Fiberglass Mold Market Size 2024-2028

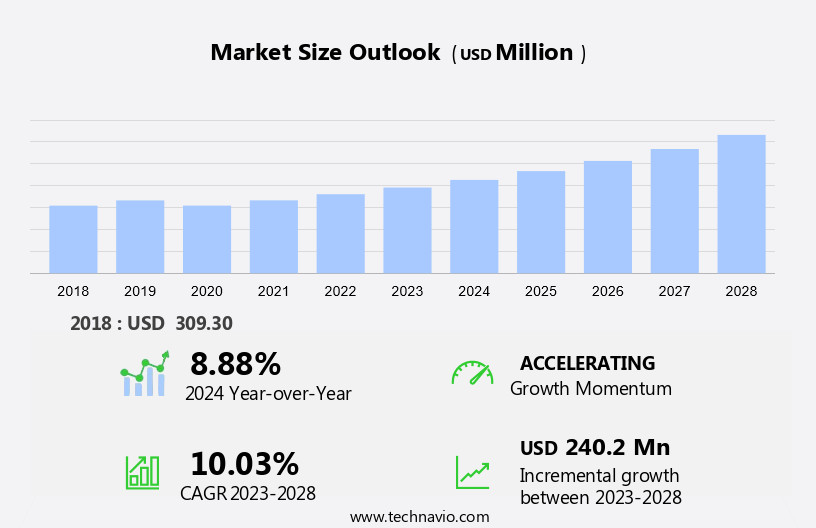

The fiberglass mold market size is forecast to increase by USD 240.2 million at a CAGR of 10.03% between 2023 and 2028.

- The market is experiencing significant growth due to several key trends. One of the primary drivers is the increasing demand for renewable energy, particularly wind energy, which utilizes fiberglass molds extensively In the production of wind turbine blades. Additionally, there is a rising demand for green buildings, leading to an increase In the use of fiberglass molds for insulation and other construction applications. However, the market also faces challenges, including health concerns associated with the production and handling of glass fibers. Producers must ensure strict adherence to safety regulations to mitigate these risks and maintain market growth. Overall, the market is poised for continued expansion, driven by these trends and the growing demand for sustainable energy solutions and eco-friendly construction practices.

What will be the Size of the Fiberglass Mold Market During the Forecast Period?

- The market encompasses the production and sale of fiberglass molds used in various industries for manufacturing fiberglass products. Fiberglass resin, often reinforced with carbon fiber, natural minerals such as silica sand, or advanced materials like s-glass fiberglass, is utilized In the molding process. Polyvinyl alcohol and acetone are commonly used as bonding agents. Key trends In the fiberglass mold industry include the increasing adoption of fiberglass in end-use industries such as wind energy, construction & infrastructure, automotive & transportation, aerospace & defense, marine, storage tanks, boat building, pipes, platforms, grating, doors, sinks, railings, and others. Fiberglass's superior corrosion resistance and lightweight properties make it a popular choice for these applications.

- Moreover, fiberglass molds are also used In the production of composite materials like carbon fiber reinforced polymer (CFRP) and glass fiber reinforced polymer (GFRP). In the aerospace & defense sector, fiberglass molds are used to manufacture complex parts for aircraft and spacecraft. The automotive & transportation industry uses fiberglass molds for producing vehicle components, while the marine industry employs them for boat building. In the construction & infrastructure sector, fiberglass molds are used for manufacturing pipes, tanks, and other structural components. Polyester resin and woven fiberglass cloth are commonly used materials in fiberglass molding. The process involves pouring resin into a mold and allowing it to cure, forming a solid, durable product.

How is this Fiberglass Mold Industry segmented and which is the largest segment?

The fiberglass mold industry research report provides comprehensive data (region-wise segment analysis), with forecasts and estimates in "USD million" for the period 2024-2028, as well as historical data from 2018-2022 for the following segments.

- Resin Type

- Epoxy

- Vinyl Ester

- Polyester

- Others

- End-user

- Wind energy

- Marine

- Aerospace and defense

- Automotive and transportation

- Others

- Geography

- APAC

- China

- India

- Japan

- Europe

- Germany

- North America

- US

- Middle East and Africa

- South America

- APAC

By Resin Type Insights

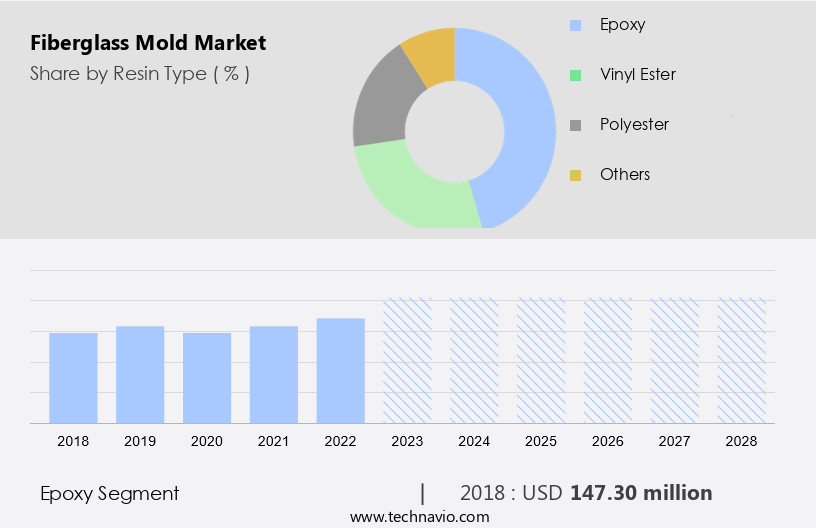

- The epoxy segment is estimated to witness significant growth during the forecast period.

The market is driven by the extensive usage of fiberglass molds in various industries, particularly in wind energy, marine, automotive, and home building materials. Epoxy resin is the leading resin type in this market due to its superior thermal properties, high strength, and durability. Epoxy resin-based molds are widely preferred for their better physical, mechanical, and adhesion properties, which make them suitable for applications in end-use industries. Epoxy resin's low shrinkage and excellent bonding capabilities with fiberglass, wood, and metals make it an ideal choice for boat repair and other applications. Other resins, such as vinyl ester, polyester, phenolic, and polyvinyl alcohol, are also used in fiberglass molding due to their unique properties. Natural minerals like silica sand and carbon fiber are often added to enhance the mold's strength and corrosion resistance. The fiberglass mold industry also incorporates 3D printing technology and cosmetic dyes to cater to diverse market requirements. Fiberglass mold manufacturers offer a range of products, including laminates, gel coats, flanges, and various types of resins.

Get a glance at the Fiberglass Mold Industry report of share of various segments Request Free Sample

The epoxy segment was valued at USD 147.30 million in 2018 and showed a gradual increase during the forecast period.

Regional Analysis

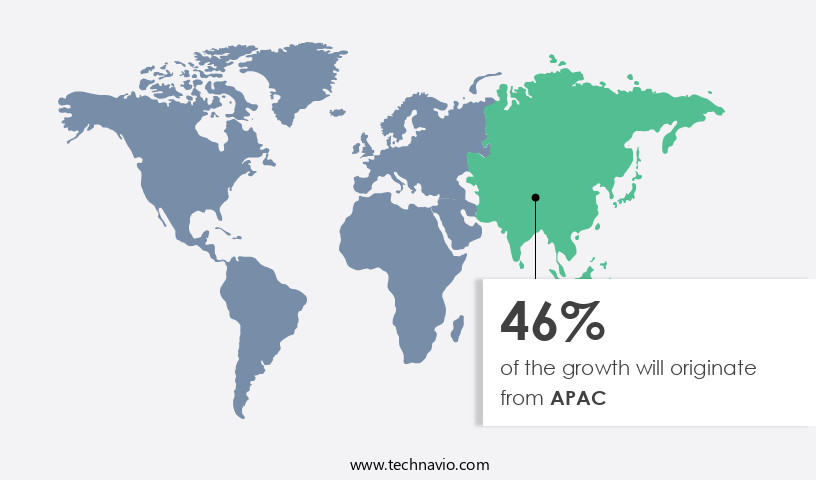

- APAC is estimated to contribute 46% to the growth of the global market during the forecast period.

Technavio's analysts have elaborately explained the regional trends and drivers that shape the market during the forecast period.

For more insights on the market share of various regions, Request Free Sample

The market In the Asia Pacific (APAC) region is experiencing significant growth due to the increasing demand for fiberglass in various industries, including construction, transportation, and electronics and electrical. With countries such as China, Japan, India, South Korea, and Australia being major contributors to the region's economic growth, the demand for fiberglass molds is expected to increase. The wind energy sector, which is a significant end-use industry for fiberglass molds, is experiencing a boom in APAC, with the region accounting for the largest number of installations globally. Additionally, the rise in construction activities driven by increasing per capita income has fueled the demand for fiberglass In the region.

Market Dynamics

Our researchers analyzed the data with 2023 as the base year, along with the key drivers, trends, and challenges. A holistic analysis of drivers will help companies refine their marketing strategies to gain a competitive advantage.

What are the key market drivers leading to the rise In the adoption of Fiberglass Mold Industry?

Increasing demand for wind energy is the key driver of the market.

- The Fiberglass mold industry has witnessed significant growth due to the increasing demand for fiberglass molding in various end-use industries. Fiberglass resin, a key component in this process, is utilized extensively in manufacturing products such as wind energy components, marine applications, automotive sectors, and home building materials, among others. The molding process involves the use of materials like carbon fiber, polyvinyl alcohol, natural minerals, and silica sand, among others, to create molds for various products. Fiberglass's corrosion resistance and lightweight properties make it an ideal choice for industries requiring high durability and strength. For instance, the wind energy sector relies heavily on fiberglass for manufacturing wind turbine blades due to their high energy output and low weight.

- Similarly, the marine industry uses fiberglass for boat building and other applications due to its resistance to water and chemicals. Moreover, advancements in technology have led to the adoption of 3D printing in fiberglass molding, allowing for more intricate designs and customization. Cosmetic dyes and pigments are added to the fiberglass resin to enhance the appearance of the final product. Fiberglass mold manufacturers use various resins like epoxy, vinyl ester, polyester, phenolic, and others, depending on the specific application. Fiberglass molds are used to create various products, including pipes, platforms, grating, doors, sinks, railings, and more. The aerospace and defense industry also uses fiberglass, specifically S-glass fiberglass and polyester resin, for manufacturing components due to their high strength and lightweight properties.

What are the market trends shaping the Fiberglass Mold Industry?

Rise in demand for green building is the upcoming market trend.

- Fiberglass molds play a crucial role In the production of various industries' products, utilizing fiberglass resin In the molding process. The fiberglass mold industry encompasses the creation of molds using materials like carbon fiber, natural minerals such as silica sand, and polymers like polyvinyl alcohol. These molds are essential for manufacturing items with complex shapes and structures, including wind energy components, marine parts, and automotive sectors' components. The fiberglass molding process involves the application of fiberglass reinforcement materials, such as woven fiberglass cloth, chopped strand mat, and S-glass fiberglass, onto a mold using resins like polyester, vinyl ester, epoxy, or phenolic.

- Furthermore, the laminate is then cured with a gel coat, which provides a smooth surface for the final product. Fiberglass molds offer several advantages, including corrosion resistance, lightweight properties, and the ability to create intricate designs. End-use industries, such as wind energy, marine, automotive, and home building materials, rely on fiberglass molds for their durability and versatility. In the wind energy sector, fiberglass molds are used to create wind turbine blades, while In the marine industry, they are used for boat building and the production of pipes, platforms, grating, doors, sinks, railings, and storage tanks. In the automotive sector, fiberglass molds are used for producing body panels, and In the home building materials sector, they are used for producing insulation, roofing, and siding.

What challenges does the Fiberglass Mold Industry face during its growth?

Health hazards associated with glass fibers is a key challenge affecting the industry growth.

- Fiberglass molding is a process used to create molds for various industries using fiberglass resin and reinforcing materials like carbon fiber, natural minerals, and silica sand. The fiberglass mold industry employs different molding processes, including 3D printing, to manufacture molds for end-use industries such as wind energy, marine, automotive sector, home building materials, electronic components, storage tanks, boat building, pipes, platforms, grating, doors, sinks, railings, and aerospace & defence. Fiberglass resins, including polyester, vinyl ester, epoxy, phenolic, and S-glass fiberglass, are used In the molding process. Workers handling fiberglass molds and resins may face health risks due to exposure to fiberglass particles and resins.

- In addition, short-term exposure can cause skin and respiratory irritation, while long-term exposure may lead to more severe health issues like asthma, bronchitis, lung infection, and lung cancer. To minimize health risks, workers should use protective equipment like rubber gloves, filtering masks, and safety goggles. The molding process also involves the use of materials like acetone, paint brushes, woven fiberglass cloth, chopped strand mat, styrene wax, epoxy resins, clear packing tape, wood molding, scissors, and foam. Fibre Glast Developments and other fiberglass mold manufacturers provide solutions to ensure worker safety and produce high-quality fiberglass molds. Understanding the terminology related to fiberglass molding, such as piece, plug, mold, laminate, gel coat, flange, and resins, is essential for professionals In the industry.

Exclusive Customer Landscape

The fiberglass mold market forecasting report includes the adoption lifecycle of the market, covering from the innovator's stage to the laggard's stage. It focuses on adoption rates in different regions based on penetration. Furthermore, the fiberglass mold market report also includes key purchase criteria and drivers of price sensitivity to help companies evaluate and develop their market growth analysis strategies.

Customer Landscape

Key Companies & Market Insights

Companies are implementing various strategies, such as strategic alliances, fiberglass mold market forecast, partnerships, mergers and acquisitions, geographical expansion, and product/service launches, to enhance their presence in the industry.

The industry research and growth report includes detailed analyses of the competitive landscape of the market and information about key companies, including:

- All Plastics And Fiberglass Inc.

- China Jushi Co. Ltd.

- CMDT Manufacturing

- Compagnie de Saint Gobain

- Custom Fibreglassing

- Dencam Composite

- Gurit Holding AG

- Holland Fiberglass and Restoration LLC

- Indutch Composites Technology Pvt. Ltd.

- Janicki Industries Inc.

- Johns Manville

- Molded Fiber Glass Co.

- Nippon Electric Glass Co. Ltd.

- Norco Composites and GRP

- Owens Corning

- PFG FIBER GLASS CORP.

- REV Group Inc.

- Schutz GmbH and Co. KGaA

- Taishan Fiberglass Inc.

- TPI Composites Inc.

Qualitative and quantitative analysis of companies has been conducted to help clients understand the wider business environment as well as the strengths and weaknesses of key industry players. Data is qualitatively analyzed to categorize companies as pure play, category-focused, industry-focused, and diversified; it is quantitatively analyzed to categorize companies as dominant, leading, strong, tentative, and weak.

Research Analyst Overview

The fiberglass molding industry encompasses the production of fiberglass molds, which are utilized in various industries for manufacturing components and products. Fiberglass molds are created using fiberglass resin, a composite material made from natural minerals and synthetic polymers. The molding process involves the application of this resin to a core material, such as balsa wood or foam, and the subsequent layering of fiberglass mats or woven cloth. The fiberglass mold industry caters to diverse end-use sectors, including wind energy, marine, automotive, aerospace & defense, home building materials, and electronic components, among others. The industry's growth is driven by the unique properties of fiberglass molds, such as their corrosion resistance, lightweight nature, and durability.

In addition, carbon fiber and other advanced materials, such as polyvinyl alcohol and phenolic resins, are increasingly being used in fiberglass molding to enhance the performance and functionality of the final products. Technological advancements, including 3D printing and fiberglass mold manufacturers' continuous innovation, are also contributing to the industry's expansion. Fiberglass molds are used extensively In the wind energy sector for manufacturing wind turbine blades and other components due to their lightweight and high-strength properties. In the marine industry, fiberglass molds are employed for boat building and repair, as they offer excellent resistance to water and chemicals. In the automotive sector, fiberglass molds are used for manufacturing vehicle parts, such as body panels and interior components, due to their ability to produce complex shapes and designs.

Furthermore, the aerospace & defense industry relies on fiberglass molds for manufacturing components with high strength-to-weight ratios and excellent resistance to extreme temperatures and environmental conditions. In the home building materials sector, fiberglass molds are used for manufacturing insulation, roofing, and other construction materials. In the electronic components industry, fiberglass molds are used for producing complex and intricate components for various applications. Fiberglass molds are also used In the production of storage tanks, pipes, platforms, grating, doors, sinks, railings, and various other industrial and commercial applications. The industry's future looks promising, with ongoing research and development efforts aimed at improving the performance and sustainability of fiberglass molds.

In addition, in the fiberglass molding process, various resins, such as epoxy, vinyl ester, polyester, and phenolic, are used depending on the specific application requirements. These resins offer different properties, such as high strength, chemical resistance, and thermal stability. The use of gel coat and flange In the molding process further enhances the final product's appearance and functionality. Fiberglass molds are essential in various industries, and their demand is expected to continue growing due to their versatility and unique properties. The industry's future looks promising, with ongoing advancements in materials, manufacturing processes, and applications.

|

Market Scope |

|

|

Report Coverage |

Details |

|

Page number |

154 |

|

Base year |

2023 |

|

Historic period |

2018-2022 |

|

Forecast period |

2024-2028 |

|

Growth momentum & CAGR |

Accelerate at a CAGR of 10.03% |

|

Market growth 2024-2028 |

USD 240.2 million |

|

Market structure |

Fragmented |

|

YoY growth 2023-2024(%) |

8.88 |

|

Key countries |

China, US, Germany, India, and Japan |

|

Competitive landscape |

Leading Companies, market growth and forecasting, Market Positioning of Companies, Competitive Strategies, and Industry Risks |

What are the Key Data Covered in this Fiberglass Mold Market Research and Growth Report?

- CAGR of the Fiberglass Mold industry during the forecast period

- Detailed information on factors that will drive the growth and forecasting between 2024 and 2028

- Precise estimation of the size of the market and its contribution of the industry in focus to the parent market

- Accurate predictions about upcoming growth and trends and changes in consumer behaviour

- Growth of the market across APAC, Europe, North America, Middle East and Africa, and South America

- Thorough analysis of the market's competitive landscape and detailed information about companies

- Comprehensive analysis of factors that will challenge the fiberglass mold market growth of industry companies

We can help! Our analysts can customize this fiberglass mold market research report to meet your requirements.