Pozzolan Market Size 2024-2028

The pozzolan market size is forecast to increase by USD 15.5 billion at a CAGR of 4.31% between 2023 and 2028.

- The market is experiencing significant growth, driven primarily by the increasing urbanization and infrastructure development in various regions. The upgradation of existing structures and the construction of new ones, particularly in the residential and commercial sectors, have led to a in demand for pozzolan. This naturally occurring mineral enhances the properties of concrete, making it more durable and resilient, which is essential in the face of rising construction costs and a shortage of skilled workforce. However, market growth is not without challenges. Regulations and standards regarding the use of pozzolan in construction projects vary significantly across regions, which can complicate market entry for new players.

- Additionally, the availability and quality of raw materials can impact production costs and profitability. Companies seeking to capitalize on this market opportunity must navigate these challenges effectively, ensuring regulatory compliance, securing reliable supply chains, and maintaining high product quality. By doing so, they can differentiate themselves in a competitive landscape and capture a larger share of the growing the market.

What will be the Size of the Pozzolan Market during the forecast period?

- The market in the US exhibits growth, driven by the increasing demand for supplementary cementitious materials (SCMs) in the construction industry. Pozzolan, an inorganic aluminosilicate binder, enhances the cementing properties of concrete by reacting with calcium hydroxide and water to form a dense, interlocking structure. Industrial waste, such as fly ash and silica fume, are common sources of pozzolan. The production of pozzolan can also be achieved through a chemical method using aqueous alkali hydroxide and alumina, silica, and lime. The resulting material, known as pozzolanic materials, possesses a high specific surface area and reactive SiO2 and Al2O3 content, which contributes to its superior pozzolanic properties.

- Natural pozzolan, such as that found in volcanic ash from Pozzuoli, Italy, used by the Romans, has been replaced by synthetic pozzolan produced from industrial waste. Geopolymer materials, a type of pozzolanic material, have gained popularity due to their nano-structural level properties, offering enhanced strength and durability. Agricultural waste, such as rice husk ash, can also be utilized as a pozzolanic material through natural synthesis. The market is expected to continue its upward trajectory, driven by the growing demand for sustainable and cost-effective construction materials.

How is this Pozzolan Industry segmented?

The pozzolan industry research report provides comprehensive data (region-wise segment analysis), with forecasts and estimates in "USD billion" for the period 2024-2028, as well as historical data from 2018-2022 for the following segments.

- Material

- Artificial pozzolan

- Natural pozzolan

- End-user

- Residential

- Commercial

- Roads and highways

- Others

- Geography

- North America

- US

- APAC

- China

- India

- Europe

- Germany

- UK

- South America

- Middle East and Africa

- North America

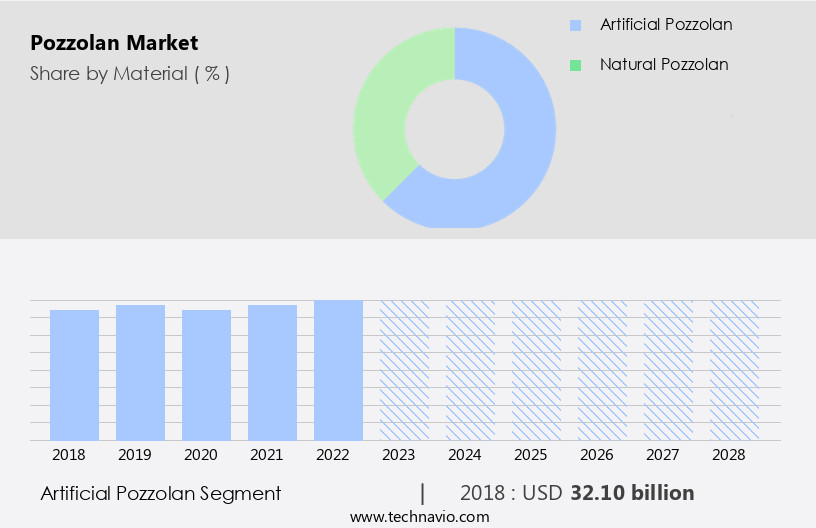

By Material Insights

The artificial pozzolan segment is estimated to witness significant growth during the forecast period.

Artificial pozzolan, derived from industrial processes such as coal burning, contrasts with natural pozzolans. Industrial by-products or heat-treated materials comprise artificial pozzolanic materials, which undergo physical and chemical transformations. Silica fume, a by-product of ferrosilicon alloy and silicon metal production, is an example. During this process, quartz is heated above 2000 degrees Celsius, causing it to transform into silicon. Simultaneously, silicon dioxide vapor forms and later oxidizes and condenses to create silica fume. Other forms of artificial pozzolan include fly ash, blast furnace slag, and glass powder. These materials' altered mineralogical composition and fineness contribute to their pozzolanic reactivity, enhancing the mechanical properties of concretes and mortars.

Their low ecological footprint and carbonation resistance make them desirable in the construction industry. The use of these materials in the cement industry, particularly as supplementary cementitious materials, is a growing trend due to their durability and durability properties. The pozzolanic behaviour of these materials is attributed to their microporous structure, glassy phase, and alkaline solution reaction with calcium hydroxide in cement paste. The setting times and cementing properties of these materials are influenced by factors such as activator concentration, temperature, and the presence of lime. The geopolymer chain formation, a critical aspect of their cementitious properties, is driven by the presence of reactive SiO2 and alkali activated materials.

The use of industrial waste, such as rice husk ash, volcanic ash, metakaolin, and sugarcane bagasse ash, as pozzolanic materials is a sustainable approach to reducing waste and improving the environmental performance of the construction industry. The ongoing research in the field of inorganic aluminosilicate binders and their chemical composition continues to expand the potential applications and benefits of these materials.

Get a glance at the market report of share of various segments Request Free Sample

The Artificial pozzolan segment was valued at USD 32.10 billion in 2018 and showed a gradual increase during the forecast period.

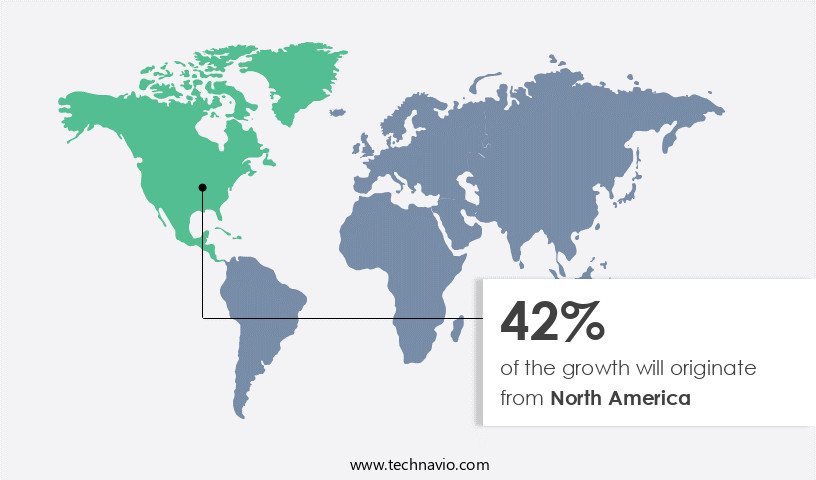

Regional Analysis

North America is estimated to contribute 42% to the growth of the global market during the forecast period.Technavio’s analysts have elaborately explained the regional trends and drivers that shape the market during the forecast period.

For more insights on the market size of various regions, Request Free Sample

The market in North America is experiencing significant growth, with the US being the largest consumer due to increased construction expenditure. In August 2020, construction spending in the US surpassed USD1,412.82 billion, and over 20 residential and transportation terminal projects are anticipated to be developed during the forecast period. The construction industry's expansion in the US, Canada, and Mexico, along with improved public transportation and growing production facilities in Mexico, are driving the demand for pozzolan. Pozzolan, a siliceous or siliceous and aluminous material, enhances the properties of concrete by reducing its permeability, improving its workability, and increasing its carbonation resistance.

The material's microporous structure and durability properties make it an ideal supplementary cementitious material. The pozzolanic reactivity of materials like rice husk ash, volcanic ash, metakaolin, and fly ash is essential in the production of pozzolan. The chemical method, which involves the use of an alkaline solution to activate the pozzolanic reactivity, is commonly used to produce pozzolan. The resulting geopolymer material's physical properties, such as cementing properties, setting times, and mechanical properties, are crucial for its application in various industries. The market's growth is also influenced by the environmental benefits of using pozzolan. Its low ecological footprint and the availability of industrial waste materials like volcanic ashes, tuffs, brick powder, and silica fume as pozzolan sources make it an eco-friendly alternative to traditional cementitious materials.

The mineralogical composition of pozzolan, including its aluminosilicate content, silica, and alumina, significantly impacts its pozzolanic behavior and durability properties. The specific surface area of pozzolan also plays a role in its reactivity and strength development. The Portland cement industry's shift towards the use of pozzolan as a supplementary cementitious material is a significant trend in the market. The use of pozzolan in geopolymer materials, such as concrete and mortar, has gained popularity due to their improved mechanical properties and strength development. In , the market in North America is experiencing growth due to the expanding construction industry and the environmental benefits of using pozzolan.

The availability of industrial waste materials and advancements in the production process are also contributing to the market's growth. The material's pozzolanic properties, including its low ecological footprint, durability, and improved mechanical properties, make it an attractive alternative to traditional cementitious materials.

Market Dynamics

Our researchers analyzed the data with 2023 as the base year, along with the key drivers, trends, and challenges. A holistic analysis of drivers will help companies refine their marketing strategies to gain a competitive advantage.

What are the key market drivers leading to the rise in the adoption of Pozzolan Industry?

- Increasing urbanization is the key driver of the market.

- The population migration trend from rural to urban areas is significant in various countries, particularly in regions such as the Middle East and Africa. According to The World Bank Group, the population growth rates of Sudan and Nigeria in 2021 were 4.64% and 3.66%, respectively. This movement is leading to an increase in urbanization, as reported by statisticsTimes.Com, which indicates that the percentage of urban dwellers reached 56.2% globally in 2020. Although developed countries have a higher urban population rate (79.2% in 2020), the growth rate in developing regions has been noteworthy in recent times.

- Urbanization presents various opportunities and challenges for countries, including economic growth, infrastructure development, and social issues. this trend and its implications is crucial for businesses and policymakers alike.

What are the market trends shaping the Pozzolan Industry?

- Upgradations in usage of pozzolan is the upcoming market trend.

- Pozzolan is a mineral additive that enhances the durability and strength of cement in structures, particularly in moist environments. Due to its resistance to sulfate, water, and other chemical assaults, pozzolan cement is a preferred choice for dams, marine structures, and constructions in areas prone to sulfate attack. Its superior properties become more evident during the later stages of hydration, where the hardness of pozzolan surpasses that of ordinary cement. This makes it an ideal solution for constructing large foundations, high walls, dams, and other massive structures.

- The use of pozzolan cement is crucial in seashore constructions, where the risk of sulfate attack is high, and ordinary cement is not a viable option. The superior hardness and durability of pozzolan cement contribute to its widespread adoption in the construction industry.

What challenges does the Pozzolan Industry face during its growth?

- Increase in construction costs and lack of skilled workforce is a key challenge affecting the industry growth.

- The construction industry relies on various materials, including pozzolan, for building projects. However, the high cost of pozzolan poses a challenge to the market. The pricing dynamics of construction materials create a cycle where the increase in the cost of one material raises the overall construction expenses. This issue is particularly prevalent in countries with volatile economic conditions, such as those in Africa, including Nigeria and Namibia.

- The availability of raw materials for pozzolan production is subject to market demand fluctuations, leading to price instability. As a , it's crucial to acknowledge the challenges that impact the market, including the cost and availability of raw materials. These factors create uncertainty for construction projects, necessitating careful planning and budgeting.

Exclusive Customer Landscape

The pozzolan market forecasting report includes the adoption lifecycle of the market, covering from the innovator’s stage to the laggard’s stage. It focuses on adoption rates in different regions based on penetration. Furthermore, the pozzolan market report also includes key purchase criteria and drivers of price sensitivity to help companies evaluate and develop their market growth analysis strategies.

Customer Landscape

Key Companies & Market Insights

Companies are implementing various strategies, such as strategic alliances, pozzolan market forecast, partnerships, mergers and acquisitions, geographical expansion, and product/service launches, to enhance their presence in the industry.

3M Co. - BASF's innovative pozzolan solution minimizes carbon emissions, lowers cement costs, conserves natural resources, and lessens environmental impact. This offering, marketed under the BASF brand, contributes to sustainable construction projects worldwide.

The industry research and growth report includes detailed analyses of the competitive landscape of the market and information about key companies, including:

- 3M Co.

- BASF SE

- Burgess Pigment Co.

- CARBO Ceramics Inc.

- CEMEX SAB de CV

- Charah Solutions Inc.

- CR Minerals Co. LLC

- HERACLES Group

- Hess Pumice Inc.

- iMinerals Inc.

- Imerys S.A.

- Nebraska Ash

- Nevada Cement Company

- REDÂ Industrial Products

- Salt River Materials Group

- The SEFA Group LLC

- Titan America LLC

Qualitative and quantitative analysis of companies has been conducted to help clients understand the wider business environment as well as the strengths and weaknesses of key industry players. Data is qualitatively analyzed to categorize companies as pure play, category-focused, industry-focused, and diversified; it is quantitatively analyzed to categorize companies as dominant, leading, strong, tentative, and weak.

Research Analyst Overview

The market encompasses a diverse range of inorganic materials that exhibit pozzolanic properties, contributing significantly to the production of high-performance and sustainable construction materials. These materials, which include argillaceous and volcanic origin, undergo a chemical reaction when combined with an alkaline solution, leading to the formation of calcium silicate hydrates. The fineness of pozzolans plays a crucial role in their reactivity. A smaller particle size facilitates a larger surface area, increasing the potential for contact with the activator, thereby enhancing the pozzolanic reactivity. The alkaline solution, often derived from lime or an aqueous alkali hydroxide, initiates the pozzolanic reaction, which results in the development of concrete's desirable mechanical properties.

The glassy phase, a characteristic feature of some pozzolans, contributes to the carbonation resistance and durability of concretes. The microporous structure of these materials allows for efficient water absorption and retention, which is essential for maintaining the workability and setting times of the cement paste. The market is driven by the demand for materials with a low ecological footprint. Natural pozzolans, such as rice husk ash, volcanic ash, metakaolin, and tuffs, offer an eco-friendly alternative to traditional Portland cement. These materials undergo a chemical method of activation, which reduces the need for high temperatures and large amounts of energy compared to the production of Portland cement.

The mineralogical composition of pozzolans plays a significant role in their pozzolanic properties. The presence of reactive silica and alumina, along with alkaline metal cations, contributes to the formation of calcium silicate hydrates. The strength activity index of pozzolans is influenced by their chemical composition, with a higher index indicating a more reactive material. The market is witnessing growing interest in the use of industrial waste, such as fly ash and pyroclastic ashes, as supplementary cementitious materials. These materials offer several advantages, including reduced carbon emissions, improved workability, and enhanced durability properties. The physical properties of pozzolanic materials, including their permeability, compact layers, and cementing properties, make them suitable for various applications, such as building blocks, mortar, and lightweight aggregate.

The mechanical properties of geopolymer materials, which are derived from pozzolanic reactivity, are comparable to those of Portland cement concretes, making them an attractive alternative in the construction industry. The market is influenced by several factors, including the availability of raw materials, technological advancements, and regulatory requirements. The market is expected to grow as the construction industry shifts towards more sustainable and high-performance materials. The use of pozzolans in the production of concretes and other construction materials offers several benefits, including improved durability, enhanced workability, and reduced ecological footprint. The ongoing research in the field of pozzolanic materials is expected to lead to new applications and innovations, further expanding the scope of the market.

|

Market Scope |

|

|

Report Coverage |

Details |

|

Page number |

151 |

|

Base year |

2023 |

|

Historic period |

2018-2022 |

|

Forecast period |

2024-2028 |

|

Growth momentum & CAGR |

Accelerate at a CAGR of 4.31% |

|

Market growth 2024-2028 |

USD 15.5 billion |

|

Market structure |

Fragmented |

|

YoY growth 2023-2024(%) |

4.09 |

|

Key countries |

US, China, India, UK, and Germany |

|

Competitive landscape |

Leading Companies, Market Positioning of Companies, Competitive Strategies, and Industry Risks |

What are the Key Data Covered in this Pozzolan Market Research and Growth Report?

- CAGR of the Pozzolan industry during the forecast period

- Detailed information on factors that will drive the growth and forecasting between 2024 and 2028

- Precise estimation of the size of the market and its contribution of the industry in focus to the parent market

- Accurate predictions about upcoming growth and trends and changes in consumer behaviour

- Growth of the market across North America, APAC, Europe, South America, and Middle East and Africa

- Thorough analysis of the market’s competitive landscape and detailed information about companies

- Comprehensive analysis of factors that will challenge the pozzolan market growth of industry companies

We can help! Our analysts can customize this pozzolan market research report to meet your requirements.