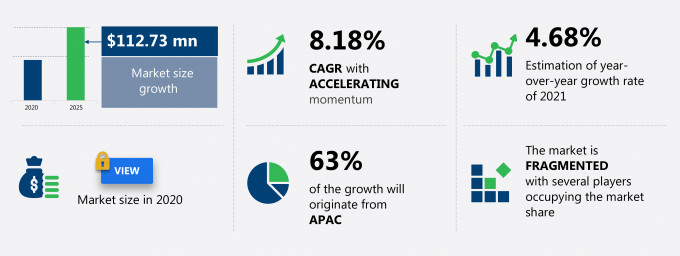

The metal forming and press tending robots market share are expected to increase by USD 112.73 million from 2020 to 2025, and the market’s growth momentum will accelerate at a CAGR of 8.18%.

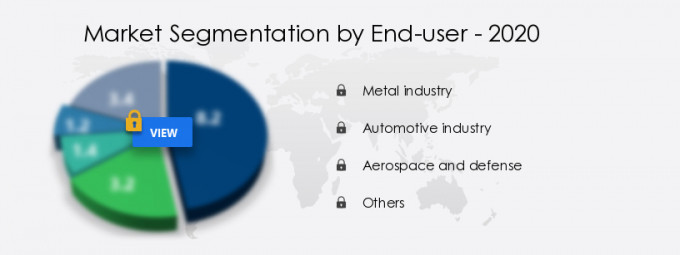

This metal forming and press tending robots market research report provides valuable insights on the post COVID-19 impact on the market, which will help companies evaluate their business approaches. Furthermore, this report extensively covers metal forming and press tending robots market segmentation by end-user (metal industry, automotive industry, aerospace and defense, and others) and geography (APAC, Europe, North America, South America, and MEA). The metal forming and press tending robots market report also offers information on several market vendors, including ABB Ltd., Comau Spa, DENSO Corp., Durr AG, FANUC Corp., Kawasaki Heavy Industries Ltd., KUKA AG, MIDEA GROUP, Mitsubishi Electric Corp., and Yaskawa Electric Corp. among others.

What will the Metal Forming And Press Tending Robots Market Size be During the Forecast Period?

Download Report Sample to Unlock the Metal Forming and Press Tending Robots Market Size for the Forecast Period and Other Important Statistics

Metal Forming And Press Tending Robots Market: Key Drivers, Trends, and Challenges

Based on our research output, there has been a neutral impact on the market growth during and post COVID-19 era. The advantages over automated equipment is notably driving the metal forming and press tending robots market growth, although factors such as the high cost of deployment may impede the market growth. Our research analysts have studied the historical data and deduced the key market drivers and the COVID-19 pandemic impact on the metal forming and press tending robots industry. The holistic analysis of the drivers will help in deducing end goals and refining marketing strategies to gain a competitive edge.

Key Metal Forming And Press Tending Robots Market Driver

Advantages over automated equipment are one of the key factors driving the growth of the global metal forming and press tending robots market. Over the years there has been an increase in the adoption of metal forming and press tending robots due to their ability to work under demanding conditions and give relatively better results than automated equipment used for metal forming and press tending applications. Robots help in achieving high quality and consistency and reduce cost per piece by minimizing the labor input, increasing process efficiency, and decreasing wastage incurred during the process. This eliminates the need to manually feed the metal into the press machines and increases productivity during repetitive tasks. Moreover, vendors have introduced robots that can be easily synchronized with industrial stamping presses and are increasingly being adopted for material handling processes that require parts to be tilted, rotated, and flipped. Also, robots have a better ability than conventional automated equipment to handle metal and alloys that are hard and have high tensile strength, and are challenging to deform by denting perforation, or shearing.

Key Metal Forming And Press Tending Robots Market Trend

Improvement in robotic system integration services will fuel the global metal forming and press tending robots market growth. System integrators are taking initiatives to innovate the delivery of services by capitalizing on technological improvements such as the Internet of Things and software platforms. Vendors are making sure that the necessary development and simulation software for programming robots are up-to-date and include features that make programming hassle-free. Furthermore, software solutions are increasingly being adopted for the improvement in the commissioning and programming of industrial robots, with trends such as virtual commissioning and offline programming expected to gain traction over the forecast period. These include solutions offered by key vendors to improve the efficiency of press tending robots. For instance, Virtual commissioning is a method of gaining traction over onsite commissioning, as it helps in the reduction of time and cost by 50%-60%. Similarly, RoboWave is a complete solution for offline programming to ensure 3D simulation and verification of the feasibility of the cell layout. Such factors will increase the market growth during the forecast period.

Key Metal Forming And Press Tending Robots Market Challenge

The high cost of deployment is the major challenge for the global metal forming and press tending robots market growth. Metal forming and press tending robots involve the use of sensors, software, and advanced technologies, which makes their prices considerably high, thus requiring a large initial one-time payment. This will be a major impediment for potential end-users. Moreover, investments required in the modification of infrastructure and facilities for the adoption of specific robots will add to the costs. The costs also appreciate depending on the customization and other operational requirements based on the intended use of the robots. As the initial cost of procurement of such solutions is high, investment in metal forming and press tending robots is limited to companies that can derive significant cost-benefit from their use. Apart from equipment costs, certain accessories and add-ons, as well as maintenance costs in terms of servicing, electricity, and upgrades, add significantly to the overall expenditure. The high costs associated with the training of specialists and operators for the deployment of robots is also a major challenge for the growth of the market.

This metal forming and press tending robots market analysis report also provides detailed information on other upcoming trends and challenges that will have a far-reaching effect on the market growth. The actionable insights on the trends and challenges will help companies evaluate and develop growth strategies for 2021-2025.

Parent Market Analysis

Technavio categorizes the global metal forming and press tending robots as a part of the global industrial machinery market. Our research report has extensively covered external factors influencing the parent market growth potential in the coming years, which will determine the levels of growth of the metal forming and press tending robots market during the forecast period.

Who are the Major Metal Forming And Press Tending Robots Market Vendors?

The report analyzes the market’s competitive landscape and offers information on several market vendors, including:

- ABB Ltd.

- Comau Spa

- DENSO Corp.

- Durr AG

- FANUC Corp.

- Kawasaki Heavy Industries Ltd.

- KUKA AG

- MIDEA GROUP

- Mitsubishi Electric Corp.

- Yaskawa Electric Corp.

This statistical study of the metal forming and press tending robots market encompasses successful business strategies deployed by the key vendors. The metal forming and press tending robots market is fragmented and the vendors are deploying organic and inorganic growth strategies to compete in the market.

Product Insights and News

- ABB Ltd. - The company offers metal forming and press tending robots under the brand name IRB 140, IRB 1600, and more.

To make the most of the opportunities and recover from post COVID-19 impact, market vendors should focus more on the growth prospects in the fast-growing segments, while maintaining their positions in the slow-growing segments.

The metal forming and press tending robots market forecast report offer in-depth insights into key vendor profiles. The profiles include information on the production, sustainability, and prospects of the leading companies.

Metal Forming And Press Tending Robots Market Value Chain Analysis

Our report provides extensive information on the value chain analysis for the metal forming and press tending robots market, which vendors can leverage to gain a competitive advantage during the forecast period. The end-to-end understanding of the value chain is essential in profit margin optimization and evaluation of business strategies. The data available in our value chain analysis segment can help vendors drive costs and enhance customer services during the forecast period.

The value chain of the global industrial machinery market includes the following core components:

- Inputs

- Inbound logistics

- Operations

- Outbound logistics

- Marketing and sales

- Service

- Support activities

- Innovation

The report has further elucidated other innovative approaches being followed by manufacturers to ensure a sustainable market presence.

Which are the Key Regions for Metal Forming And Press Tending Robots Market?

For more insights on the market share of various regions Request PDF Sample now!

63% of the market’s growth will originate from APAC during the forecast period. China, Japan, and South Korea (Republic of Korea) are the key markets for the metal forming and press tending robots market in APAC. Market growth in this region will be faster than the growth of the market in regions.

Advantages over automated equipment will facilitate the metal forming and press tending robots market growth in APAC over the forecast period. This market research report entails detailed information on the competitive intelligence, marketing gaps, and regional opportunities in store for vendors, which will assist in creating efficient business plans.

COVID Impact and Recovery Analysis

In 2020, the metal forming and press tending robots market in APAC witnessed certain challenges due to the outbreak of COVID-19. Countries such as China, India, South Korea, and Japan were affected by the pandemic in the region. The pandemic also affected the economy of the region, the supply chain, and the industrial, commercial, and service sectors. To prevent the community's spread of the disease, many countries in the region announced another lockdown, which led to the temporary closure of industries such as transportation, construction, hotels, and shopping malls. The temporary closure of various industries due to the implementation of lockdowns led to a decline in the use of robotic technology. This hindered the growth of the market in the region in 2020. However, the increasing automation and safety of individuals, in the long run, is expected to increase the demand for metal forming and press tending robots in the industrial and service sectors, which, in turn, will contribute to the growth of the market during the forecast period.

What are the Revenue-generating End-user Segments in the Metal Forming And Press Tending Robots Market?

To gain further insights on the market contribution of various segments Request a PDF Sample

The metal forming and press tending robots market share growth by the metal industry segment will be significant during the forecast period. This segment includes the revenue generated by the use of metal forming and press tending robots in the production of industrial equipment and machinery that are used in sectors such as food processing, packaging, automotive, aerospace and defense, rubber and plastic, machine tools, construction, agriculture, and forestry

This report provides an accurate prediction of the contribution of all the segments to the growth of the metal forming and press tending robots market size and actionable market insights on post-COVID-19 impact on each segment.

|

Metal Forming And Press Tending Robots Market Scope |

|

|

Report Coverage |

Details |

|

Page number |

120 |

|

Base year |

2020 |

|

Forecast period |

2021-2025 |

|

Growth momentum & CAGR |

Accelerate at a CAGR of 8.18% |

|

Market growth 2021-2025 |

$ 112.73 million |

|

Market structure |

Fragmented |

|

YoY growth (%) |

4.68 |

|

Regional analysis |

APAC, Europe, North America, South America, and MEA |

|

Performing market contribution |

APAC at 63% |

|

Key consumer countries |

China, US, Japan, Germany, and South Korea (Republic of Korea) |

|

Competitive landscape |

Leading companies, Competitive Strategies, Consumer engagement scope |

|

Key companies profiled |

ABB Ltd., Comau Spa, DENSO Corp., Durr AG, FANUC Corp., Kawasaki Heavy Industries Ltd., KUKA AG, MIDEA GROUP, Mitsubishi Electric Corp., and Yaskawa Electric Corp. |

|

Market dynamics |

Parent market analysis, Market growth inducers and obstacles, Fast-growing and slow-growing segment analysis, COVID 19 impact and recovery analysis and future consumer dynamics, Market condition analysis for the forecast period |

|

Customization purview |

If our report has not included the data that you are looking for, you can reach out to our analysts and get segments customized. |

What are the Key Data Covered in this Metal Forming And Press Tending Robots Market Report?

- CAGR of the market during the forecast period 2021-2025

- Detailed information on factors that will drive metal forming and press tending robots market growth during the next five years

- Precise estimation of the metal forming and press tending robots market size and its contribution to the parent market

- Accurate predictions on upcoming trends and changes in consumer behavior

- The growth of the metal forming and press tending robots industry across APAC, Europe, North America, South America, and MEA

- A thorough analysis of the market’s competitive landscape and detailed information on vendors

- Comprehensive details of factors that will challenge the growth of metal forming and press tending robots market vendors

We can help! Our analysts can customize this report to meet your requirements. Get in touch