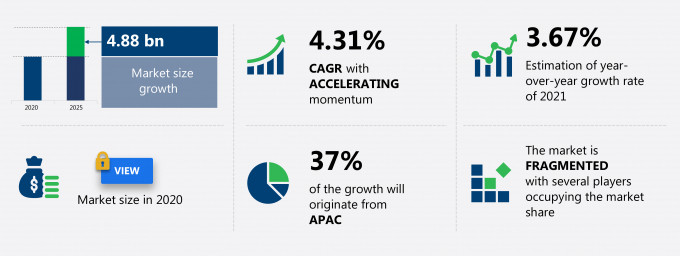

The electric drives market share is expected to increase by USD 4.88 billion from 2020 to 2025, and the market’s growth momentum will accelerate at a CAGR of 4.31%.

This electric drives market research report provides valuable insights on the post COVID-19 impact on the market, which will help companies evaluate their business approaches. Furthermore, this report extensively covers electric drives market segmentation by product (AC drives and DC drives), end-user (process industry and discrete industry), and geography (APAC, Europe, North America, South America, MEA, APAC, Europe, North America, South America, and MEA). The electric drives market report also offers information on several market vendors, including ABB Ltd., Danfoss AS, Mitsubishi Electric Corp., Nidec Corp., Rockwell Automation Inc., Schneider Electric SE, Siemens AG, Toshiba Corp., WEG Equipamentos Eletricos SA, and Yaskawa Electric Corp. among others.

What will the Electric Drives Market Size be During the Forecast Period?

Download the Free Report Sample to Unlock the Electric Drives Market Size for the Forecast Period and Other Important Statistics

Electric Drives Market: Key Drivers, Trends, and Challenges

Based on our research output, there has been a negative impact on the market growth during and post COVID-19 era. The increasing focus on automating manufacturing process es is notably driving the electric drives market growth, although factors such as high cost of installation and maintenance may impede market growth. Our research analysts have studied the historical data and deduced the key market drivers and the COVID-19 pandemic impact on the electric drives industry. The holistic analysis of the drivers will help in deducing end goals and refining marketing strategies to gain a competitive edge.

Key Electric Drives Market Driver

Increasing focus on automating manufacturing processes is the major driver influencing the electric drives market. Automation has become prevalent across process and discrete industries for improved production and efficiency. Various manufacturing processes have been mechanized, and various steps are being undertaken by original equipment manufacturers (OEMs) to produce automated machines. AC drives are among the electric drives that can be connected to multiple motors and pumps, and based on the feedback, they can regulate the motor frequency to achieve the desired speed. This allows effective operational control and lower manual intervention to regulate motor speed. All these factors have rendered electric drives, such as servo drives and AC drives, an effective option for enhancing motor operations in precision applications, such as in conveyors, robotics, and material-handling processes.As most motors used in industrial operations are a critical part of the manufacturing process, any uneven circumstances can affect the operational efficiency and result in high OPEX and lower revenue. Therefore, most industrial operators are switching toward electric drives to automate their motor operating process and increase their operational efficiency.

Key Electric Drives Market Trend

Technological advances in electric drives are the major trend influencing the electric drives market. onventional AC drives use active front-end (AFE) rectifier and multi-purpose transformers to mitigate harmonics. Although this additional equipment helps in mitigating harmonics during operations, it has downsides, such as an increase in wiring requirement, space requirement, and cost. To overcome this challenge, vendors are focusing on matrix design in AC drives. In conventional AC drives, due to the presence of the DC bus, the drive draws non-linear current, which creates harmonics. Whereas in the matrix design, electric drives use nine bi-directional IGBTs, which are arranged in a matrix design to generate AC output from AC input, bypassing any need for DC bus. When a motor is stopped suddenly, the driven load is higher than the driving load; in such cases, the motor acts as a generator, thereby sending voltage back to the drives. As conventional electric drives made use of dynamic braking resistors to divert the regenerated power to protect the DC bus from the over-voltage condition, leading to low optimization of power utilization. The development of matrix bi-directional arrangement helps in directing back to the power source, ensuring optimum utilization of energy during the motor control operation. This arrangement provides protection from non-linear loads and ensures high energy savings through power regeneration. With a growing focus on energy efficiency, the demand for regenerative electric drives is expected to increase during the forecast period.

Key Electric Drives Market Challenge

The high cost of installation and maintenance is a major hindrance to the electric drives market. The major issue for electric drives is operating with inappropriate power supply, such as overvoltage and under-voltage. These drives require a proper power supply to work efficiently, as control panels in electric drives can vary the frequency only when they receive a fixed voltage. To solve this issue, drives are integrated with harmonic mitigation devices. However, such devices increase the size and overall cost of drives. In addition, cooling facilities are required to regulate the heat and improve the performance of drives, leading to higher costs. The other factors that increase the cost of electric drives include customized requirements and raising the horsepower capacity of electric drives. Though electric drives provide better ROI over a long duration, end-users must make significant investments compared to the economical alternatives for motor control methods, such as throttling valves or hydraulic couplers, which are used with pumps to control the speed of pumping operations. The high cost is a major obstacle for end-users of electric drives. SMEs, due to the shortage of capital, resort to economical traditional methods. Although these traditional motor control methods are not energy-efficient, the high overall cost of implementing and maintaining electric drives tends to avert end-users from deploying electric drives.

This electric drives market analysis report also provides detailed information on other upcoming trends and challenges that will have a far-reaching effect on the market growth. The actionable insights on the trends and challenges will help companies evaluate and develop growth strategies for 2021-2025.

Parent Market Analysis

Technavio categorizes the global electric drives market as a part of the global electrical components and equipment market within the global electrical equipment market. Our research report has extensively covered external factors influencing the parent market growth potential in the coming years, which will determine the levels of growth of the electric drives market during the forecast period.

Who are the Major Electric Drives Market Vendors?

The report analyzes the market’s competitive landscape and offers information on several market vendors, including:

- ABB Ltd.

- Danfoss AS

- Mitsubishi Electric Corp.

- Nidec Corp.

- Rockwell Automation Inc.

- Schneider Electric SE

- Siemens AG

- Toshiba Corp.

- WEG Equipamentos Eletricos SA

- Yaskawa Electric Corp.

This statistical study of the electric drives market encompasses successful business strategies deployed by the key vendors. The electric drives market is fragmented and the vendors are deploying growth strategies such as organic and inorganic strategies to compete in the market.

To make the most of the opportunities and recover from post COVID-19 impact, market vendors should focus more on the growth prospects in the fast-growing segments, while maintaining their positions in the slow-growing segments.

The electric drives market forecast report offers in-depth insights into key vendor profiles. The profiles include information on the production, sustainability, and prospects of the leading companies.

Electric Drives Market Value Chain Analysis

Our report provides extensive information on the value chain analysis for the electric drives market, which vendors can leverage to gain a competitive advantage during the forecast period. The end-to-end understanding of the value chain is essential in profit margin optimization and evaluation of business strategies. The data available in our value chain analysis segment can help vendors drive costs and enhance customer services during the forecast period.

The value chain of global electrical components and equipment market includes the following core components:

- Inputs

- Inbound logistics

- Operations

- Outbound logistics

- Marketing and sales

- Service

- Support activities

- Innovation

The report has further elucidated on other innovative approaches being followed by manufacturers to ensure a sustainable market presence.

Which are the Key Regions for Electric Drives Market?

For more insights on the market share of various regions Request for a FREE sample now!

37% of the market’s growth will originate from APAC during the forecast period. China and Japan are the key markets for electric drives in APAC. Market growth in this region will be faster than the growth of the market in other regions.

The growing industrialization is one of the prime factors will facilitate the electric drives market growth in APAC over the forecast period. This market research report entails detailed information on the competitive intelligence, marketing gaps, and regional opportunities in store for vendors, which will assist in creating efficient business plans.

COVID Impact and Recovery Analysis

The market in the region witnessed various challenges due to the COVID-19 pandemic in 2020. India, Pakistan, Bangladesh, and China are some of the countries that have been affected by the pandemic in the region. For instance, according to the European Centre for Disease Prevention and Control, as of January 2021, the total number of COVID-19 cases in India reached 10.9 million. Some of the countries in the region have announced lockdown measurements, including stringent travel restrictions. The CAPEX on manufacturing activities and developments has been reduced as a result of a halt in operations and a reduction in demand. For instance, in February 2021, Auckland, New Zealand, entered a lockdown after the discovery of new cases of COVID-19. Hence, the closure of manufacturing units due to COVID-19 has affected the demand for electric drives in the manufacturing sector, which, in turn, can hinder the growth potential of the market in the region during the forecast period.Vendors are finding it difficult to cope up with high supply-demand fluctuation due to the COVID-19 pandemic. Electrical drive technology is indispensable in industrial production. It plays a key role in machines and plants for production and logistics processes. The use of mobile robots can help e-commerce companies focus on the express delivery of goods and services. Such developments are expected to provide high growth opportunities for vendors that are focused on automation through electric drives during the forecast period.

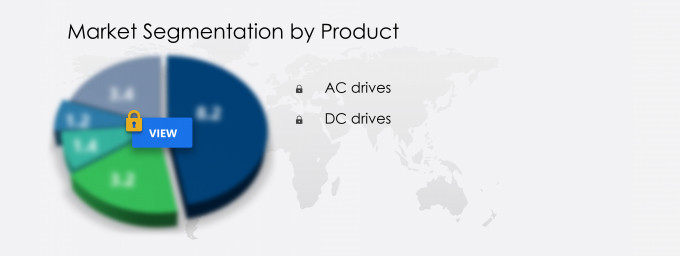

What are the Revenue-generating Product Segments in the Electric Drives Market?

To gain further insights on the market contribution of various segments Request for a FREE sample

AC drives have simplified operations and provide higher efficiency compared with DC drives. Therefore, they are the most suitable devices to control motor movement in industries such as food and beverages, water and wastewater treatment, automotive, oil and gas, and others. Rising investments in these industries will support the growth of the market in this AC drives segment during the forecast period. Hence, the growth of the market segment will exhibit a fast growth rate during the forecast period.

Besides the above-mentioned factors, the post COVID-19 impact has brought forth a slowdown in or fast tracked the demand for the service or product. This report provides an accurate prediction of the contribution of all the segments to the growth of the electric drives market size and actionable market insights on post COVID-19 impact on each segment.

|

Electric Drives Market Scope |

|

|

Report Coverage |

Details |

|

Page number |

120 |

|

Base year |

2020 |

|

Forecast period |

2021-2025 |

|

Growth momentum & CAGR |

Accelerate at a CAGR of 4.31% |

|

Market growth 2021-2025 |

USD 4.88 billion |

|

Market structure |

Fragmented |

|

YoY growth (%) |

3.67 |

|

Regional analysis |

APAC, Europe, North America, South America, MEA, APAC, Europe, North America, South America, and MEA |

|

Performing market contribution |

APAC at 37% |

|

Key consumer countries |

China, US, Germany, Japan, and UK |

|

Competitive landscape |

Leading companies, Competitive strategies, Consumer engagement scope |

|

Key companies profiled |

ABB Ltd., Danfoss AS, Mitsubishi Electric Corp., Nidec Corp., Rockwell Automation Inc., Schneider Electric SE, Siemens AG, Toshiba Corp., WEG Equipamentos Eletricos SA, and Yaskawa Electric Corp. |

|

Market dynamics |

Parent market analysis, Market growth inducers and obstacles, Fast-growing and slow-growing segment analysis, COVID 19 impact and recovery analysis and future consumer dynamics, Market condition analysis for forecast period |

|

Customization purview |

If our report has not included the data that you are looking for, you can reach out to our analysts and get segments customized. |

What are the Key Data Covered in this Electric Drives Market Report?

- CAGR of the market during the forecast period 2021-2025

- Detailed information on factors that will drive electric drives market growth during the next five years

- Precise estimation of the electric drives market size and its contribution to the parent market

- Accurate predictions on upcoming trends and changes in consumer behavior

- The growth of the electric drives industry across APAC, Europe, North America, South America, MEA, APAC, Europe, North America, South America, and MEA

- A thorough analysis of the market’s competitive landscape and detailed information on vendors

- Comprehensive details of factors that will challenge the growth of electric drives market vendors

We can help! Our analysts can customize this report to meet your requirements. Get in touch