Hydraulic Elevators Market Size 2024-2028

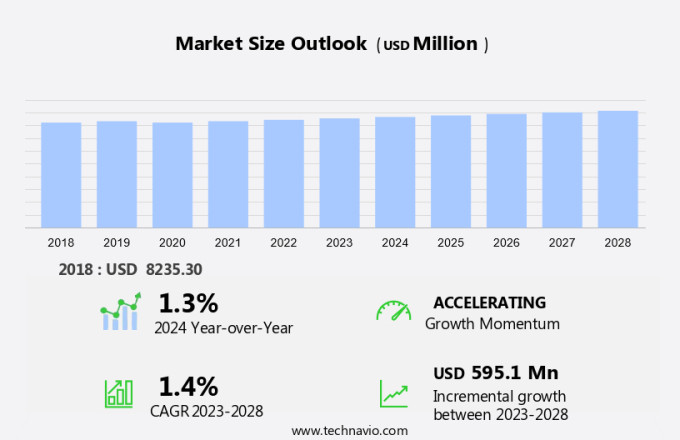

The hydraulic elevators market size is forecast to increase by USD 595.1 million at a CAGR of 1.4% between 2023 and 2028.

- The market is experiencing significant growth due to several key factors. One of the primary drivers is the lesser installation cost of hydraulic elevators compared to traction elevators. Another trend influencing the market is the development of hydraulic infinite linear actuator (HILA) systems, which offer smooth and efficient elevator operation. The use of hydraulic compressors In these elevators ensures efficient and safe operation, making them a preferred choice for businesses seeking to optimize their logistical processes. The use of advanced technologies, such as electronic pumps and cylinders, has improved efficiency and performance, making them a viable option for building owners looking for cost-effective vertical transportation solutions. However, the increasing preference for substitute products, such as pneumatic and MRL elevators, poses a challenge to the market. Despite this, the market is expected to continue growing due to the advantages of hydraulic elevators, including their simplicity, reliability, and flexibility in design and installation. Overall, the market is poised for steady growth In the coming years.

What will be the Size of the Hydraulic Elevators Market During the Forecast Period?

- The market continues to experience steady growth, driven by the demand for vertical transportation solutions in both residential and commercial buildings. Hydraulic elevators offer several advantages, including energy efficiency through the use of hydraulic fluid, durability with components such as cylinders, pistons, and jack modules, and safety features compliant with elevator safety codes. Two common types of hydraulic elevator systems include in-ground jacks and above-ground jacks. In-ground jacks are space-saving designs suitable for low-rise applications, while above-ground jacks are ideal for taller buildings. Elevator cabs, equipped with electronic pumps and jack modules, ensure smooth and reliable vertical transportation.

- Building owners value the quality and reliability of hydraulic elevators for transporting goods and people, as well as their ability to adapt to various building heights and floor heights. As environmental concerns become increasingly important, hydraulic elevators' energy efficiency and minimal machine room requirements make them an attractive choice. In summary, the market In the US is characterized by its focus on durability, energy efficiency, and safety, making it a preferred choice for building owners in various industries.

How is this Hydraulic Elevators Industry segmented and which is the largest segment?

The hydraulic elevators industry research report provides comprehensive data (region-wise segment analysis), with forecasts and estimates in "USD million" for the period 2024-2028, as well as historical data from 2018-2022 for the following segments.

- Type

- Hole-less hydraulic elevators

- Holed hydraulic elevators

- Roped hydraulic elevators

- Geography

- APAC

- China

- India

- Europe

- Germany

- UK

- North America

- US

- Middle East and Africa

- South America

- APAC

By Type Insights

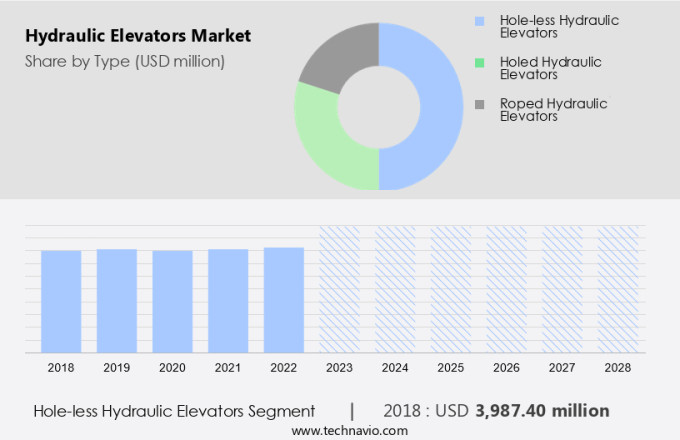

- The hole-less hydraulic elevators segment is estimated to witness significant growth during the forecast period.

Hole-less hydraulic elevators are a type of hydraulic elevator system where pistons and cylinders are mounted above the ground, eliminating the need to drill a hole for cylinders. These systems are ideal for low-rise applications due to their shorter traveling distance. The telescopic cylinders are mounted on a concrete floor, reducing the risk of oil contamination since all hydraulic elements remain above ground. Hole-less hydraulic elevator systems are less rigid than traditional hydraulic elevators due to their above-ground installation. In-ground jacks, jack modules, pistons, and elevator cabs are essential components of these systems. Hole-less hydraulic elevator installations include above-ground jack systems and twinpost jacks. These systems adhere to elevator safety codes and are suitable for various applications.

Get a glance at the Hydraulic Elevators Industry report of share of various segments Request Free Sample

The hole-less hydraulic elevators segment was valued at USD 3.99 billion in 2018 and showed a gradual increase during the forecast period.

Regional Analysis

- APAC is estimated to contribute 45% to the growth of the global market during the forecast period.

Technavio's analysts have elaborately explained the regional trends and drivers that shape the market during the forecast period.

For more insights on the market share of various regions, Request Free Sample

The Asia-Pacific region, specifically China and India, presents substantial growth opportunities for the hydraulic elevator market due to the expanding manufacturing and construction industries. Favorable government policies and increasing FDI inflows In these sectors are driving the demand for hydraulic elevators In the construction of hospitals, hotels, educational institutions, residential buildings, malls, and transportation infrastructure. With an urban population of approximately 63% in 2023, according to The World Bank Group, the need for reliable and convenient lifting solutions for transporting heavy loads is increasingly important. Hydraulic elevators, with their standard lift design and safe lifting capabilities, are a reliable choice for these applications.

Market Dynamics

Our hydraulic elevators market researchers analyzed the data with 2023 as the base year, along with the key drivers, trends, and challenges. A holistic analysis of drivers will help companies refine their marketing strategies to gain a competitive advantage.

What are the key market drivers leading to the rise In the adoption of Hydraulic Elevators Industry?

The lower installation cost of hydraulic elevators compared to traction elevators is the key driver of the market.

- Hydraulic elevators are a cost-effective solution for vertical transportation in regions where budget constraints are a significant factor in building owners' and developers' decision-making processes. In contrast to traction elevators, hydraulic elevators do not necessitate a machine room for installation, resulting in lower on-site costs. The hydraulic elevator system's components, including the cylinder, piston, and hydraulic fluid, are installed at the bottom of the elevator shaft. Energy efficiency and durability are essential considerations for vertical transportation systems. Hydraulic elevators offer energy savings due to their ability to generate heat as a byproduct, which can be used for water heating or space heating.

- Additionally, the use of electronic pumps and hydraulic compressors in modern hydraulic elevator designs enhances energy efficiency. In low-rise applications, hydraulic elevators' space-saving designs make them an attractive option. These elevators are suitable for residential and commercial buildings with floor heights below 15 meters. Furthermore, machine room-less applications and jack modules, such as in-ground jacks and twinpost jacks, offer above-ground installation options, increasing flexibility for building designs. Hydraulic elevators provide reliable and safe vertical movement for transporting goods and heavy loads. They adhere to elevator safety codes and offer features like jack modules and cylinder safety valves to ensure safe lifting.

- However, hydraulic elevators cater to various industries, including construction, manufacturing, and logistics, by providing mobile hydraulic lifts for positioning work materials, trucks, and vehicle lifts for safe working conditions. Maintaining hydraulic elevators requires regular checks and servicing to ensure safe and efficient operation. Proper maintenance practices help reduce the risk of serious injuries, such as extreme pressure injuries from puncturing skin and ensure the longevity of the system.

What are the market trends shaping the Hydraulic Elevators Industry?

The development of a hydraulic infinite linear actuator (HILA) system is the upcoming market trend.

- The market is witnessing significant growth due to the development of advanced components that expand the application areas of these elevators. Hydraulic elevators, a type of vertical transportation, are known for their durability and energy efficiency. They use hydraulic fluid, an inert substance, to lift the elevator cab through the use of an electronic pump, cylinder, piston, and pressure. Hydraulic elevators are commonly used in low-rise applications and offer convenience for transporting goods and heavy loads. Manufacturers are focusing on developing machine room-less applications and space-saving designs to cater to the needs of building owners. Hydraulic elevators are ideal for residential and commercial buildings, regardless of their height or floor height.

- Additionally, these elevators provide safe lifting capabilities, making them essential for reducing injuries and ensuring safe working conditions. HILA (Hydraulic In-Line Traction) technology is a recent innovation that combines the benefits of both hydraulic and traction elevators. Developed by Linkoping University and SAAB AB, HILA features a two-stroke cylinder mechanism with two engaging and disengaging clamping mechanisms. The motion of the two cylinders is linked to each other with the clamping mechanism, providing reliable and safe vertical movement. The hydraulic compressor is an essential component of hydraulic elevators, and manufacturers are focusing on energy efficiency and reducing maintenance costs.

- Additionally, Air compressors are being replaced with more efficient hydraulic systems, ensuring safe and efficient operation. Hydraulic elevators are also used in various industries for transporting heavy goods, such as table lifts, vehicle lifts, dock lifts, and positioning work material. In summary, the market is expected to grow due to the development of advanced technologies and the increasing demand for safe and efficient vertical transportation. Manufacturers are focusing on energy efficiency, durability, and reliability to cater to the needs of building owners and ensure safe working conditions. HILA technology is a recent innovation that combines the benefits of both hydraulic and traction elevators, providing a reliable and efficient solution for various applications.

What challenges does the Hydraulic Elevators Industry face during its growth?

An increase in preference for substitute products is a key challenge affecting the industry growth.

- Hydraulic elevators, a type of vertical transportation, have been a long-standing solution for building vertical movement. However, their use is increasingly being replaced by traction elevators in various applications due to several reasons. Hydraulic elevators utilize hydraulic fluid, an incompressible fluid, to lift the elevator cab through the use of a cylinder, piston, and an electronic pump. The jack module, which can be an in-ground jack or a twinpost jack, provides the necessary pressure to lift the cab. In contrast, modern traction elevators, including machine room-less (MRL) designs, do not require an overhead machine room, making them more space-saving and convenient for building owners. Hydraulic elevators, on the other hand, have limitations in terms of building height, floor height, and energy efficiency. Their energy consumption is higher than traction elevators due to the hydraulic compressor and air compressors used.

- Moreover, safety is a critical factor in vertical transportation. Hydraulic elevators have safety codes to ensure safe lifting, but they are more susceptible to extreme pressure, which could lead to serious injuries such as puncturing the skin. In contrast, traction elevators offer reliable and safe lifting solutions, making them a preferred choice for both residential and commercial buildings. The demand for traction elevators, particularly MRL designs, is increasing due to their energy efficiency, durability, and convenience. They consume significantly less energy than hydraulic elevators, making them a more eco-friendly option. Additionally, their space-saving designs and machine room-less applications make them ideal for various applications, including transporting goods, heavy loads, positioning work material, trucks, and vehicle lifts. In summary, while hydraulic elevators have their place In the market, the trend is shifting towards traction elevators due to their energy efficiency, durability, and convenience. Building owners and operators are recognizing the benefits of traction elevators, leading to a significant increase in demand for these reliable lifts.

Exclusive Customer Landscape

The hydraulic elevators market forecasting report includes the adoption lifecycle of the market, covering from the innovator's stage to the laggard's stage. It focuses on adoption rates in different regions based on penetration. Furthermore, the hydraulic elevators market report also includes key purchase criteria and drivers of price sensitivity to help companies evaluate and develop their market growth analysis strategies.

Customer Landscape

Key Companies & Market Insights

Companies are implementing various strategies, such as strategic alliances, hydraulic elevators market forecast, partnerships, mergers and acquisitions, geographical expansion, and product/service launches, to enhance their presence In the industry. The industry research and growth report includes detailed analyses of the competitive landscape of the market and information about key companies, including:

- Advance Lifts Inc.

- Bonsdag Industries Pvt. Ltd.

- Bucher Industries AG

- CIRCOR International Inc.

- Custom Elevator Manufacturing Inc.

- Delta Elevator Co. Ltd.

- GMV Polska Sp. z o.o.

- Kleemann Hellas S.A.

- Mahe Lifts

- Mitsubishi Electric Corp.

- Modern Elevator Innovations

- Morris Vermaport Ltd.

- Otis Worldwide Corp.

- PFlow Industries Inc.

- Schindler Holding Ltd.

- Schumacher Elevator Co.

- thyssenkrupp AG

- Vantage Elevation LLC

- VRS Elevators Pvt. Ltd.

- Waupaca Elevator Co.

Qualitative and quantitative analysis of companies has been conducted to help clients understand the wider business environment as well as the strengths and weaknesses of key industry players. Data is qualitatively analyzed to categorize companies as pure play, category-focused, industry-focused, and diversified; it is quantitatively analyzed to categorize companies as dominant, leading, strong, tentative, and weak.

Research Analyst Overview

Hydraulic elevators represent a significant segment of the vertical transportation market, providing efficient and reliable solutions for both residential and commercial applications. These systems utilize hydraulic fluids to move elevator cabs up and down, offering several advantages over other types of elevators. Energy efficiency is a crucial factor In the selection of vertical transportation systems. Hydraulic elevators, with their energy-dense hydraulic fluid, offer impressive energy efficiency. The electronic pump and cylinder components work in harmony, converting electrical energy into hydraulic pressure, which is then used to lift the elevator cab. Durability is another essential aspect of hydraulic elevators. The design of these systems, featuring pistons and cylinders, ensures long-lasting performance. Building owners appreciate the longevity of hydraulic elevators, as they require minimal maintenance and offer reliable service for many years.

Additionally, safety is paramount In the design and operation of hydraulic elevators. Stringent safety codes govern the installation and maintenance of these systems, ensuring safe lifting capabilities for transporting goods and heavy loads. In-ground jacks and jack modules provide a stable foundation, while above-ground systems offer space-saving designs for low-rise applications. The versatility of hydraulic elevators extends to various industries and applications. In residential buildings, these systems offer convenience and reliability, while commercial buildings benefit from their ability to transport heavy loads and large volumes of people. Machine room-less applications further reduce the footprint of hydraulic elevators, making them an attractive choice for modern buildings. Quality and reliability are essential factors for building owners when selecting vertical transportation systems. Hydraulic elevators deliver on both fronts, providing consistent performance and long-lasting durability. The hydraulic compressor, a vital component, ensures a steady supply of hydraulic pressure, ensuring safe and efficient elevator operation. The environment is increasingly becoming a critical consideration In the design and implementation of vertical transportation systems. Hydraulic elevators offer energy efficiency and a smaller environmental footprint compared to traction elevators.

Moroever, the use of air compressors in hydraulic systems can be optimized for energy efficiency and reduced emissions. Transporting goods and heavy loads is a common application for hydraulic elevators. These systems offer the capability to lift significant weights, making them an ideal choice for industries such as construction, manufacturing, and logistics. Table lifts, dock lifts, and mobile hydraulic lifts are just a few examples of specialized hydraulic elevator applications designed for transporting goods and positioning work materials. Safety is a top priority In the operation of hydraulic elevators. Proper installation, maintenance, and adherence to safety codes are essential to reducing the risk of serious injury. Extreme pressure and the potential for puncturing skin are concerns when working with hydraulic systems. However, with proper training and adherence to safety guidelines, these risks can be effectively managed. In summary, hydraulic elevators offer a versatile and reliable vertical transportation solution, catering to various industries and applications. Their energy efficiency, durability, and safety features make them an attractive choice for building owners and operators. With continuous advancements in technology and design, hydraulic elevators will continue to play a significant role In the vertical transportation market.

|

Hydraulic Elevators Market Scope |

|

|

Report Coverage |

Details |

|

Page number |

147 |

|

Base year |

2023 |

|

Historic period |

2018-2022 |

|

Forecast period |

2024-2028 |

|

Growth momentum & CAGR |

Accelerate at a CAGR of 1.4% |

|

Market growth 2024-2028 |

USD 595.1 million |

|

Market structure |

Fragmented |

|

YoY growth 2023-2024(%) |

1.3 |

|

Key countries |

China, Germany, US, UK, and India |

|

Competitive landscape |

Leading Companies, Market Positioning of Companies, Competitive Strategies, and Industry Risks |

What are the Key Data Covered in this Hydraulic Elevators Market Research and Growth Report?

- CAGR of the Hydraulic Elevators industry during the forecast period

- Detailed information on factors that will drive the Hydraulic Elevators growth and forecasting between 2024 and 2028

- Precise estimation of the size of the market and its contribution of the industry in focus to the parent market

- Accurate predictions about upcoming growth and trends and changes in consumer behaviour

- Growth of the market across APAC, Europe, North America, Middle East and Africa, and South America

- Thorough analysis of the market's competitive landscape and detailed information about companies

- Comprehensive analysis of factors that will challenge the hydraulic elevators market growth of industry companies

We can help! Our analysts can customize this hydraulic elevators market research report to meet your requirements.