcoming growth and trends and changes in consumer behaviour

- Growth of the market across North America, Europe, APAC, South America, and Middle East and Africa

- Thorough analysis of the market's competitive landscape and detailed information about companies

- Comprehensive analysis of factors that will challenge the cryogenic insulation market growth of industry companies

We can help! Our analysts can customize this cryogenic insulation market research report to meet your requirements.