Industrial Mixers Market Size 2025-2029

The industrial mixers market size is forecast to increase by USD 1.05 billion at a CAGR of 6% between 2024 and 2029.

- The market is experiencing significant growth, driven primarily by the increasing demand for mixers in sanitary applications. This trend is being fueled by the food and beverage industry's focus on producing high-quality products with consistent taste and texture. Another key driver is the adoption of Programmable Logic Controllers (PLCs) for mixer automation, enabling improved process control and efficiency. However, the market is not without challenges, as raw material price fluctuations pose a significant threat to profitability. Producers must closely monitor raw material costs and explore alternative sourcing strategies to mitigate these risks.

- To capitalize on market opportunities and navigate challenges effectively, companies should focus on innovation, cost reduction, and operational excellence. By investing in advanced technologies, such as energy-efficient mixers and smart sensors, and optimizing their supply chains, manufacturers can differentiate themselves in a competitive landscape and maintain a strong market position. Additionally, the integration of advanced sensors into mixers is improving process control and monitoring, leading to more accurate results. The use of aluminum in the construction of mixers is also gaining traction due to its lightweight, durable, and corrosion-resistant properties, further enhancing the performance and longevity of the equipment.

What will be the Size of the Industrial Mixers Market during the forecast period?

- The industrial mixing market encompasses a diverse range of applications, including food, plastic, pharmaceutical, and cosmetic industries, among others. This market is driven by the increasing demand for efficient and effective mixing processes to meet stringent hygiene standards and optimize performance. Key trends include the adoption of energy-efficient mixing technologies, advanced mixing validation protocols, and mixing simulation software for process optimization. The market is characterized by a high level of activity, with a significant focus on improving mixing chamber design, material flow, and process control. Liquid handling and powder handling applications are particularly prominent, with a growing emphasis on solids handling and rubber, ceramic, and concrete mixing applications. These mixers cater to diverse requirements, including those for high-viscosity fluids, abrasives, toxic materials, and corrosives.

- Energy efficiency, mixer maintenance, and troubleshooting are also critical factors, as industries seek to minimize downtime and reduce costs. The market is expected to continue growing, driven by the increasing demand for high-performance mixing systems and the need for process safety and cleaning validation in various industries. Overall, the industrial mixing market is a dynamic and innovative sector, with ongoing advancements in technology and application-specific solutions. Mixing, blending, homogenization processes are crucial in the production of packaged foods, cosmetics, and chemicals.

How is this Industrial Mixers Industry segmented?

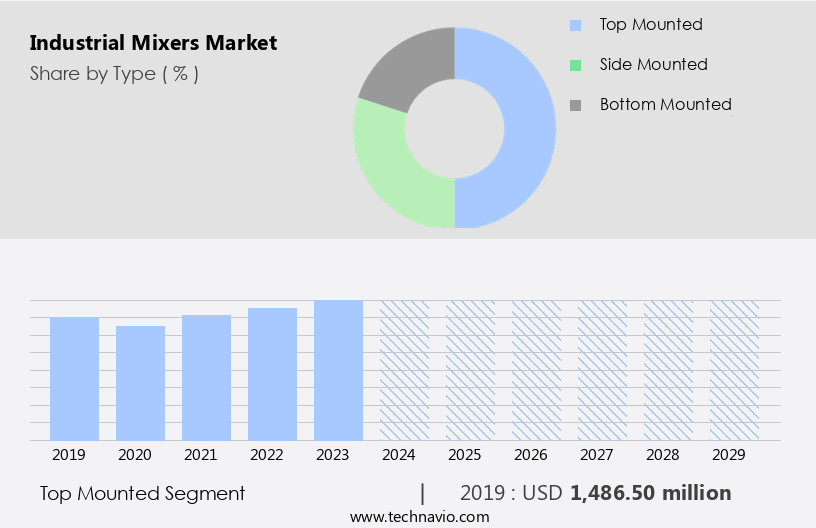

The industrial mixers industry research report provides comprehensive data (region-wise segment analysis), with forecasts and estimates in "USD million" for the period 2025-2029, as well as historical data from 2019-2023 for the following segments.

- Type

- Top mounted

- Side mounted

- Bottom mounted

- End-user

- Chemical industry

- Food and beverage industry

- Pharmaceutical industry

- Others

- Technology

- High shear mixers

- Static mixers

- Dynamic mixers

- Planetary mixers

- Others

- Geography

- APAC

- Australia

- China

- India

- Japan

- South Korea

- North America

- US

- Canada

- Europe

- France

- Germany

- Italy

- South America

- Middle East and Africa

- APAC

By Type Insights

The top mounted segment is estimated to witness significant growth during the forecast period Industrial mixers, a crucial component in various manufacturing processes, are designed to ensure optimal mixing uniformity and efficiency. Vertical mixers, also known as top-mounted mixers, are a popular choice due to their versatility and ability to handle a wide range of densities and viscosities. These mixers, which feature a shaft whose end is positioned at the bottom of the tank, are essential in industries such as chemicals, composites, batteries, adhesives, and coatings. Manufacturers, like ROSS in the US, continue to innovate and introduce advanced mixing technologies. For instance, in December 2024, ROSS launched the FDA-600 Dual Shaft Mixer, designed to cater to diverse industrial applications. High-performance mixing devices are utilized in wastewater treatment and pulp mills to handle high-viscosity fluids, abrasives, toxic materials, and corrosives.

This mixer boasts wear resistance, vacuum mixing, and mixing automation capabilities, making it suitable for high viscosity and corrosive materials. Additionally, it offers pressure control, temperature control, and data logging for process optimization and mixing validation. Mixing techniques encompass various methods, including high shear mixing, dispersion mixing, suspension mixing, and emulsion mixing. High shear mixers, for example, are used to reduce particle size and improve product quality, while dispersion mixers ensure uniform distribution of solids in liquids. Inline mixing and continuous mixing systems are essential for large-scale production, ensuring energy consumption efficiency and minimizing mixing time. Mixing equipment must also adhere to stringent industry regulations, such as FDA regulations in the pharmaceutical sector. Steel is a primary material used in the fabrication of mixers, while other raw materials such as copper, stainless steel, cast iron, aluminum, brass, and bronze are also utilized.

Mixing optimization and simulation techniques are employed to enhance productivity and improve product quality. Other essential mixing technologies include fluid bed mixers, ribbon blenders, paddle mixers, and double planetary mixers. Material handling and material compatibility are crucial considerations when selecting the appropriate mixing equipment. Remote monitoring and explosion proof features are essential safety features in industrial mixing applications. Mixing capacity, mixing efficiency, and mixing control are critical factors in the selection and design of industrial mixers. Mixing techniques and technologies continue to evolve, with a focus on improving process optimization, reducing energy consumption, and enhancing product quality.

Get a glance at the market report of share of various segments Request Free Sample

The Top mounted segment was valued at USD 1.49 billion in 2019 and showed a gradual increase during the forecast period.

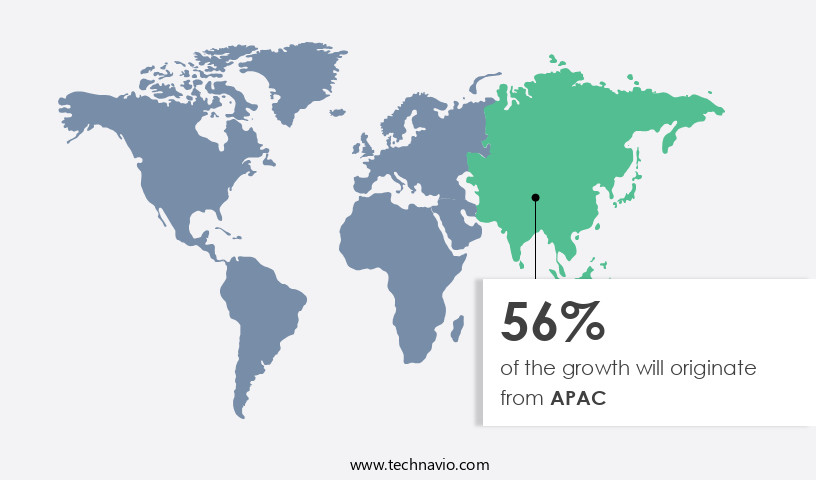

Regional Analysis

APAC is estimated to contribute 56% to the growth of the global market during the forecast period.Technavio's analysts have elaborately explained the regional trends and drivers that shape the market during the forecast period.

For more insights on the market size of various regions, Request Free Sample

The Industrial Mixer Market encompasses various mixing technologies and techniques used to achieve optimal mixing uniformity in a wide range of industries. Key market drivers include the need for process optimization, material compatibility, and wear resistance. Vacuum mixing and inline mixing are essential for applications requiring high levels of mixing efficiency and particle size reduction. High shear mixers are suitable for high viscosity materials, while vertical and horizontal mixers cater to different volume requirements. Mixing automation and temperature control are crucial for ensuring consistent product quality and compliance with regulations, particularly in industries such as chemical processing and pharmaceuticals.

Data logging and remote monitoring enable real-time process optimization and mixing validation. Corrosion resistance and pressure control are essential features for specific applications. Market trends include the adoption of continuous mixing systems and the integration of mixing technologies with material handling systems for improved energy consumption and overall process efficiency. Dispersion mixing and suspension mixing are essential for producing homogeneous mixtures in various industries, including food processing and FDA-regulated sectors. The global chemical industry, with significant contributions from Japan and China, is a significant market for industrial mixers. Rapidly growing economies in Asia Pacific (APAC) are driving the demand for chemicals and food products, thereby fueling the need for advanced mixing solutions.

Key applications include liquid mixing, powder mixing, and solid mixing, among others. In summary, the Industrial Mixer Market is a dynamic and evolving industry, driven by the need for improved mixing efficiency, material compatibility, and process optimization. The market caters to various industries and applications, with a focus on ensuring product quality, energy efficiency, and regulatory compliance.

Market Dynamics

Our researchers analyzed the data with 2024 as the base year, along with the key drivers, trends, and challenges. A holistic analysis of drivers will help companies refine their marketing strategies to gain a competitive advantage.

What are the key market drivers leading to the rise in the adoption of Industrial Mixers Industry?

- Growing demand for mixers for sanitary applications is the key driver of the market. In the realms of food and pharmaceutical manufacturing, stringent sanitation and hygiene regulations are non-negotiable. From sourcing raw materials to producing the final product, these industries prioritize maintaining a pristine environment. Industrial mixers, a crucial component of the manufacturing process, must adhere to these standards. To cater to this demand, companies are introducing high-sanitation mixers. For instance, ALFA LAVAL's Magnetic Mixer UltraPure operates at low rpm during cleaning, ensuring thorough and efficient sanitization.

- This low-speed rotation results in a more comprehensive cleaning process, ultimately contributing to the production of superior quality goods.

What are the market trends shaping the Industrial Mixers Industry?

- PLC-based control for mixers is the upcoming market trend. Industrial mixers have become essential components in manufacturing industries, as manufacturers seek to ensure consistent product quality with high precision. Traditional manual mixing methods are being replaced with automated mixing systems, driven by Programmable Logic Controllers (PLCs). Manual mixing is time-consuming and prone to errors, whereas automated mixing, integrated with PLCs, significantly reduces error rates and provides consistent results. The increasing adoption of automation in industries is a major factor driving the integration of PLCs with industrial equipment, such as mixers.

- For instance, consider a process involving the mixing of two fluids to create a new one. By automating this process with a PLC-controlled mixer, manufacturers can improve efficiency, reduce errors, and ensure consistent product quality. This trend is expected to continue, as industries increasingly embrace automation to enhance productivity and maintain competitive edges.

What challenges does the Industrial Mixers Industry face during its growth?

- Fluctuation in raw material prices is a key challenge affecting the industry growth. The cost of raw materials significantly influences the selling price and profit margin of industrial mixers. Primarily, steel is the major component used in their construction, but other materials such as copper, stainless steel, cast iron, aluminum, brass, and bronze are also utilized. These raw materials are essential for various industrial applications, implying that shifts in demand from other sectors can impact their prices for mixer manufacturers.

- In mixing processes, specialized materials are necessary to prevent corrosion and contaminant growth. The price fluctuations of these raw materials can significantly affect the overall market dynamics.

Exclusive Customer Landscape

The industrial mixers market forecasting report includes the adoption lifecycle of the market, covering from the innovator's stage to the laggard's stage. It focuses on adoption rates in different regions based on penetration. Furthermore, the industrial mixers market report also includes key purchase criteria and drivers of price sensitivity to help companies evaluate and develop their market growth analysis strategies.

Customer Landscape

Key Companies & Market Insights

Companies are implementing various strategies, such as strategic alliances, industrial mixers market forecast, partnerships, mergers and acquisitions, geographical expansion, and product/service launches, to enhance their presence in the industry.

ACUMIX Inc. - The company specializes in providing a range of industrial mixers, including bung-mounted, economy gear-driven portable, and top-entering models. These mixers cater to various application requirements, ensuring efficient and effective processing solutions.

The industry research and growth report includes detailed analyses of the competitive landscape of the market and information about key companies, including:

- ACUMIX Inc.

- Admix Inc.

- Alfa Laval AB

- amixon GmbH

- Ebara Corp.

- EKATO HOLDING GmbH

- GEA Group AG

- Heilig Mixing Technology B.V.

- ILC Dover LP

- JWB Systems Inc.

- Kady International

- Lindor Products BV

- NOV Inc.

- Paul O. Abbe

- Satake Technologies Sdn Bhd

- Silverson Machines Inc.

- SPX FLOW Inc.

- Statiflo Group

- Sulzer Ltd.

- Xylem Inc.

Qualitative and quantitative analysis of companies has been conducted to help clients understand the wider business environment as well as the strengths and weaknesses of key industry players. Data is qualitatively analyzed to categorize companies as pure play, category-focused, industry-focused, and diversified; it is quantitatively analyzed to categorize companies as dominant, leading, strong, tentative, and weak.

Research Analyst Overview

Industrial mixers play a crucial role in various manufacturing processes, ensuring the uniform blend of different materials to produce high-quality products. This market encompasses a wide range of mixing technologies and equipment, each designed to address specific process requirements. One essential consideration in the industrial mixing landscape is wear resistance. This attribute is crucial in applications where the materials being mixed exhibit abrasive properties, leading to increased equipment downtime and maintenance costs. To mitigate this issue, manufacturers have developed mixers with materials of construction, such as ceramic linings or hardened steel, to enhance wear resistance and prolong the life of the equipment.

Another essential aspect of industrial mixing is vacuum mixing. This technique is employed in applications where the presence of air in the mixture can negatively impact the final product's quality. Vacuum mixing systems create a vacuum environment within the mixer, preventing air from entering the mixture, and ensuring better mixing uniformity. Mixing automation is another trend gaining traction in the industrial mixing market. Automated mixing systems offer numerous benefits, including increased efficiency, improved product consistency, and reduced labor costs. These systems can be integrated with other process control systems, enabling real-time monitoring and adjustments to optimize the mixing process.

Mixing uniformity is a critical factor in various industries, including chemical processing, food processing, and pharmaceuticals. Achieving uniform mixing is essential to ensure consistent product quality and prevent batch-to-batch variations. High shear mixers and double planetary mixers are popular choices for applications requiring high shear forces to achieve uniform mixing. Material compatibility is another essential factor in the industrial mixing market. Different materials require specific mixing conditions and equipment to prevent degradation or damage. For instance, high viscosity materials may require specialized mixers, such as ribbon blenders or fluid bed mixers, to ensure proper mixing and prevent equipment damage. StartFragment The Avocado Market sees innovative mixing system integration improving processing. Advances in mixing process control, efficient mixing software, precise mixing modeling, effective mixing optimization strategies, focus on energy efficient mixing, assessing mixing performance metrics aid production quality. Processes like mixer calibration, solving issues through mixer troubleshooting, necessary mixer repair streamline operations. Diverse applications like pharmaceutical mixing applications, food mixing applications, chemical mixing applications, cosmetic mixing applications, paint mixing applications, ceramic mixing applications, plastic mixing applications, rubber mixing applications contribute to market diversity. Mixing innovations significantly impact avocado product development, enhancing distribution and sustainability efforts. The market adapts to modern technologies, leveraging advanced mixing methods to cater to growing demand efficiently and sustainably.

EndFragment Pressure control is a critical aspect of industrial mixing, particularly in applications involving the mixing of gases or viscous liquids. Proper pressure control ensures efficient mixing and prevents equipment damage. Vertical mixers and continuous mixers are popular choices for applications requiring pressure control. Process optimization is a key focus area in the industrial mixing market. Mixing simulation and optimization techniques enable manufacturers to optimize their mixing processes, reducing energy consumption and improving overall efficiency. Data logging and remote monitoring systems can provide valuable insights into mixing processes, enabling real-time adjustments and improvements. The industrial mixing market is a dynamic and diverse landscape, encompassing a wide range of technologies and equipment designed to meet specific process requirements.

Factors such as wear resistance, vacuum mixing, mixing automation, mixing uniformity, material compatibility, pressure control, and process optimization are essential considerations in the industrial mixing market. By focusing on these factors, manufacturers can optimize their mixing processes, improve product quality, and reduce costs.

|

Market Scope |

|

|

Report Coverage |

Details |

|

Page number |

231 |

|

Base year |

2024 |

|

Historic period |

2019-2023 |

|

Forecast period |

2025-2029 |

|

Growth momentum & CAGR |

Accelerate at a CAGR of 6% |

|

Market growth 2025-2029 |

USD 1048.2 million |

|

Market structure |

Fragmented |

|

YoY growth 2024-2025(%) |

5.5 |

|

Key countries |

US, China, India, Germany, Canada, France, Japan, Italy, Australia, and South Korea |

|

Competitive landscape |

Leading Companies, Market Positioning of Companies, Competitive Strategies, and Industry Risks |

What are the Key Data Covered in this Industrial Mixers Market Research and Growth Report?

- CAGR of the Industrial Mixers industry during the forecast period

- Detailed information on factors that will drive the growth and forecasting between 2025 and 2029

- Precise estimation of the size of the market and its contribution of the industry in focus to the parent market

- Accurate predictions about upcoming growth and trends and changes in consumer behaviour

- Growth of the market across APAC, North America, Europe, South America, and Middle East and Africa

- Thorough analysis of the market's competitive landscape and detailed information about companies

- Comprehensive analysis of factors that will challenge the industrial mixers market growth of industry companies

We can help! Our analysts can customize this industrial mixers market research report to meet your requirements.