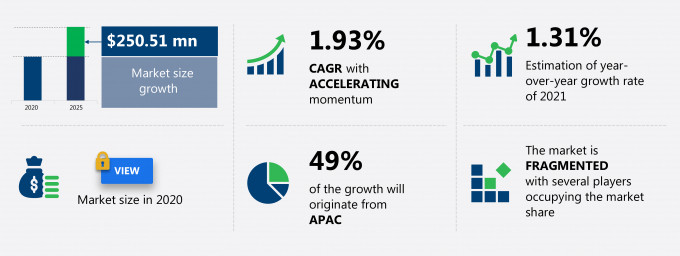

The friction welding machine market share is expected to increase by USD 250.51 million from 2020 to 2025, and the market’s growth momentum will accelerate at a CAGR of 1.93%.

This friction welding machine market research report provides valuable insights on the post COVID-19 impact on the market, which will help companies evaluate their business approaches. Furthermore, this report extensively covers friction welding machine market segmentation by end-user (automotive, aerospace and defense, construction, marine, and others) and geography (APAC, North America, Europe, South America, and MEA). The friction welding machine market report also offers information on several market vendors, including Colfax Corp., ETA Technology Pvt. Ltd., FOOKE Gmbh, Gatwick Technologies Ltd., General Tool Co., Manufacturing Technology Inc., MIDEA GROUP, Norsk Hydro ASA, RV Machine Tools, and Sakae Industries Co. Ltd. among others.

What will the Friction Welding Machine Market Size be During the Forecast Period?

Download the Free Report Sample to Unlock the Friction Welding Machine Market Size for the Forecast Period and Other Important Statistics

Friction Welding Machine Market: Key Drivers, Trends, and Challenges

The high quality welding of dissimilar metals made possible is notably driving the friction welding machine market growth, although factors such as the growing popularity of laser welding technology may impede the market growth. Our research analysts have studied the historical data and deduced the key market drivers and the COVID-19 pandemic impact on the friction welding machine industry. The holistic analysis of the drivers will help in deducing end goals and refining marketing strategies to gain a competitive edge.

Key Friction Welding Machine Market Driver

High-quality welding of dissimilar metals made possible is a major driver fueling the friction welding machine market growth. Friction stir welding is a type of solid-state process that helps in the high-quality welding of materials like aluminum, which are deemed as metal but are difficult to weld. This process is, thus, fast gaining popularity in the transportation sector for manufacturing lightweight vehicles, aircraft, trains, and boats. Fabricators currently face stiff competition in the manufacture of strong yet lightweight products using minimum energy and environment-friendly materials. The entire operation needs to be fast and must involve a minimal operational cost. Thus, the emergence of friction stir welding technology addresses such issues faced by fabricators and serves the purpose of producing high-strength welded joints while simultaneously consuming low energy. The process can be mechanically repeated numerous times with efficient output every time and can be applied over a wide range of materials. The process efficiently fabricates butt and lap joints on a wide variety of material dimensions. The process involves the thrusting of a rotating friction stir welding tool between two clamped plates. The frictional heat causes a plasticized zone to form around the tool. The rotating tool moves along the joint line, thus forming a consolidated solid-phase joint in its wake. As friction stir welding is a solid-state process, it eliminates many of the defects associated with fusion welding techniques, such as shrinkage, solidification cracking, and porosity.

Key Friction Welding Machine Market Trend

The emergence of new materials is a major trend influencing the friction welding machine market growth. There is a significant demand for new technologies driven by the introduction and adoption of new materials that use welding. These new materials help in reducing the weight of the overall finished products as well as lead to lower product and production costs. New materials that use welding in various sectors are listed below. General fabricators are opting for more aluminum, stainless steel, non-ferrous metals, and other exotic materials for designing their products. The introduction of these new materials has enhanced the overall quality of the final product; however, in the process, these materials pose several challenges for the welding process. High-strength steels are prominently used in thinner sections during a welding operation and hence, are more prone to cracks than mild steel. Therefore, preheating the metal or incorporating new welding methodologies has become essential. In addition, during the welding process, aluminum is prone to heat cracking and stress, coupled with oxide layer formation, the prevention of which poses a considerable challenge. A majority of welding equipment manufacturers face such challenges and focus on the development of specific equipment and advanced processes for certain materials.

Key Friction Welding Machine Market Challenge

The growing popularity of laser welding technology is a major hindrance to the friction welding machine market growth. Innovations and advances in technology in the field of lasers have driven their growing popularity and adoption across industries worldwide. One of the most notable applications of lasers, which is gaining momentum, is laser welding technology. This technology is used for welding a wide range of materials having high melting points and heat conduction properties. Laser welding is used for components that need to be manufactured using welding but with minimal thermal distortion and at a faster rate. Laser welding equipment offers higher flexibility, precision, and productivity, thereby enabling mass production. The major target areas for laser welding equipment manufacturers are wind turbine towers and substructures. Sectors like construction, automotive, and aerospace are also creating a huge demand for laser welding equipment. Conversely, Technavio anticipates that market growth might be negatively affected by factors like the dearth of skilled welders and the high initial cost of ownership, as well as the high labor costs.

This friction welding machine market analysis report also provides detailed information on other upcoming trends and challenges that will have a far-reaching effect on the market growth. The actionable insights on the trends and challenges will help companies evaluate and develop growth strategies for 2021-2025.

Parent Market Analysis

Technavio categorizes the friction welding machine market as a part of the global industrial machinery market. Our research report has extensively covered external factors influencing the parent market growth potential in the coming years, which will determine the levels of growth of the friction welding machine market during the forecast period.

Who are the Major Friction Welding Machine Market Vendors?

The report analyzes the market’s competitive landscape and offers information on several market vendors, including:

- Colfax Corp.

- ETA Technology Pvt. Ltd.

- FOOKE Gmbh

- Gatwick Technologies Ltd.

- General Tool Co.

- Manufacturing Technology Inc.

- MIDEA GROUP

- Norsk Hydro ASA

- RV Machine Tools

- Sakae Industries Co. Ltd.

This statistical study of the friction welding machine market encompasses successful business strategies deployed by the key vendors. The friction welding machine market is fragmented and the vendors are deploying organic and inorganic strategies to compete in the market.

To make the most of the opportunities and recover from post COVID-19 impact, market vendors should focus more on the growth prospects in the fast-growing segments, while maintaining their positions in the slow-growing segments.

The friction welding machine market forecast report offers in-depth insights into key vendor profiles. The profiles include information on the production, sustainability, and prospects of the leading companies.

Friction Welding Machine Market Value Chain Analysis

Our report provides extensive information on the value chain analysis for the friction welding machine market, which vendors can leverage to gain a competitive advantage during the forecast period. The end-to-end understanding of the value chain is essential in profit margin optimization and evaluation of business strategies. The data available in our value chain analysis segment can help vendors drive costs and enhance customer services during the forecast period.

The value chain of industrial machinery includes the following core components:

- Inputs

- Inbound logistics

- Operations

- Outbound logistics

- Marketing and sales

- Service

- Support activities

- Innovation

The report has further elucidated other innovative approaches being followed by manufacturers to ensure a sustainable market presence.

Which are the Key Regions for Friction Welding Machine Market?

For more insights on the market share of various regions Request for a FREE sample now!

49% of the market’s growth will originate from APAC during the forecast period. China, Japan, and India are the key markets for friction welding machines market in the region Market growth in this region will be faster than the growth of the market in regions.

Huge investment in the marine industry and the availability of cheap labor will facilitate the friction welding machine market growth in APAC over the forecast period. This market research report entails detailed information on the competitive intelligence, marketing gaps, and regional opportunities in store for vendors, which will assist in creating efficient business plans.

COVID Impact and Recovery Analysis

The friction welding machine market in the region is witnessing various challenges due to COVID-19. COVID-19 has negatively impacted operations in various sectors, such as construction and automotive. For example, in India, the COVID-19 pandemic led to a reduction in the available workforce in the construction sector. The second wave of COVID-19 affected major countries in the region in Q1 2021. This led to temporary factory closures and layoffs, as lockdown restrictions disrupted the supply chain. Moreover, recovery momentum in APAC suffered a significant setback in Q2 2021, as new COVID-19 cases reported due to the highly transmissible Delta variant prompted many countries in the region to reimpose lockdowns. Hence, this is likely to decrease the demand for friction welding machines during the forecast period.

What are the Revenue-generating End User Segments in the Friction Welding Machine Market?

To gain further insights on the market contribution of various segments Request for a FREE sample

The friction welding machine market share growth in the automotive segment will be significant during the forecast period. Owing to the new EU-Ukraine free trade agreement, which came into effect in January 2016, automotive sales in Ukraine recorded a marginal increase. APAC recorded significant growth in automotive sales. Sales of light vehicles in Australia and South Korea witnessed single-digit growth. The South Korean market saw a massive growth rate owing to the 15% reduction in the sales tax. The scenario in Japan remained negative owing to earthquakes, plant accidents, and fuel economy scandals. China and India witnessed identical high growth in sales, with the markets in Vietnam and the Philippines exhibiting robust growth rates as well.The two-wheeler market will continue to be dominated by APAC, which accounts for six of the largest two-wheeler markets, with China as the leader.

This report provides an accurate prediction of the contribution of all the segments to the growth of the friction welding machine market size and actionable market insights on post COVID-19 impact on each segment.

|

Friction Welding Machine Market Scope |

|

|

Report Coverage |

Details |

|

Page number |

120 |

|

Base year |

2020 |

|

Forecast period |

2021-2025 |

|

Growth momentum & CAGR |

Accelerate at a CAGR of 1.93% |

|

Market growth 2021-2025 |

$ 250.51 million |

|

Market structure |

Fragmented |

|

YoY growth (%) |

1.31 |

|

Regional analysis |

APAC, North America, Europe, South America, and MEA |

|

Performing market contribution |

APAC at 49% |

|

Key consumer countries |

China, US, Germany, Japan, and India |

|

Competitive landscape |

Leading companies, Competitive strategies, Consumer engagement scope |

|

Key companies profiled |

Colfax Corp., ETA Technology Pvt. Ltd., FOOKE Gmbh, Gatwick Technologies Ltd., General Tool Co., Manufacturing Technology Inc., MIDEA GROUP, Norsk Hydro ASA, RV Machine Tools, and Sakae Industries Co. Ltd. |

|

Market dynamics |

Parent market analysis, Market growth inducers and obstacles, Fast-growing and slow-growing segment analysis, COVID 19 impact and recovery analysis and future consumer dynamics, Market condition analysis for forecast period |

|

Customization purview |

If our report has not included the data that you are looking for, you can reach out to our analysts and get segments customized. |

What are the Key Data Covered in this Friction Welding Machine Market Report?

- CAGR of the market during the forecast period 2021-2025

- Detailed information on factors that will drive friction welding machine market growth during the next five years

- Precise estimation of the friction welding machine market size and its contribution to the parent market

- Accurate predictions on upcoming trends and changes in consumer behavior

- The growth of the friction welding machine industry across APAC, North America, Europe, South America, and MEA

- A thorough analysis of the market’s competitive landscape and detailed information on vendors

- Comprehensive details of factors that will challenge the growth of friction welding machine market vendors

We can help! Our analysts can customize this report to meet your requirements. Get in touch