Metal Forming Machine Tools Market Size 2024-2028

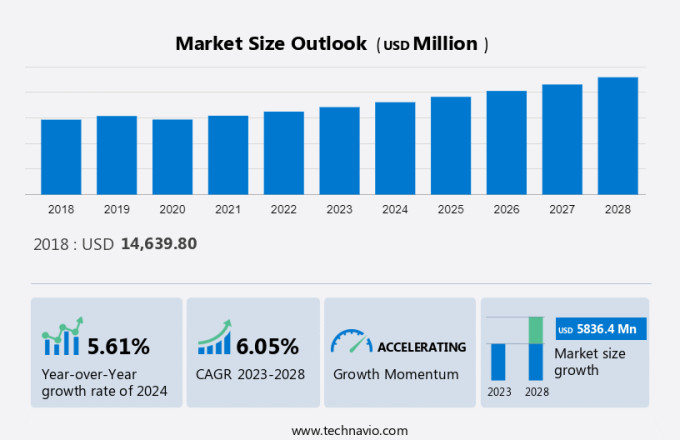

The Metal Forming Machine Tools Market size is forecast to increase by USD 5.84 billion, at a CAGR of 6.05% between 2023 and 2028. The market is experiencing significant growth, driven by the increasing demand for large-scale industrial automation worldwide. Governments' initiatives to promote the machine tools industry, particularly in developing countries, are also fueling market expansion. CNC-incorporated machine tools are becoming essential in this landscape, offering precision and efficiency in metal forming processes. Additionally, the automotive sector is a major driver, with rising automation needs in manufacturing. However, the market is not without challenges. Fluctuating raw material prices pose a significant threat to the profitability of metal forming machine tool manufacturers. Moreover, the market is witnessing intense competition, with numerous players vying for market share. To stay competitive, companies are investing in research and development to introduce innovative products and solutions. The adoption of Industry 4.0 and the integration of advanced technologies such as artificial intelligence, robotics, and the Internet of Things are key trends shaping the market. Overall, the market is expected to continue its growth trajectory, driven by these trends and the increasing demand for automation in various industries.

What will be the Size of the Market During the Forecast Period?

Market Forecast 2024-2028

To learn more about this report, Request Free Sample

Market Dynamics

Key Market Driver - Rising demand for CNC-incorporated machine tools

There has been a significant investment in R&D in the market which is resulting in advances in machine tools, especially CNC machines. The main advantage of CNC machines is that they are highly productive and efficient and facilitate the incorporation of new technologies. There is an increasing adoption of automation in manufacturing operations due to the increasing demand for high-quality products across all industries.

Moreover, there is a growing trend of businesses and investors investing in process automation within the machine tools industry. This includes the increasing adoption of numerical control (NC) and CNC (Computer Numerical Control) machines, replacing manually controlled tools, particularly in small- and medium-scale industries. This shift towards automation is expected to minimize human intervention while significantly enhancing the productivity of bending machines and other machine tools. As industries seek greater efficiency and precision in manufacturing processes, automation plays a crucial role in meeting these demands. These advancements are anticipated to drive substantial market growth in the coming years, aligning with the evolving needs of modern industrial sectors for advanced, automated solutions in bending and other machining operations.

Significant Market Trends - Technological developments in metal forming machine tools

The advancement of technology in the market is resulting in the development of innovative, efficient, easy-to-operate, and time-saving machine tools. There has been a significant revolution in the manufacturing industry with the advent of electrical discharge machines, and ultrasonic, and electronic beam technologies.

Moreover, several companies are launching equipment that showcases improved operational capabilities than conventional machines. Additionally, there are significant innovations in both hardware and software applications that will positively impact the market. Hence, such factors are expected to drive the market during the forecast period.

Major Market Challenge - Fluctuating raw material prices

It has become essential for manufacturers of metal forming machine tools and related accessories to provide specific solutions to fulfill the needs of customers. As a result, there is a significant increase in the capital requirement of these manufacturers. Some of the key raw materials that are used in the manufacturing of these machine tools and their accessories include materials such as steel and iron, aluminum, titanium, copper, brass, and other alloys.

Moreover, these raw materials add to the 8% of the overall production cost of the machine tools whereas labor costs only contribute 27%. Some of the primary raw materials that are used for the preparation of steel include iron ore and steel scrap. However, the demand for steel scrap is highly influenced by the price volatility of iron ore. Hence, factors such as a large share of the cost of raw materials in the total manufacturing cost of machine tools, and the fluctuation in raw material prices disrupt the pricing strategy of machine tool manufacturers and negatively impact the market. Hence, such factors are expected to hinder the market growth during the forecast period.

Market Segmentation

End-User Segment Analysis:

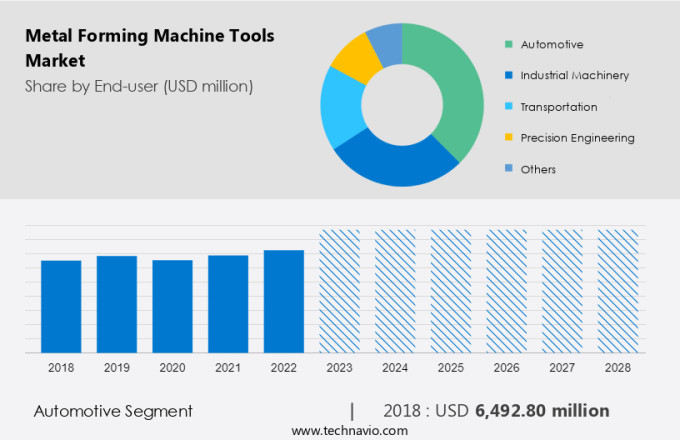

The automotive segment is estimated to witness significant growth during the forecast period. The automotive segment comprises passenger cars, light commercial vehicles, heavy commercial vehicles, and others (including buses and coaches). The key driving factors for the automotive segment are low-interest rates and low fuel prices. Technavio anticipates that Asian countries such as India, Indonesia, and Japan will put forth substantial investments during the forecast period toward acquiring evolving technologies, especially for manufacturing processes.

Get a Customised Report as per your requirements for FREE!

The automotive segment was the largest segment and was valued at USD 6.49 billion in 2018. Moreover, one of the primary characteristics of automotive manufacturing is the high use of various ferrous and non-ferrous metals that are shaped into appropriate designs and then assembled to build the vehicle. The most common applications of metal forming machine tools in the automotive industry are in the manufacture of the following car parts Engine: Pistons, crankshafts, and connecting rods, Body: Chassis and doors, and Suspension system: Rims and shock absorbers. The high volume of automotive production across the world is fueling the demand for metal forming machine tools from automotive OEMs and automotive component manufacturers. For instance, in 2021, 79.1 million motor vehicles were produced globally. Automotive production is expected to steadily increase during the forecast period as the demand for automobiles is anticipated to increase in emerging economies, such as India and Indonesia. This will have a positive influence on the growth of the automotive segment of the global metal forming machine tools market during the forecast period.

Regional Analysis

For more insights on the market share of various regions View PDF Sample now!

APAC is estimated to contribute 63% to the growth by 2028. Technavio's analysts have elaborately explained the regional trends, drivers, and challenges that are expected to shape the market during the forecast period. One of the main factors that is significantly contributing to the growth of the market in APAC is the increasing adoption of machine tools in countries such as China, Japan, India, Taiwan, and South Korea. Additionally, the significant presence of manufacturing facilities in China is fuelling the consumption of machine tools in the country.

Moreover, the rising establishment of manufacturing facilities in the region is expected to increase the demand for machine tools in APAC as well as outpace the demand in developed regions, such as North America and Europe. Furthermore, there is an increase in investment by manufacturers in emerging economies due to low-cost production and the availability of a skilled workforce as well as growing demand for automotive, consumer products, and industrial machinery in the region. Hence, such factors are expected to drive the market growth in APAC during the forecast period.

Who are the Major Market Companies?

Companies are implementing various strategies, such as strategic alliances, partnerships, mergers and acquisitions, geographical expansion, and product/service launches, to enhance their presence in the market.

Accurl CNC Machine Anhui Manufactory Co. Ltd: The company offers metal forming machine tools such as ACCURL press brake smart 3-4 axis series small CNC press brake bending machine.

We also have detailed analyses of the market's competitive landscape and offer information on 20 market companies, including Accurpress Product Sales, AMADA Co. Ltd., Andritz AG, Betenbender Manufacturing Inc., CINCINNATI Inc., DMG MORI Co. Ltd., ECKOLD AG, FAGOR ARRASATE S.COOP., Haas Automation Inc., Hyundai Wia Corp., JIER Machine Tool Group Co. Ltd., Komatsu Ltd., Lodesani and Carreri Srl, Mitsubishi Corp., MONDRAGON Corp., Nidec Corp., Santec Exim Pvt. Ltd., Sumitomo Heavy Industries Ltd., and TRUMPF SE Co. KG

Technavio's market growth and forecasting report provides an in-depth analysis of the market and its players through combined qualitative and quantitative data. The analysis classifies companies into categories based on their business approaches, including pure-play, category-focused, industry-focused, and diversified. Companies are specially categorized into dominant, leading, strong, tentative, and weak, based on their quantitative data analysis.

Segment Overview

The market research and growth report provides comprehensive data (region wise segment analysis), with forecasts and estimates in "USD Billion" for the period 2024 to 2028, as well as historical data from 2018 to 2022 for the following segments.

-

- End-user Outlook

- Automotive

- Industrial machinery

- Transportation

- Precision engineering

- Others

- Type Outlook

- Computerized numerical control

- Conventional

- Geography Outlook

- North America

- The U.S.

- Canada

- Europe

- U.K.

- Germany

- France

- Rest of Europe

- APAC

- China

- India

- South America

- Chile

- Argentina

- Brazil

- Middle East & Africa

- Saudi Arabia

- South Africa

- Rest of the Middle East & Africa

- North America

Market Analyst Overview

The market encompasses a wide range of machinery used for shaping and processing metals. This market includes various types of Forming Machines such as Bending Machines, Shearing Machines, Pressure Machines, Hydraulic Presses, Mechanical Presses, Forging Machines, Wire Forming Machines, Rolling Mill Machines, CNC Bending Machines, and Smart Embedded Systems with IoT Enabled Devices. The Aerospace Industry and Transport Industry are significant consumers of Metal Forming Machine Tools. The Aerospace sector requires high-precision metals and advanced digital technology for manufacturing components, while the Transport Industry relies on conventional technology for mass production. The Metal forming industry also caters to sectors like Electronics, Industrial Manufacturing, Construction, and Transportation.

Automated Equipment, Robotics, Casting Machines, Shearing Devices, Punching Machines, Bulk Forming, and Shear Forming are some of the essential processes in this industry. CNC (Computer Numerical Control) machines and Conventional Machines play a crucial role in the market. While CNC machines offer high accuracy and flexibility, conventional machines cater to industries that require large quantities of standard parts. General Machinery, such as Presses, Rolling Mills, and Shears, are integral to the market. These machines are used for various applications, including bending, stamping, and shearing. The market is expected to grow significantly due to the increasing demand for automation recognition and the adoption of advanced technology in the manufacturing sector.

|

Market Scope |

|

|

Report Coverage |

Details |

|

Page number |

182 |

|

Base year |

2023 |

|

Historic period |

2018-2022 |

|

Forecast period |

2024-2028 |

|

Growth momentum & CAGR |

Accelerate at a CAGR of 6.05% |

|

Market Growth 2024-2028 |

USD 5.84 billion |

|

Market structure |

Fragmented |

|

YoY growth 2023-2024(%) |

5.61 |

|

Regional analysis |

APAC, Europe, North America, South America, and Middle East and Africa |

|

Performing market contribution |

APAC at 63% |

|

Key countries |

China, US, Germany, UK, and Canada |

|

Competitive landscape |

Leading Companies, Market Positioning of Companies, Competitive Strategies, and Industry Risks |

|

Key companies profiled |

Accurl CNC Machine Anhui Manufactory Co. Ltd., Accurpress Product Sales, AMADA Co. Ltd., Andritz AG, Betenbender Manufacturing Inc., CINCINNATI Inc., DMG MORI Co. Ltd., ECKOLD AG, FAGOR ARRASATE S.COOP., Haas Automation Inc., Hyundai Wia Corp., JIER Machine Tool Group Co. Ltd., Komatsu Ltd., Lodesani and Carreri Srl, Mitsubishi Corp., MONDRAGON Corp., Nidec Corp., Santec Exim Pvt. Ltd., Sumitomo Heavy Industries Ltd., and TRUMPF SE Co. KG |

|

Market dynamics |

Parent market growth analysis, Market Forecasting, Market growth inducers and obstacles, Fast-growing and slow-growing segment analysis, COVID-19 impact and recovery analysis and future consumer dynamics, and Market condition analysis for the market forecast period. |

|

Customization purview |

If our market report has not included the data that you are looking for, you can reach out to our analysts and get segments customized. |

What are the Key Data Covered in this Market Research Report?

- CAGR of the market during the forecast period

- Detailed information on factors that will drive the growth of the market between 2024 and 2028

- Precise estimation of the market size and its contribution to the market in focus on the parent market

- Accurate predictions about upcoming trends and changes in consumer behavior

- Growth of the market across APAC, Europe, North America, South America, and the Middle East and Africa

- A thorough analysis of the market's competitive landscape and detailed information about companies

- Comprehensive analysis of factors that will challenge the growth of market companies

We can help! Our analysts can customize this market research report to meet your requirements. Get in touch