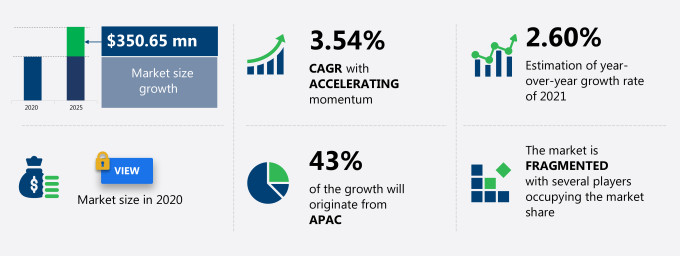

The vinyl ester market share is expected to increase by USD 350.65 million from 2020 to 2025, and the market’s growth momentum will accelerate at a CAGR of 3.54%.

This vinyl ester market research report provides valuable insights on the post COVID-19 impact on the market, which will help companies evaluate their business approaches. Furthermore, this report extensively covers vinyl ester market segmentation by application (pipes and tanks, marine, FGD, wind energy, and others) and geography (APAC, North America, Europe, South America, and MEA). The vinyl ester market report also offers information on several market vendors, including Allnex Netherlands BV, AOC LLC, Ashland Global Holdings Inc., DIC Corp., Hexion Inc., Interplastic Corp., Orca Composites, Reichhold LLC, SHOWA DENKO K.K., and Swancor Holding Co. Ltd. among others.

What will the Vinyl Ester Market Size be During the Forecast Period?

Download Report Sample to Unlock the Vinyl Ester Market Size for the Forecast Period and Other Important Statistics

Vinyl Ester Market: Key Drivers, Trends, and Challenges

The increased demand for corrosion-resistant pipes and storage tanks is notably driving the vinyl ester market growth, although factors such as the threat of substitutes may impede the market growth. Our research analysts have studied the historical data and deduced the key market drivers and the COVID-19 pandemic impact on the vinyl ester industry. The holistic analysis of the drivers will help in deducing end goals and refining marketing strategies to gain a competitive edge.

Key Vinyl Ester Market Driver

Increased demand for corrosion-resistant pipes and storage tanks is one of the major drivers of the market in focus. Corrosion resistance is one of the key selling points of vinyl ester resins over conventional materials that are used for the manufacturing of pipes and storage tanks. Vinyl ester resins offer superior chemical resistance, low permeability, abrasion resistance, and flexibility, because of which they are used as matrix materials to fabricate FRP for manufacturing storage tanks and pipes. Vinyl ester resins are prevalent in materials for steel and concrete tank linings, pipe linings, and secondary containment. They are combined with special curing systems to be used as high chemical abrasion-resistant thick films for tank lining services. They are used in pipes and ducting, tanks and storage vessels, and pipelining systems. The increase in demand for underground storage tanks, tanks for corrosive chemicals, pressure-transfer pipes, and effluent management requires special corrosion resin formulations. The FRP pipes and tank installations made of vinyl ester resins are more preferred to conventional materials due to their low cost and corrosion resistance to chemicals, alkalis, and other corrosive materials.

Key Vinyl Ester Market Trend

Increased use of vinyl ester in FRP is one of the key trends for the market in focus. FRP is used in numerous applications that include pulp and paper, power, waste treatment, semiconductor, metals refining, petrochemical, pharmaceutical, and others. FRP made of vinyl ester resins has been replacing conventional materials such as steel, wood, aluminum, and concrete. The flexible nature of vinyl ester produces parts that can withstand high impact and repeated flexing without developing cracks. In addition, FRP composites based on epoxy vinyl ester resins are used in the aerospace and transportation industries due to their lightweight, durability, low density, fire retardancy, corrosion resistance, and high strength. The increased use of FRP in different end-user industries will impact the demand for vinyl ester positively over the forecast period.

Key Vinyl Ester Market Challenge

The threat of substitutes will be a major challenge for the vinyl ester market growth. The presence of substitutes such as polyester resins, polyurethanes, epoxy, phenolic, and other resins poses a challenge to the growth of the global vinyl ester market as these substitutes exhibit similar characteristics as vinyl ester resins. Apart from this, the market faces a challenge from thermoplastic resins, including polypropylene, polyethylene, and polyvinyl chloride. The development of new solutions by thermoplastic and biodegradable resin manufacturers also poses a threat to the global vinyl ester market. The growing need for technological advances to acquire increased durability, stiffness, fuel efficiency, and cost reduction from secondary operations prefer advanced structural materials in the end-use industries. Therefore, the competition from advanced materials, thermoplastic resins, and other thermoset resins for manufacturing end-user industrial products will hamper the growth of the global vinyl ester market.

This vinyl ester market analysis report also provides detailed information on other upcoming trends and challenges that will have a far-reaching effect on the market growth. The actionable insights on the trends and challenges will help companies evaluate and develop growth strategies for 2021-2025.

Parent Market Analysis

Technavio categorizes the global vinyl ester market as a part of the global diversified chemicals market. Our research report has extensively covered external factors influencing the parent market growth potential in the coming years, which will determine the levels of growth of the vinyl ester market during the forecast period.

Who are the Major Vinyl Ester Market Vendors?

The report analyzes the market’s competitive landscape and offers information on several market vendors, including:

- Allnex Netherlands BV

- AOC LLC

- Ashland Global Holdings Inc.

- DIC Corp.

- Hexion Inc.

- Interplastic Corp.

- Orca Composites

- Reichhold LLC

- SHOWA DENKO K.K.

- Swancor Holding Co. Ltd.

This statistical study of the vinyl ester market encompasses successful business strategies deployed by the key vendors. The vinyl ester market is fragmented and the vendors are deploying growth strategies such as developing innovative products and are constantly increasing their R&D investments to compete in the market.

To make the most of the opportunities and recover from post COVID-19 impact, market vendors should focus more on the growth prospects in the fast-growing segments, while maintaining their positions in the slow-growing segments.

The vinyl ester market forecast report offers in-depth insights into key vendor profiles. The profiles include information on the production, sustainability, and prospects of the leading companies.

Vinyl Ester Market Value Chain Analysis

Our report provides extensive information on the value chain analysis for the vinyl ester market, which vendors can leverage to gain a competitive advantage during the forecast period. The end-to-end understanding of the value chain is essential in profit margin optimization and evaluation of business strategies. The data available in our value chain analysis segment can help vendors drive costs and enhance customer services during the forecast period.

The value chain of the diversified chemicals market includes the following core components:

- Inputs

- Inbound logistics

- Operations

- Outbound logistics

- Marketing and sales

- Service

- Support activities

- Innovation

The report has further elucidated other innovative approaches being followed by manufacturers to ensure a sustainable market presence.

Which are the Key Regions for Vinyl Ester Market?

For more insights on the market share of various regions Request PDF Sample now!

43% of the market's growth will originate from APAC during the forecast period. China and Japan are the key markets for vinyl ester in APAC. Market growth in APAC will be faster than the growth of the market in other regions.

The growth of the oil and gas, transportation, wind energy, and building and construction industries will facilitate the vinyl ester market growth in APAC over the forecast period. This market research report entails detailed information on the competitive intelligence, marketing gaps, and regional opportunities in store for vendors, which will assist in creating efficient business plans.

COVID Impact and Recovery Analysis

The outbreak of the COVID-19 pandemic led to a decline in the sale of vinyl ester in APAC in 2020. In addition, manufacturing units were temporarily closed in the region. Countries such as India, China, Japan, South Korea were among those severely affected by the pandemic in 2020. Therefore, the countries in the region focused on containing the COVID-19 pandemic, which led to the closure of various manufacturing units such as automotive and others in 2020. However, with the marked decline in the number of COVID-19 cases following the rising vaccination coverage in the first half of 2021, players in the chemical industry have resumed production activities in the region, which, in turn, has fueled market growth. Thus, the rapid growth in industrialization in emerging economies such as India and China will boost the demand for vinyl ester in the region during the forecast period.

What are the Revenue-generating Application Segments in the Vinyl Ester Market?

To gain further insights on the market contribution of various segments Request PDF Sample

The vinyl ester market share growth in the pipes and tanks segment will be significant during the forecast period. The growth of the pipes and tanks segment is mainly driven by the increased use of vinyl ester resins in chemical, water, wastewater treatment, and power end-use industries.

This report provides an accurate prediction of the contribution of all the segments to the growth of the vinyl ester market size and actionable market insights on post COVID-19 impact on each segment.

|

Vinyl Ester Market Scope |

|

|

Report Coverage |

Details |

|

Page number |

120 |

|

Base year |

2020 |

|

Forecast period |

2021-2025 |

|

Growth momentum & CAGR |

Accelerate at a CAGR of 3.54% |

|

Market growth 2021-2025 |

$ 350.65 million |

|

Market structure |

Fragmented |

|

YoY growth (%) |

2.60 |

|

Regional analysis |

APAC, North America, Europe, South America, and MEA |

|

Performing market contribution |

APAC at 43% |

|

Key consumer countries |

US, China, Germany, Brazil, and Japan |

|

Competitive landscape |

Leading companies, Competitive strategies, Consumer engagement scope |

|

Key companies profiled |

Allnex Netherlands BV, AOC LLC, Ashland Global Holdings Inc., DIC Corp., Hexion Inc., Interplastic Corp., Orca Composites, Reichhold LLC, SHOWA DENKO K.K., and Swancor Holding Co. Ltd. |

|

Market dynamics |

Parent market analysis, Market growth inducers and obstacles, Fast-growing and slow-growing segment analysis, COVID 19 impact and recovery analysis and future consumer dynamics, Market condition analysis for forecast period |

|

Customization purview |

If our report has not included the data that you are looking for, you can reach out to our analysts and get segments customized. |

What are the Key Data Covered in this Vinyl Ester Market In Regional Report?

- CAGR of the market during the forecast period 2021-2025

- Detailed information on factors that will drive vinyl ester market growth during the next five years

- Precise estimation of the vinyl ester market size and its contribution to the parent market

- Accurate predictions on upcoming trends and changes in consumer behavior

- The growth of the vinyl ester industry across APAC, North America, Europe, South America, and MEA

- A thorough analysis of the market’s competitive landscape and detailed information on vendors

- Comprehensive details of factors that will challenge the growth of vinyl ester market vendors

We can help! Our analysts can customize this report to meet your requirements. Get in touch