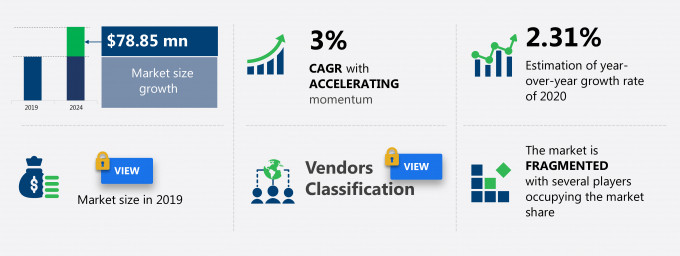

The laser cutting machine market share in US is expected to increase by USD 78.85 million from 2019 to 2024, and the market’s growth momentum will accelerate at a CAGR of 3%.

This laser cutting machine market in US research report provides valuable insights on the post COVID-19 impact on the market, which will help companies evaluate their business approaches. Furthermore, this report extensively covers laser cutting machine market segmentation in US by product (fiber, solid-state, diode, and others) and end-user (automotive, aerospace and defense, electrical and electronics, industrial machinery, and others). The laser cutting machine market in US report also offers information on several market vendors, including Coherent Inc., Conzzeta Management AG, DMG MORI Co. Ltd., IPG Photonics Corp., Koike Aronson Inc., Laserline GmbH, Mitsubishi Electric Corp., TRUMPF GmbH + Co. KG, and Wuhan HGLaser Engineering Co. Ltd. among others.

What will the Laser Cutting Machine Market Size in US be During the Forecast Period?

Download the Free Report Sample to Unlock the Laser Cutting Machine Market Size in US for the Forecast Period and Other Important Statistics

Laser Cutting Machine Market in US: Key Drivers, Trends, and Challenges

The increasing focus on automating metal cutting process is notably driving the laser cutting machine market growth in US, although factors such as availability of alternate machine tools for metal cutting application may impede the market growth. Our research analysts have studied the historical data and deduced the key market drivers and the COVID-19 pandemic impact on the laser cutting machine industry in US. The holistic analysis of the drivers will help in deducing end goals and refining marketing strategies to gain a competitive edge.

Key Laser Cutting Machine Market Driver in US

One of the key factors driving growth in the laser cutting machine market in US is the increasing focus on automating metal cutting process. The metal cutting process is mechanized, and various steps are being initiated by vendors to produce automated cutting machines. The increasing need to meet market demands for optimized flexibility and personalization in terms of product design and proportions in the cutting process has enabled integration across all production steps. This integration is now prominent among all functions within and outside a company floor. Individual standalone laser cutting machines can now be integrated into the production flow using automated software; this enables large industrial plants to partially shift toward unmanned production processes, which ensures high performance with a reduction in human resource requirement. The application of robotics in the metalworking industry ranges from applications such as cutting, cleaning of various materials, marking, and drilling. The whole process is performed by high-power lasers capable of vaporizing a range of materials, from steel to plastic, with a high level of precision. The versatility of these machines enables manufacturers to cut these materials and develop products and components with complex geometry. The flexibility in the usage of automated solutions and the standardization of laser cutting machines have increased the demand for automated laser cutting machines among end-user industries.

Key Laser Cutting Machine Market Trend in US

The rising digitalization in manufacturing processes is a laser cutting machine market in US trend that is expected to have a positive impact in the coming years. Through the use of the industrial Internet of things (IoT), vendors are focusing on developing a connected device and streamlining the complete manufacturing process. IoT comprises a network of physical objects with an IP address, which allows it to connect to the internet; it also includes communication between these objects and other internet-enabled devices. A diverse range of industrial devices are equipped with embedded technology and are a part of the industrial IoT network, such as motors, drives, and sensors, which are used in manufacturing processes. These devices may use other devices or hardware, such as smartphones, as their gateway to the internet to send data to cloud computing servers. The data received by the servers are then aggregated and analyzed. Increasing digitalization has helped the laser cutting industry to become more competitive in the US. Digitalization enables real-time connectivity with the user, eliminates waste during manufacturing operation by optimization, enhances flexibility, increases ROI, and reduces time-to-market as well as inventories. Therefore, vendors are focusing on using automation and connecting laser cutting machines to a communication network and providing complete integration across the production line using IoT.

Key Laser Cutting Machine Market Challenge in US

The availability of alternate machine tools for metal cutting application will be a major challenge for the laser cutting machine market in US during the forecast period. The availability of waterjet cutting machines has been the major factor affecting the growth of the laser cutting machine market. The use of waterjet cutting machines to cut a wide range of materials and produce high-quality cuts makes them the preferred profiling method in end-user industries. The heat cutting process uses laser or plasma cutting machines for cutting metal parts. However, the excessive heat generated during the cutting process in laser and plasma cutting machines limits their application for materials that are reflective, conductive, heat-resistant, or heat-sensitive. Waterjet cutting is a cold cutting process and applies a mixture of water and an abrasive to cut materials with high precision. It does not create a burr or heat affected zone (HAZ) like the laser and plasma cutting machine, thereby saves expenses for secondary operations such as polishing and restoration. Therefore, the ability of waterjet cutting machines to precisely cut heat-sensitive and heat resistant materials without generating heat has increased their popularity among end-user industries, such as construction, automotive, electronics and electrical, and aerospace. Collectively, these factors have affected the demand for laser cutting machines for heat-sensitive applications.

This laser cutting machine market in US analysis report also provides detailed information on other upcoming trends and challenges that will have a far-reaching effect on the market growth. The actionable insights on the trends and challenges will help companies evaluate and develop growth strategies for 2020-2024.

Parent Market Analysis

Technavio categorizes the global laser cutting machine market in US as a part of the global industrial machinery market. Our research report has extensively covered external factors influencing the parent market growth potential in the coming years, which will determine the levels of growth of the laser cutting machine market in US during the forecast period.

Who are the Major Laser Cutting Machine Market Vendors in US?

The report analyzes the market’s competitive landscape and offers information on several market vendors, including:

- Coherent Inc.

- Conzzeta Management AG

- DMG MORI Co. Ltd.

- IPG Photonics Corp.

- Koike Aronson Inc.

- Laserline GmbH

- Mitsubishi Electric Corp.

- TRUMPF GmbH + Co. KG

- Wuhan HGLaser Engineering Co. Ltd.

This statistical study of the laser cutting machine market in US encompasses successful business strategies deployed by the key vendors. The laser cutting machine market in US is fragmented and the vendors are deploying organic and inorganic growth strategies to compete in the market.

Product Insights and News

-

Coherent Inc. - The company offers RAPID NX Laser, Laser Cutting Systems, META 10C, META 4C, META 2C, Monaco femtosecond laser, StarCut Tube Laser Cutting Machine, and Laser Machines and Systems.

To make the most of the opportunities and recover from post COVID-19 impact, market vendors should focus more on the growth prospects in the fast-growing segments, while maintaining their positions in the slow-growing segments.

The laser cutting machine market in US forecast report offers in-depth insights into key vendor profiles. The profiles include information on the production, sustainability, and prospects of the leading companies.

Laser Cutting Machine Market in US Value Chain Analysis

Our report provides extensive information on the value chain analysis for the laser cutting machine market in US, which vendors can leverage to gain a competitive advantage during the forecast period. The end-to-end understanding of the value chain is essential in profit margin optimization and evaluation of business strategies. The data available in our value chain analysis segment can help vendors drive costs and enhance customer services during the forecast period.

The value chain of the industrial machinery market includes the following core components:

- Inputs

- Inbound logistics

- Operations

- Outbound logistics

- Marketing and sales

- Aftermarket and service

- Industry innovations

The report has further elucidated on other innovative approaches being followed by manufacturers to ensure a sustainable market presence.

What are the Revenue-generating Product Segments in the Laser Cutting Machine Market in US?

To gain further insights on the market contribution of various segments Request for a FREE sample

The laser cutting machine market share growth in US by the fiber segment will be significant during the forecast period. The fiber laser segment is expected to witness stable growth during the forecast period, mainly led by the growing demand from end-user industries, such as automotive, aviation, electrical and electronics, and aerospace and defense. Fiber lasers have helped to bring a new level of flexibility to many industries, allowing for new capabilities, such as the ability to work with many metals that had previously been almost impossible. In addition, other noticeable factors, such as technological advances, being an eco-friendly technology, and growing industrial applications, are expected to contribute to market growth during the forecast period.

This report provides an accurate prediction of the contribution of all the segments to the growth of the laser cutting machine market size in US and actionable market insights on post COVID-19 impact on each segment.

|

Laser Cutting Machine Market Scope in US |

|

|

Report Coverage |

Details |

|

Page number |

120 |

|

Base year |

2019 |

|

Forecast period |

2020-2024 |

|

Growth momentum & CAGR |

Accelerate at a CAGR of 3% |

|

Market growth 2020-2024 |

$ 78.85 million |

|

Market structure |

Fragmented |

|

YoY growth (%) |

2.31 |

|

Regional analysis |

US |

|

Competitive landscape |

Leading companies, Competitive strategies, Consumer engagement scope |

|

Key companies profiled |

Coherent Inc., Conzzeta Management AG, DMG MORI Co. Ltd., IPG Photonics Corp., Koike Aronson Inc., Laserline GmbH, Mitsubishi Electric Corp., TRUMPF GmbH + Co. KG, and Wuhan HGLaser Engineering Co. Ltd. |

|

Market dynamics |

Parent market analysis, Market growth inducers and obstacles, Fast-growing and slow-growing segment analysis, COVID 19 impact and recovery analysis and future consumer dynamics, Market condition analysis for the forecast period |

|

Customization purview |

If our report has not included the data that you are looking for, you can reach out to our analysts and get segments customized. |

What are the Key Data Covered in this Laser Cutting Machine Market in US Report?

- CAGR of the market during the forecast period 2020-2024

- Detailed information on factors that will drive laser cutting machine market growth in US during the next five years

- Precise estimation of the laser cutting machine market size in US and its contribution to the parent market

- Accurate predictions on upcoming trends and changes in consumer behavior

- The growth of the laser cutting machine industry in US

- A thorough analysis of the market’s competitive landscape and detailed information on vendors

- Comprehensive details of factors that will challenge the growth of laser cutting machine market vendors in US

We can help! Our analysts can customize this report to meet your requirements. Get in touch