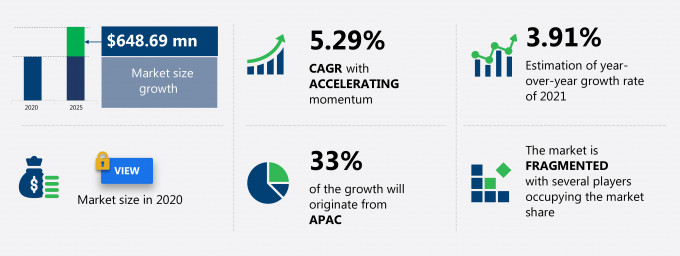

The industrial automation in food safety and inspection market share is expected to increase by USD 648.69 million from 2020 to 2025, and the market’s growth momentum will accelerate at a CAGR of 5.29%.

This industrial automation in food safety and inspection market research report provides valuable insights on the post COVID-19 impact on the market, which will help companies evaluate their business approaches. Furthermore, this report extensively covers industrial automation in food safety and inspection market segmentations by product (machine vision systems, X-ray inspection systems, metal detection systems, and checkweighing systems) and geography (Europe, APAC, North America, South America, and MEA). The industrial automation in food safety and inspection market report also offers information on several market vendors, including Advantech Co. Ltd., Clarke Solutions LLC, Cognex Corp., Illinois Tool Works Inc., Inspection Systems Pty Ltd., John Bean Technologies Corp., Mettler Toledo International Inc., Peco InspX, Teledyne Technologies Inc., and Thermo Fisher Scientific Inc. among others.

What will the Industrial Automation In Food Safety And Inspection Market Size be During the Forecast Period?

Download the Free Report Sample to Unlock the Industrial Automation in Food Safety and Inspection Market Size for the Forecast Period and Other Important Statistics

Industrial Automation In Food Safety And Inspection Market: Key Drivers, Trends, and Challenges

The significant cost savings in operations due to process control is notably driving the industrial automation in food safety and inspection market growth, although factors such as volatility in prices of raw materials may impede market growth. Our research analysts have studied the historical data and deduced the key market drivers and the COVID-19 pandemic impact on the industrial automation in food safety and inspection industry. The holistic analysis of the drivers will help in deducing end goals and refining marketing strategies to gain a competitive edge.

Key Industrial Automation In Food Safety And Inspection Market Driver

The significant cost savings in operations due to process control is a major factor driving the global industrial automation market in food safety and inspection market share growth. Machine vision systems are employed in the initial stages of production. With the help of machine vision systems, defective components are removed instantly from the process. At times, the removed parts can be reintroduced into the production process. This saves materials. Defective parts do not continue to the subsequent manufacturing phase; and, therefore, do not lead to further costs. The use of machine vision systems in the food and beverages industry helps in reducing labor costs as well as avoiding costs related to any corrective action. With the rise in the labor cost in the US and China, it is becoming difficult for manufacturers to control the cost that may later affect the competitive strategy of a company. The use of machine vision systems helps in the automatic capturing of data as well as reducing defects in products and processes. With automation, there is a minimal requirement for human intervention. This, in turn, reduces the labor cost. Due to such factors, the demand for the market will continue to increase during the forecast period.

Key Industrial Automation In Food Safety And Inspection Market Trend

The MDX technology for food inspection systems is another factor supporting the global industrial automation market in food safety and inspection market share growth. The Material Discrimination X-ray technology (MDX) is an upgraded X-ray technology. Like traditional X-ray systems, MDX involves the use of a generator to project an X-ray beam onto a detector and pass a product through the beam. The difference between X-ray inspection and MDX is the use of two energy spectrums to discriminate between high- and low-channel X-rays, as well as a dual-layer detector by MDX. MDX technology, in general, eliminates most of the effect of product thickness variations and leaves an image that shows a density difference based on chemical composition. Food products are mostly organic and usually contain water. Chemically, food products consist primarily of hydrogen, carbon, and oxygen. Any foreign body containing an element of a higher atomic number than carbon or oxygen can be easily detected by MDX technology. Foreign bodies that are visible in an X-ray image can be detected using traditional X-ray methods, but many foreign bodies that are not readily visible in an X-ray image can be detected with MDX technology. Therefore, the market will continue to grow during the forecast period.

Key Industrial Automation In Food Safety And Inspection Market Challenge

The volatility in prices of raw materials will be a major challenge for the global industrial automation market in food safety and inspection market share growth during the forecast period. Instability in the price of raw materials affects the production of food safety and inspection systems. For instance, the price of steel can be influenced by various factors, including natural disasters and the global economy. Several key vendors prefer long-term contracts with suppliers to reduce the impact of price fluctuations of raw materials. However, long-term contracts with suppliers are not feasible for small vendors due to their low production volume. Stainless steel, iron, bronze, and copper are the most commonly used raw materials for manufacturing food safety and inspection systems. The prices of raw materials depend on their production and availability and the inflation of the economy. Variations in these parameters affect the manufacturing of food safety and inspection systems as they could increase or decrease the cost of production, and therefore hamper the growth of the market.

This industrial automation in food safety and inspection market analysis report also provides detailed information on other upcoming trends and challenges that will have a far-reaching effect on the market growth. The actionable insights on the trends and challenges will help companies evaluate and develop growth strategies for 2021-2025.

Parent Market Analysis

Technavio categorizes the global industrial automation market in food safety and inspection market as a part of the global industrial machinery market. Our research report has extensively covered external factors influencing the parent market growth potential in the coming years, which will determine the levels of growth of the industrial automation market in food safety and inspection market during the forecast period.

Who are the Major Industrial Automation In Food Safety And Inspection Market Vendors?

The report analyzes the market’s competitive landscape and offers information on several market vendors, including:

- Advantech Co. Ltd.

- Clarke Solutions LLC

- Cognex Corp.

- Illinois Tool Works Inc.

- Inspection Systems Pty Ltd.

- John Bean Technologies Corp.

- Mettler Toledo International Inc.

- Peco InspX

- Teledyne Technologies Inc.

- Thermo Fisher Scientific Inc.

This statistical study of the industrial automation market in food safety and inspection market encompasses successful business strategies deployed by the key vendors. The industrial automation market in food safety and inspection market is fragmented and the vendors are deploying organic and inorganic growth strategies to compete in the market.

Product Insights and News

- Advantech Co. Ltd.- The company offers solutions in industrial automation by delivering flexible and efficient ways for food and beverage manufacturers to fulfill high demand in product variability while maintaining the safety of the food and supply, under the brand names of Rugged Industry 4.0, WebOP 2000T, UNO 1251G and SRP FPV240.

To make the most of the opportunities and recover from post COVID-19 impact, market vendors should focus more on the growth prospects in the fast-growing segments, while maintaining their positions in the slow-growing segments.

The industrial automation in food safety and inspection market forecast report offers in-depth insights into key vendor profiles. The profiles include information on the production, sustainability, and prospects of the leading companies.

Industrial Automation In Food Safety And Inspection Market Value Chain Analysis

Our report provides extensive information on the value chain analysis for the industrial automation in food safety and inspection market, which vendors can leverage to gain a competitive advantage during the forecast period. The end-to-end understanding of the value chain is essential in profit margin optimization and evaluation of business strategies. The data available in our value chain analysis segment can help vendors drive costs and enhance customer services during the forecast period.

The value chain of global industrial machinery market includes the following core components:

- Inputs

- Inbound logistics

- Operations

- Outbound logistics

- Marketing and sales

- Service

- Support activities

- Innovation

The report has further elucidated on other innovative approaches being followed by manufacturers to ensure a sustainable market presence.

Which are the Key Regions for Industrial Automation In Food Safety And Inspection Market?

For more insights on the market share of various regions Request for a FREE sample now!

33% of the market’s growth will originate from APAC during the forecast period. US, China, UK, Japan, and Germany are the key markets for industrial automation market in food safety and inspection market in APAC. Market growth in this region will be faster than the growth of the market in regions.

The expanding population and the improving per capita incomes of people have increased the consumption of processed and convenience food, which will facilitate the industrial automation market in food safety and inspection market growth in APAC over the forecast period. This market research report entails detailed information on the competitive intelligence, marketing gaps, and regional opportunities in store for vendors, which will assist in creating efficient business plans.

What are the Revenue-generating Product Segments in the Industrial Automation In Food Safety And Inspection Market?

To gain further insights on the market contribution of various segments Request for a FREE sample

The industrial automation market in food safety and inspection market share growth by the machine vision systems segment will be significant during the forecast period. Factors such as concerns of food manufacturers to improve the traceability of their products within the food chain and supply chain, growing need for food safety across geographies, increased adoption of robotics in the food and beverages industry, and growing applications of machine vision technology in defect recognition, lenience monitoring, quality inspection, and component monitoring are expected to drive the market during the forecast period. Moreover, applications of 2D and 3D imaging, smart cameras, and vision-guided robots will further enhance the market's potential.

This report provides an accurate prediction of the contribution of all the segments to the growth of the industrial automation in food safety and inspection market size and actionable market insights on post COVID-19 impact on each segment.

|

Industrial Automation In Food Safety And Inspection Market Scope |

|

|

Report Coverage |

Details |

|

Page number |

120 |

|

Base year |

2020 |

|

Forecast period |

2021-2025 |

|

Growth momentum & CAGR |

Accelerate at a CAGR of 5.29% |

|

Market growth 2021-2025 |

$ 648.69 million |

|

Market structure |

Fragmented |

|

YoY growth (%) |

3.91 |

|

Regional analysis |

Europe, APAC, North America, South America, and MEA |

|

Performing market contribution |

APAC at 33% |

|

Key consumer countries |

US, China, UK, Japan, and Germany |

|

Competitive landscape |

Leading companies, Competitive strategies, Consumer engagement scope |

|

Key companies profiled |

Advantech Co. Ltd., Clarke Solutions LLC, Cognex Corp., Illinois Tool Works Inc., Inspection Systems Pty Ltd., John Bean Technologies Corp., Mettler Toledo International Inc., Peco InspX, Teledyne Technologies Inc., and Thermo Fisher Scientific Inc. |

|

Market dynamics |

Parent market analysis, Market growth inducers and obstacles, Fast-growing and slow-growing segment analysis, COVID 19 impact and recovery analysis and future consumer dynamics, Market condition analysis for forecast period |

|

Customization purview |

If our report has not included the data that you are looking for, you can reach out to our analysts and get segments customized. |

What are the Key Data Covered in this Industrial Automation In Food Safety And Inspection Market Report?

- CAGR of the market during the forecast period 2021-2025

- Detailed information on factors that will drive industrial automation in food safety and inspection market growth during the next five years

- Precise estimation of the industrial automation in food safety and inspection market size and its contribution to the parent market

- Accurate predictions on upcoming trends and changes in consumer behavior

- The growth of the industrial automation in food safety and inspection industry across Europe, APAC, North America, South America, and MEA

- A thorough analysis of the market’s competitive landscape and detailed information on vendors

- Comprehensive details of factors that will challenge the growth of industrial automation in food safety and inspection market vendors

We can help! Our analysts can customize this report to meet your requirements. Get in touch