Epoxy Primers Market Size 2024-2028

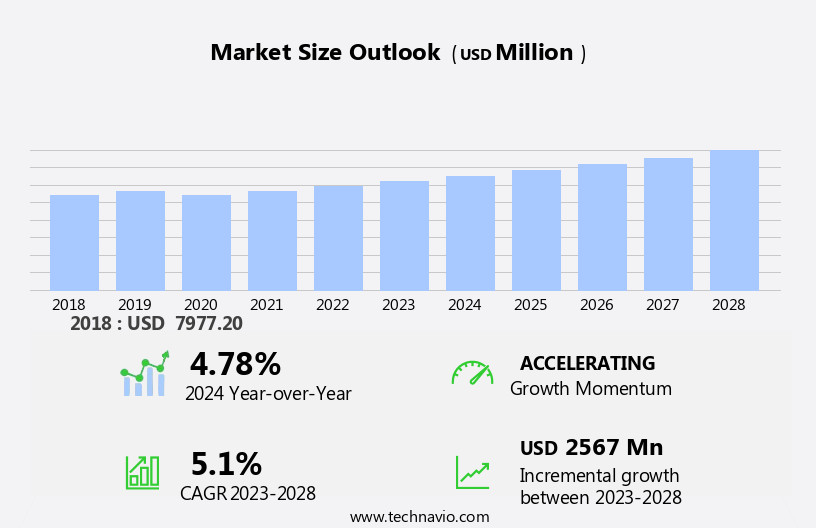

The epoxy primers market size is forecast to increase by USD 2.57 billion at a CAGR of 5.1% between 2023 and 2028.

- Epoxy primers play a crucial role In the protective coatings industry, particularly in applications involving metals such as zinc, galvanized steel, and aluminum. These primers are widely used in various sectors, including construction, aviation, and renewable energy, for priming and coating floors, steel, concrete, and fiberglass. In the US market, they are gaining popularity due to their ability to provide superior corrosion resistance and durability. Key market trends include the increasing implementation of solar reflective epoxy primers, which help reduce energy consumption and improve energy efficiency. Stringent regulations, particularly In the aviation industry, are also driving the demand due to their ability to meet specific performance requirements.

What will be the Size of the Epoxy Primers Market During the Forecast Period?

- The market encompasses a wide range of products used for coating fiberglass, concrete, metal substrates, including stainless steel, galvanized steel, and ferrous metals, in various industries such as building and construction, automotive and transportation, machinery and equipment, and wind energy. Epoxy primers offer superior adhesion and corrosion resistance, making them a preferred choice for priming bare materials. The market is segmented based on technology into solvent-borne and water-borne, with solvent-borne technology dominating due to its superior film formation and durability. However, the increasing environmental regulations are driving the growth of water-borne epoxy primers. The automotive sector, particularly In the production of structural steel primer, is a significant consumer.

- Additionally, the use as an epoxy finish, epoxy sealer, or liquid coating in industries like machinery and equipment, and In the construction of wind plants, is expanding the market's reach. The market is experiencing steady growth due to the increasing demand for high-performance coatings and the need for longer-lasting protective coatings.

- Furthermore, the use in renewable energy applications, such as wind turbines and solar panels, is expected to increase due to their resistance to harsh environmental conditions. However, challenges such as the use of solvents, which contribute to environmental concerns, and the high cost of phosphate-free epoxy primers are limiting the market growth. Nevertheless, the market is expected to grow due to the increasing demand for protective coatings in various industries and the development of new technologies to address the challenges.

How is this Epoxy Primers Industry segmented and which is the largest segment?

The industry research report provides comprehensive data (region-wise segment analysis), with forecasts and estimates in "USD billion" for the period 2024-2028, as well as historical data from 2018-2022 for the following segments.

- Technology

- Solvent-borne

- Waterborne

- Geography

- APAC

- China

- Japan

- Europe

- Germany

- France

- North America

- US

- South America

- Middle East and Africa

- APAC

By Technology Insights

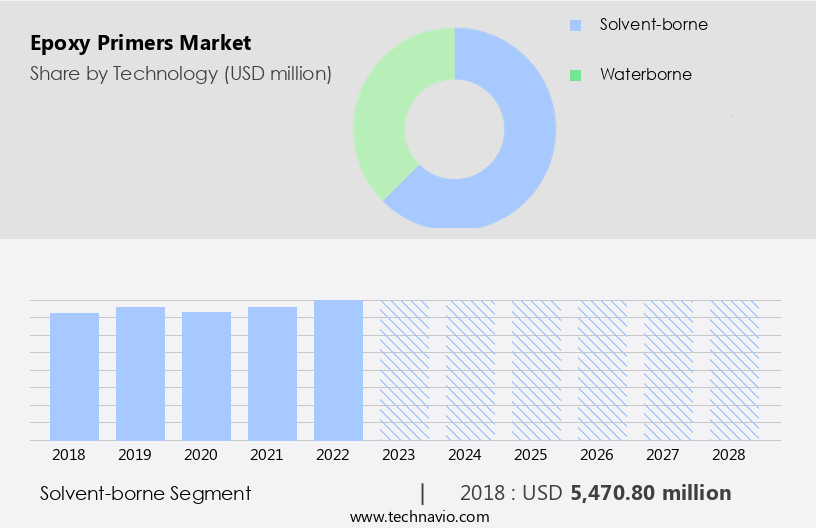

- The solvent-borne segment is estimated to witness significant growth during the forecast period.

Epoxy primers, specifically solvent-borne types, serve as essential protective layers applied to various substrates, including fiberglass, concrete, metal, and wood, to prevent corrosion. Solvent-borne epoxy primers consist of organic compounds and offer greater durability and performance compared to water-borne alternatives during curing. This makes them suitable for applications in humid environments and harsh conditions. Additionally, solvent-borne epoxy primers exhibit high tolerance to petroleum contaminants in concrete surfaces, making them ideal for use in garages and parking structures. The glossier finish of these primers is another advantage, contributing to their popularity. The extensive utilization of solvent-based technology is attributed to its ability to provide robust protection against corrosion.

Epoxy resins, pigments, fillers, additives, and solvents are integral components of these primers. The building and construction sector, automotive and transportation, machinery and equipment, and infrastructure activities are significant end-users of epoxy primers. Environmental regulations and construction activity In the aircraft sector, wind plants, and renewable energy generation are also driving factors for the market growth. Epoxy primers are available in various formats, including liquid coatings, epoxy finishes, and epoxy sealers. Solvent-based techniques are commonly used In the building and construction sector for flooring applications. Epoxy primers are also used as structural steel primers and are available in robocar format. The raw materials used In the production include synthetic resins and various additives.

Get a glance at the market report of share of various segments Request Free Sample

The solvent-borne segment was valued at USD 5.47 billion in 2018 and showed a gradual increase during the forecast period.

Regional Analysis

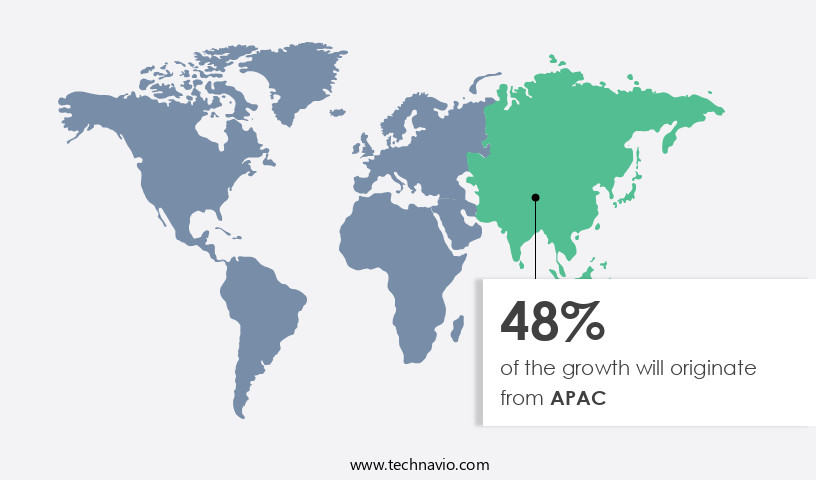

- APAC is estimated to contribute 48% to the growth of the global market during the forecast period.

Technavio's analysts have elaborately explained the regional trends and drivers that shape the market during the forecast period.

For more insights on the market size of various regions, Request Free Sample

The Epoxy Primer market has experienced significant growth due to increasing economic expansion in developing countries, particularly in Asia Pacific (APAC), and the resulting rise in consumer purchasing power. This trend has led to an increase in automotive sales, with many manufacturers relocating production to APAC for cost savings. For instance, BMW announced plans to launch the i4 electric vehicle in Singapore by the end of 2022. Additionally, governments in countries such as Indonesia, Malaysia, and Thailand have offered tax incentives to encourage the production of electric vehicles (EVs). In the building and construction sector, their use is also on the rise due to their superior adhesion properties, particularly for substrates such as concrete, fiberglass, and metal.

Epoxy primers offer protection against corrosion and UV rays, making them ideal for infrastructure projects and wind plants in renewable energy generation. The market is driven by the demand for high-performance coatings in various industries, including automotive, machinery and equipment, and construction. The use of epoxy resins, pigments, fillers, additives, solvents, and other raw materials In the production is expected to continue, with advances in solvent-borne and waterborne technology driving innovation In the market.

Market Dynamics

Our researchers analyzed the data with 2023 as the base year, along with the key drivers, trends, and challenges. A holistic analysis of drivers will help companies refine their marketing strategies to gain a competitive advantage.

What are the key market drivers leading to the rise In the adoption of Epoxy Primers Industry?

Rising number of applications is the key driver of the market.

- Epoxy primers serve as essential protective coatings in various industries, including Building and Construction, Automotive and Transportation, Machinery and Equipment, and Infrastructural Activities. Primarily used for corrosion protection, epoxy primers are applied to steel surfaces, such as structural steel, stainless steel, and ferrous metals, as well as concrete, fiberglass, and wood substrates. These primers offer excellent adhesion to bare materials and provide robust protection against UV rays, moisture, and chemical exposure. In the Building and Construction sector, epoxy primers are used extensively for flooring applications, while In the Automotive sector, they are used as structural steel primers, often replacing zinc phosphate and corrosion inhibiting pigments.

- Epoxy primers are also used In the manufacturing of machinery and equipment, particularly in wind plants and other renewable energy generation facilities, due to their resistance to harsh environments. Solvent-borne and water-borne technologies are commonly used In the production of epoxy primers. Epoxy resins, synthetic resins, pigments, fillers, additives, and solvents are the primary raw materials used In the manufacturing process. They offer fast-drying properties and extended overcoat ability, making them suitable for factory applications. They also provide good abrasion resistance, ensuring resistance to mechanical damage during transportation. Environmental regulations play a significant role In the demand, as they offer low VOC (volatile organic compound) content, making them an eco-friendly alternative to traditional solvent-based techniques.

- In the Automotive sector, the use is driven by the increasing demand for fuel efficiency and lightweight vehicles. Similarly, In the Machinery and Equipment segment, the need for longer-lasting coatings to reduce maintenance costs is driving the demand. Thus, epoxy primers offer excellent protection against corrosion, abrasion, and environmental conditions, making them an essential coating solution for various industries. Their versatility, combined with their fast-drying properties and extended overcoat ability, make them a popular choice for applications In the Building and Construction, Automotive and Transportation, Machinery and Equipment, and Infrastructural Activities sectors.

What are the market trends shaping the Epoxy Primers Industry?

Implementation of solar reflective epoxy primers is the upcoming market trend.

- Epoxy primers play a crucial role in enhancing the durability and protection of various substrates, including fiberglass, concrete, metal, and wood, in industries such as Building and Construction, Automotive and Transportation, Machinery and Equipment, and Infrastructural Activities. The market is driven by several factors. In the Building and Construction sector, the focus on energy efficiency and reducing heat island effects has led to the increasing adoption of solar reflective epoxy primers. These primers, which reflect infrared radiations and absorb visible light, help mitigate the heat island effect and reduce energy consumption for air conditioning. Acrylic epoxy primers, in particular, are gaining popularity due to their high solar reflective properties and long lifespan.

- In the Automotive sector, the demand is driven by their corrosion-resistant properties and ability to provide a smooth finish for automotive paint. The market is also influenced by environmental regulations, which mandate the use of eco-friendly and low-VOC (volatile organic compound) coatings. The Metal segment, which includes stainless steel, galvanized steel, and ferrous metals, is a significant consumer due to their excellent adhesion properties and resistance to UV rays and corrosion. The use in the Machinery and Equipment and Renewable Energy Generation sectors, such as wind plants, is also on the rise due to their ability to provide a robust protective coating for these applications. The market is expected to grow as the demand for durable and protective coatings continues to increase across various industries.

What challenges does the Epoxy Primers Industry face during its growth?

Stringent regulations affecting market growth is a key challenge affecting the industry growth.

- Epoxy primers are essential protective coatings used in various industries, including Building and Construction, Automotive and Transportation, Machinery and Equipment, and Infrastructural Activities. These primers shield substrates from environmental factors, such as UV rays, temperature extremes, and chemicals, preventing corrosion and weathering. They consist of epoxy resins, pigments, fillers, additives, and solvents. In the Building and Construction sector, epoxy primers are used on fiberglass, concrete, and metal surfaces. In the Automotive sector, they serve as structural steel primers and are used In the manufacturing of zinc phosphate primers and corrosion inhibiting pigments. In the Machinery and Equipment segment, they are used to coat wind plants and other machinery components exposed to harsh conditions.

- Environmental regulations have led to the development of water-borne epoxy primers as an alternative to solvent-borne technology. However, solvent-borne epoxy primers, while effective, pose environmental concerns due to their volatile organic compounds. The automotive sector is a significant consumer, with automotive paint and coatings being a major application. Epoxy primers are available in various forms, including Epoxy finish, Epoxy sealer, and liquid coating. They are used on bare materials such as stainless steel, galvanized steel, ferrous metals, and wood. Adhesion to substrates is crucial for the effective performance. The use is not limited to the above-mentioned industries. They are also used In the Robocar format and in raw materials production. The market dynamics are influenced by factors such as oil prices, demand for renewable energy generation, and the availability of synthetic resins.

Exclusive Customer Landscape

The market forecasting report includes the adoption lifecycle of the market, market growth and forecasting, covering from the innovator's stage to the laggard's stage. It focuses on adoption rates in different regions based on penetration. Furthermore, the market report also includes key purchase criteria and drivers of price sensitivity to help companies evaluate and develop their market growth analysis strategies.

Customer Landscape

Key Companies & Market Insights

Companies are implementing various strategies, such as strategic alliances, market forecast, partnerships, mergers and acquisitions, geographical expansion, and product/service launches, to enhance their presence In the industry.

The industry research and growth report includes detailed analyses of the competitive landscape of the market and information about key companies, including:

- 3M Co.

- Akzo Nobel NV

- Asian Paints Ltd.

- Axalta Coating Systems Ltd.

- BASF SE

- Berger Paints India Ltd

- Carpoly Chemical Group Co. Ltd.

- Clever Polymers

- DuluxGroup Ltd.

- Grand Polycoats Co. Pvt. Ltd.

- Jotun AS

- Kansai Paint Co. Ltd.

- Nippon Paint Holdings Co. Ltd.

- PPG Industries Inc.

- RPM International Inc.

- Sika AG

- The Eastwood Co.

- The Sherwin Williams Co.

- Triangle Coatings Inc.

- Tuff Coat Polymers Pvt. Ltd.

Qualitative and quantitative analysis of companies has been conducted to help clients understand the wider business environment as well as the strengths and weaknesses of key industry players. Data is qualitatively analyzed to categorize companies as pure play, category-focused, industry-focused, and diversified; it is quantitatively analyzed to categorize companies as dominant, leading, strong, tentative, and weak.

Research Analyst Overview

Epoxy primers are essential components in various industries, providing excellent adhesion and protection to diverse substrates. These primers have gained significant traction In the coatings and construction sectors due to their superior performance and versatility. Epoxy primers are widely used In the building and construction industry for both new projects and infrastructure maintenance. They offer excellent resistance to water, chemicals, and UV rays, making them ideal for concrete, fiberglass, and metal applications. In the building and construction sector, epoxy primers are often used in robocar format for large-scale projects, ensuring efficient application and long-lasting results. Furthermore, they play a crucial role In the automotive and transportation sector. They serve as structural steel primers, providing corrosion protection to metal components in vehicles and machinery. They are also used In the aircraft industry due to their high resistance to harsh environmental conditions and excellent adhesion properties. In the machinery and equipment segment, they are used to protect metal surfaces from corrosion and wear. They offer superior resistance to chemicals, solvents, and other harsh conditions, making them an ideal choice for industrial applications. Environmental regulations have driven the demand for water-borne epoxy primers, as they offer lower VOC (volatile organic compound) emissions compared to solvent-borne epoxy primers.

This trend is particularly noticeable In the building and construction sector, where environmental concerns are increasingly important. The market is influenced by several factors, including infrastructural activities, construction activity levels, and raw material prices. The increasing demand for renewable energy generation, such as wind plants, has also contributed to the growth of the market. They are formulated using various raw materials, including epoxy resins, acrylics, alkyds, urethanes, pigments, fillers, and additives. The choice of raw materials depends on the specific application requirements, such as adhesion, durability, and resistance to environmental factors. Solvent-borne and waterborne technologies are the two primary methods used In the production. Solvent-borne techniques offer faster drying times and excellent coverage, while waterborne methods offer lower VOC emissions and better environmental compatibility. Thus, they are an essential component in various industries, offering excellent adhesion and protection to diverse substrates. Their versatility and superior performance make them a popular choice in building and construction, automotive and transportation, machinery and equipment, and other industries. The market is influenced by several factors, including environmental regulations, raw material prices, and infrastructural activities. The future of the market looks promising, with continued growth expected due to their unique properties and increasing demand in various industries.

|

Market Scope |

|

|

Report Coverage |

Details |

|

Page number |

144 |

|

Base year |

2023 |

|

Historic period |

2018-2022 |

|

Forecast period |

2024-2028 |

|

Growth momentum & CAGR |

Accelerate at a CAGR of 5.1% |

|

Market growth 2024-2028 |

USD 2.57 billion |

|

Market structure |

Fragmented |

|

YoY growth 2023-2024(%) |

4.78 |

|

Key countries |

US, China, Japan, Germany, and France |

|

Competitive landscape |

Leading Companies, Market Positioning of Companies, Competitive Strategies, and Industry Risks |

What are the Key Data Covered in this Market Research and Growth Report?

- CAGR of the industry during the forecast period

- Detailed information on factors that will drive the growth and forecasting between 2024 and 2028

- Precise estimation of the size of the market and its contribution of the industry in focus to the parent market

- Accurate predictions about upcoming growth and trends and changes in consumer behaviour

- Growth of the market across APAC, Europe, North America, South America, and Middle East and Africa

- Thorough analysis of the market's competitive landscape and detailed information about companies

- Comprehensive analysis of factors that will challenge the market growth of industry companies

We can help! Our analysts can customize this market research report to meet your requirements.