Scraped Surface Heat Exchanger Market Size 2024-2028

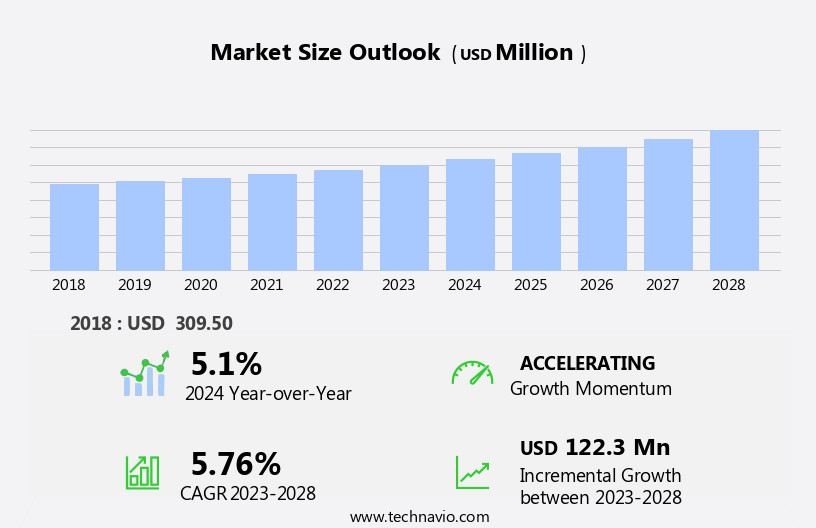

The scraped surface heat exchanger (SSHE) market size is forecast to increase by USD 122.3 million at a CAGR of 5.76% between 2023 and 2028.

- The market is experiencing significant growth due to the operational benefits they offer over traditional heat exchanger designs. SSHEs provide enhanced heat transfer efficiency, reduced fouling, and easier cleaning, making them an attractive option for industries such as food and beverage, pharmaceuticals, and chemicals. Technological advances in SSHE design continue to drive innovation, with improvements in materials, geometry, and manufacturing processes leading to increased performance and cost savings. The market's competitive landscape is shaped by the presence of numerous manufacturers, particularly in the Asia Pacific region, who offer low-cost production and cater to the growing demand for SSHEs. However, challenges remain, including the high initial investment cost and the need for specialized maintenance and operation expertise.

- Companies seeking to capitalize on this market's opportunities must focus on optimizing their designs, expanding their production capabilities, and providing comprehensive support services to customers. By staying abreast of technological advancements and market trends, they can effectively navigate challenges and maintain a competitive edge.

What will be the Size of the Scraped Surface Heat Exchanger (Sshe) Market during the forecast period?

- The market is experiencing significant growth driven by the increasing demand for energy efficiency and process optimization in various industries. Key market dynamics include the optimization of shear rate for enhanced heat transfer, the expansion of heat transfer area to improve thermal capacity, and the reduction of fouling resistance for longer operational life. Spare parts and life cycle assessment play crucial roles in minimizing downtime and maximizing cost savings. Pressure drop, heat transfer modeling, and process safety are essential considerations for effective design and operation. Advanced technologies such as control valves, pressure sensors, residence time measurement, flow meters, temperature sensors, and data logging facilitate optimal process control and monitoring.

- Additionally, the integration of product lifecycle management, level sensors, computational fluid dynamics, thermal analysis, and data acquisition systems enhances overall system performance and efficiency. Environmental impact and carbon footprint reduction are also key priorities for businesses in the market. Explosion protection and technical support are vital for ensuring process safety and minimizing downtime.

How is this Scraped Surface Heat Exchanger Industry segmented?

The scraped surface heat exchanger (sshe) industry research report provides comprehensive data (region-wise segment analysis), with forecasts and estimates in "USD million" for the period 2024-2028, as well as historical data from 2018-2022 for the following segments.

- End-user

- Processed food

- Bakery

- Dairy

- Fats and oils

- Others

- Product

- Reciprocating tubular

- Rotating tubular

- Rotating plate

- Application

- Food Processing

- Chemical Processing

- Pharmaceutical

- Geography

- North America

- US

- Canada

- Europe

- France

- Germany

- Italy

- UK

- Middle East and Africa

- Egypt

- KSA

- Oman

- UAE

- APAC

- China

- India

- Japan

- South America

- Argentina

- Brazil

- Rest of World (ROW)

- North America

By End-user Insights

The processed food segment is estimated to witness significant growth during the forecast period.

Processed food manufacturing relies significantly on advanced technologies to ensure product quality and efficiency. Scraped surface heat exchangers, for instance, are integral components in this sector, facilitating heating, cooling, crystallization, pasteurization, and evaporation processes for various food products. These exchangers employ high viscosity fluids, such as thermal oil, for heat transfer, enhancing energy efficiency and thermal efficiency. Process intensification is another critical trend in the industry, with performance monitoring and design optimization playing essential roles. Stainless steel, known for its corrosion resistance and hygienic design, is commonly used in food processing equipment. Advanced materials, including nickel alloys, are selected based on their heat transfer rate and thermal efficiency for optimal process heating.

Data analytics and temperature control are crucial for maintaining product consistency and ensuring food safety. Digital transformation and process control systems enable real-time monitoring and analysis of production processes, while plate heat exchangers facilitate efficient heat transfer between two fluids. Heat transfer fluids, including those with enhanced properties, are employed to optimize energy savings. Food processing also focuses on wastewater treatment and energy efficiency, with cost reduction being a significant factor. The integration of the Internet of Things (IoT) in food processing systems allows for automated process optimization and real-time process monitoring, ensuring high-quality output and reducing operational costs.

Get a glance at the market report of share of various segments Request Free Sample

The Processed food segment was valued at USD 66.10 million in 2018 and showed a gradual increase during the forecast period.

Regional Analysis

Europe is estimated to contribute 34% to the growth of the global market during the forecast period.Technavio's analysts have elaborately explained the regional trends and drivers that shape the market during the forecast period.

For more insights on the market size of various regions, Request Free Sample

The European market holds a significant position in the global scraped surface heat exchanger (SSHE) industry, leading in both production and demand. Key players in this sector are primarily based in Europe, with the UK, Germany, and France being major contributors. The region's dominance can be attributed to the replacement of outdated SSHEs with more efficient models, driven by the food and beverage and automotive industries. Germany, a global leader in food production, particularly in the healthy, high-quality, and safe food sector, significantly influences the market's growth. Advanced technologies such as process intensification, performance monitoring, and digital transformation are increasingly adopted to enhance heat transfer efficiency and product quality.

Stainless steel, thermal oil, and heat transfer fluids are commonly used materials in SSHEs for their corrosion resistance and energy savings. Additionally, process optimization, material selection, and heat transfer rate are crucial factors in the market's evolution. Nickel alloys and plate heat exchangers are also gaining popularity due to their thermal efficiency and heat transfer enhancement capabilities. The integration of data analytics, temperature control, and process control further improves the overall performance of SSHEs. The market's future trends include energy savings through the Internet of Things and the use of advanced materials for improved heat transfer and process heating.

Cost reduction remains a significant driver, with companies focusing on process optimization and wastewater treatment to minimize expenses.

Market Dynamics

Our researchers analyzed the data with 2023 as the base year, along with the key drivers, trends, and challenges. A holistic analysis of drivers will help companies refine their marketing strategies to gain a competitive advantage.

What are the key market drivers leading to the rise in the adoption of Scraped Surface Heat Exchanger Industry?

- Operational benefits associated with scraped surface heat exchangers is the key driver of the market. Scraped surface heat exchangers (SSHEs) offer notable operational advantages over conventional heat exchangers. These advanced heat exchangers facilitate increased heat transfer by forcefully mixing fluids, leading to a higher volume of fluid in direct contact with the equipment. This results in enhanced heat transfer rates and a reduced surface area requirement. SSHEs are particularly beneficial in handling thick, sticky, viscous materials containing particulate matter or requiring crystallization, where fouling reduces heat transfer or viscous fluids exhibit low heat transfer rates.

- SSHEs' ability to efficiently transfer heat in such applications makes them an essential choice for various industries.

What are the market trends shaping the Scraped Surface Heat Exchanger Industry?

- Technological advances in design of heat exchangers is the upcoming market trend. Heat exchangers play a crucial role in optimizing energy efficiency by facilitating heat transfer between two fluids with minimal energy loss. One such advanced type is the Scraped Surface Heat Exchanger (SHE), which delivers enhanced heat transfer coefficients, up to three to five times greater than traditional shell and tube heat exchangers. Alfa Laval's Alfa Laval Compabloc is an example of this technology, which achieves high turbulence and minimizes fouling, enabling the use of corrosion-resistant exotic metals. Several market participants have recognized the potential of geothermal resources and are actively exploring their application in the field of geothermal energy conversion.

- Medium- to low-temperature geothermal resources have gained significant attention in recent research due to their potential financial viability. The market dynamics reflect a growing focus on sustainable energy solutions and the increasing demand for efficient heat transfer systems.

What challenges does the Scraped Surface Heat Exchanger Industry face during its growth?

- Presence of manufacturers in APAC that offer low-cost products is a key challenge affecting the industry growth. The Asia Pacific (APAC) region's low cost of labor, land, and raw materials makes it an attractive investment destination for the manufacturing sector. Several industries in APAC prioritize energy-efficient machinery and solutions, leading to increased demand for scraped surface heat exchangers. companies supplying these exchangers seek partnerships with affordable subcomponent suppliers to cater to cost-conscious end-users. APAC companies, including those from China and Japan, have expanded their reach to the Americas and Europe due to their competitive pricing. This trend is driven by the abundance of resources in APAC, enabling the production of low-cost scraped surface heat exchangers.

Exclusive Customer Landscape

The scraped surface heat exchanger (sshe) market forecasting report includes the adoption lifecycle of the market, covering from the innovator's stage to the laggard's stage. It focuses on adoption rates in different regions based on penetration. Furthermore, the scraped surface heat exchanger (sshe) market report also includes key purchase criteria and drivers of price sensitivity to help companies evaluate and develop their market growth analysis strategies.

Customer Landscape

Key Companies & Market Insights

Companies are implementing various strategies, such as strategic alliances, scraped surface heat exchanger (sshe) market forecast, partnerships, mergers and acquisitions, geographical expansion, and product/service launches, to enhance their presence in the industry.

The industry research and growth report includes detailed analyses of the competitive landscape of the market and information about key companies, including:

- Alfa Laval AB

- Armstrong Engineering Associates

- Armfield Ltd.

- Aurum Process Technology SL

- AxFlow

- Buhler AG

- EMA Europe S.R.O.

- Exchanger Industries Ltd.

- Gemak

- Gerstenberg Services AS

- GPE Process Equipment

- Gpi De Gouwe

- Holland Applied Technologies

- JH Stalindustri AS

- KNM Group Berhad

- LaGrange Products Inc.

- Proxes GmbH

- RONO Maschinenbau GmbH

- SPX FLOW Inc.

- Tantec AS

Qualitative and quantitative analysis of companies has been conducted to help clients understand the wider business environment as well as the strengths and weaknesses of key industry players. Data is qualitatively analyzed to categorize companies as pure play, category-focused, industry-focused, and diversified; it is quantitatively analyzed to categorize companies as dominant, leading, strong, tentative, and weak.

Research Analyst Overview

Scraped surface heat exchangers (SSHEs) have gained significant attention in various industries due to their ability to handle high viscosity fluids and ensure efficient process intensification. These heat exchangers employ a rotating scraper mechanism to maintain a consistent film of fluid against the heat transfer surface, enhancing heat transfer rates and thermal efficiency. The market for SSHEs is driven by the increasing demand for energy efficiency and cost reduction in industrial processes. The use of SSHEs in thermal oil applications, wastewater treatment, and food processing industries is particularly noteworthy, as these sectors require effective temperature control and hygienic design.

Performance monitoring and design optimization are crucial aspects of SSHE operation. Advanced materials, such as stainless steel and nickel alloys, are often utilized to ensure corrosion resistance and prolong the life cycle of these exchangers. Additionally, data analytics and process control systems enable continuous optimization of energy savings and product quality. Heat transfer enhancement is a significant focus in the SSHE market, with the integration of digital transformation and the Internet of Things (IoT) enabling real-time process monitoring and optimization. Plate heat exchangers, a common alternative to SSHEs, are increasingly being replaced due to the advantages offered by SSHEs in terms of energy savings and process optimization.

Process heating applications are another key area where SSHEs are gaining popularity due to their ability to handle high viscosity fluids and maintain consistent temperatures. The market for SSHEs is expected to grow as industries continue to seek more efficient and cost-effective solutions for their process heating needs. The use of SSHEs in various industries is not limited to traditional applications. For instance, in the food processing sector, SSHEs are employed to ensure product quality and hygiene while minimizing energy consumption. In the wastewater treatment industry, SSHEs are used to maintain optimal temperatures for efficient biological processes, leading to enhanced treatment performance.

In conclusion, the market for SSHEs is driven by the need for energy efficiency, cost reduction, and process optimization across various industries. The ability of SSHEs to handle high viscosity fluids and maintain consistent temperatures makes them an attractive alternative to traditional heat exchangers. The integration of advanced materials, digital transformation, and process control systems further enhances the performance and versatility of SSHEs.

|

Market Scope |

|

|

Report Coverage |

Details |

|

Page number |

173 |

|

Base year |

2023 |

|

Historic period |

2018-2022 |

|

Forecast period |

2024-2028 |

|

Growth momentum & CAGR |

Accelerate at a CAGR of 5.76% |

|

Market growth 2024-2028 |

USD 122.3 million |

|

Market structure |

Fragmented |

|

YoY growth 2023-2024(%) |

5.1 |

|

Key countries |

US, Canada, Germany, UK, Italy, France, China, India, Japan, Brazil, Egypt, UAE, Oman, Argentina, KSA, UAE, Brazil, and Rest of World (ROW) |

|

Competitive landscape |

Leading Companies, Market Positioning of Companies, Competitive Strategies, and Industry Risks |

What are the Key Data Covered in this Scraped Surface Heat Exchanger Market Research and Growth Report?

- CAGR of the Scraped Surface Heat Exchanger industry during the forecast period

- Detailed information on factors that will drive the growth and forecasting between 2024 and 2028

- Precise estimation of the size of the market and its contribution of the industry in focus to the parent market

- Accurate predictions about upcoming growth and trends and changes in consumer behaviour

- Growth of the market across Europe, APAC, North America, South America, and Middle East and Africa

- Thorough analysis of the market's competitive landscape and detailed information about companies

- Comprehensive analysis of factors that will challenge the scraped surface heat exchanger market growth of industry companies

We can help! Our analysts can customize this scraped surface heat exchanger market research report to meet your requirements.